Ultrahigh-frequency soft magnetic ferrite material and preparation method of magnetic core

A soft ferrite and ultra-high frequency technology, applied in the field of soft ferrite, can solve the problems of low permeability and high loss, and achieve the effects of high permeability, reduced porosity, and high quality factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides an ultra-high frequency soft ferrite material, including the main components and additive components shown in Table 1 below:

[0039] The composition of the ultra-high frequency low loss soft ferrite material of table 1 embodiment 1:

[0040] The main component is in molar parts, including:

[0041] Fe 2 o 3 67mol

[0042] BaCO 3 25mol

[0043] Flake Co 3 o 4 7mol

[0044] Relative to the total amount of main components, the weight percentages of each additive component are respectively:

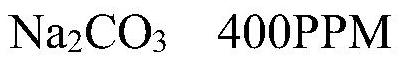

[0045]

[0046]

[0047] The nano-SiO 2 The size is 50-100nm.

[0048] A method for preparing an ultra-high frequency soft ferrite core, comprising the following steps:

[0049]S1, according to the amount of the ultra-high frequency soft magnetic ferrite material described in any of the above, weigh each main component, then mix each main component, and get M type and Y type through wet ball milling, drying, pre-calcination, and grinding B...

Embodiment 2

[0055] The main components are in parts by mole, including:

[0056] Fe 2 o 3 69mol

[0057] BaCO 3 23mol

[0058] Flake Co 3 o 4 9mol

[0059] Relative to the total amount of main components, the weight percentages of each additive component are respectively:

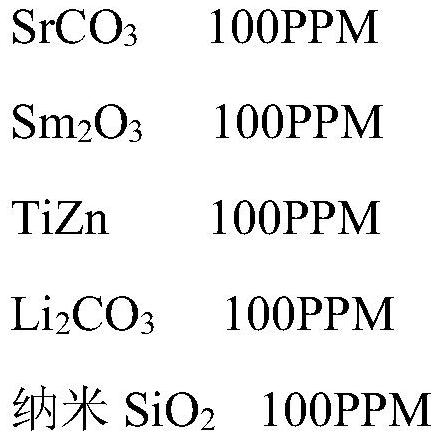

[0060]

[0061] The nano-SiO 2 The size is 50-100nm.

[0062] A method for preparing an ultra-high frequency soft ferrite core, comprising the following steps:

[0063] S1, according to the amount of the ultra-high frequency soft magnetic ferrite material described in any of the above, weigh each main component, then mix each main component, and get M type and Y type through wet ball milling, drying, pre-calcination, and grinding Barium ferrite magnetic powder;

[0064] S2, according to the dosage of the ultra-high frequency soft magnetic ferrite material described in any of the above, weigh each additive component, and weigh the M-type and Y-type barium ferrite magnetic powder obtained in step S1 at a...

Embodiment 3

[0069] The main components are in parts by mole, including:

[0070] Fe 2 o 3 68mol

[0071] BaCO 3 24mol

[0072] Flake Co 3 o 4 8mol

[0073] Relative to the total amount of main components, the weight percentages of each additive component are respectively:

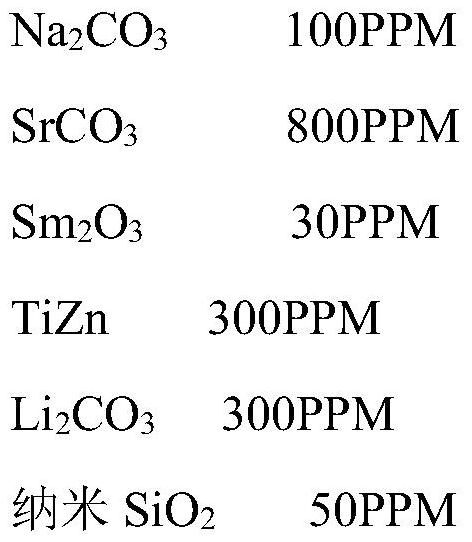

[0074]

[0075] The nano-SiO 2 The size is 50-100nm.

[0076] A method for preparing an ultra-high frequency soft ferrite core, comprising the following steps:

[0077] S1, according to the amount of the ultra-high frequency soft magnetic ferrite material described in any of the above, weigh each main component, then mix each main component, and get M type and Y type through wet ball milling, drying, pre-calcination, and grinding Barium ferrite magnetic powder;

[0078] S2, according to the dosage of the ultra-high frequency soft magnetic ferrite material described in any of the above, weigh each additive component, and weigh the M-type and Y-type barium ferrite magnetic powder obtained in step S1 at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com