Temperature-resistant and corrosion-resistant coating and preparation method thereof

An anti-corrosion coating and temperature-resistant technology, applied in the field of coatings, can solve problems such as poor temperature resistance, and achieve the effects of low VOC content, excellent temperature resistance and anti-corrosion performance, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

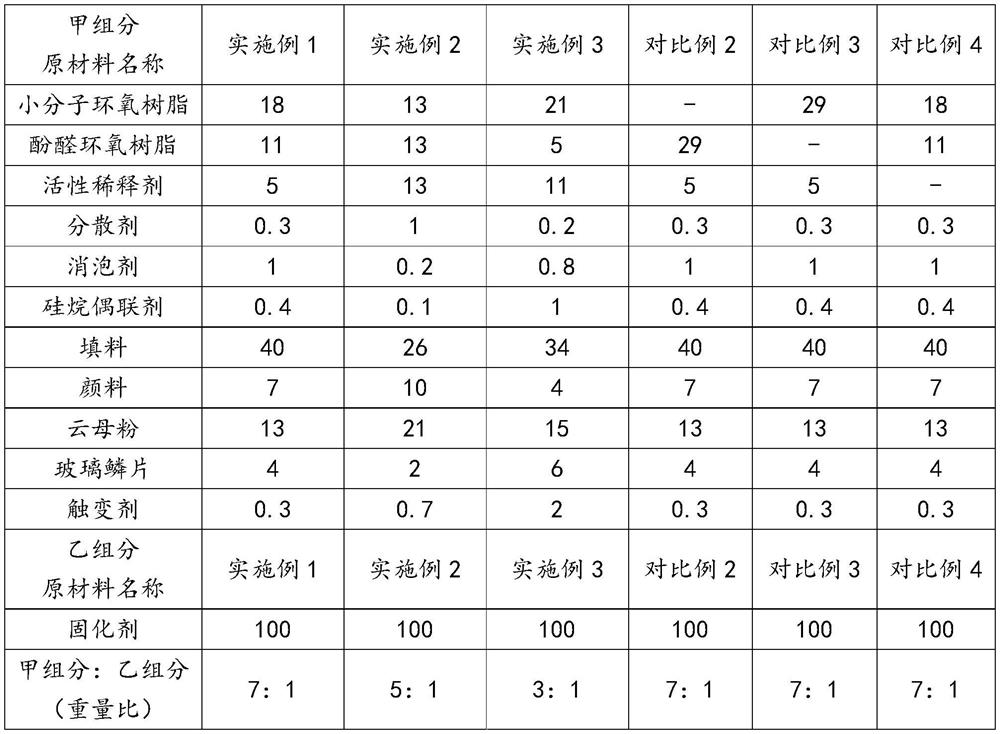

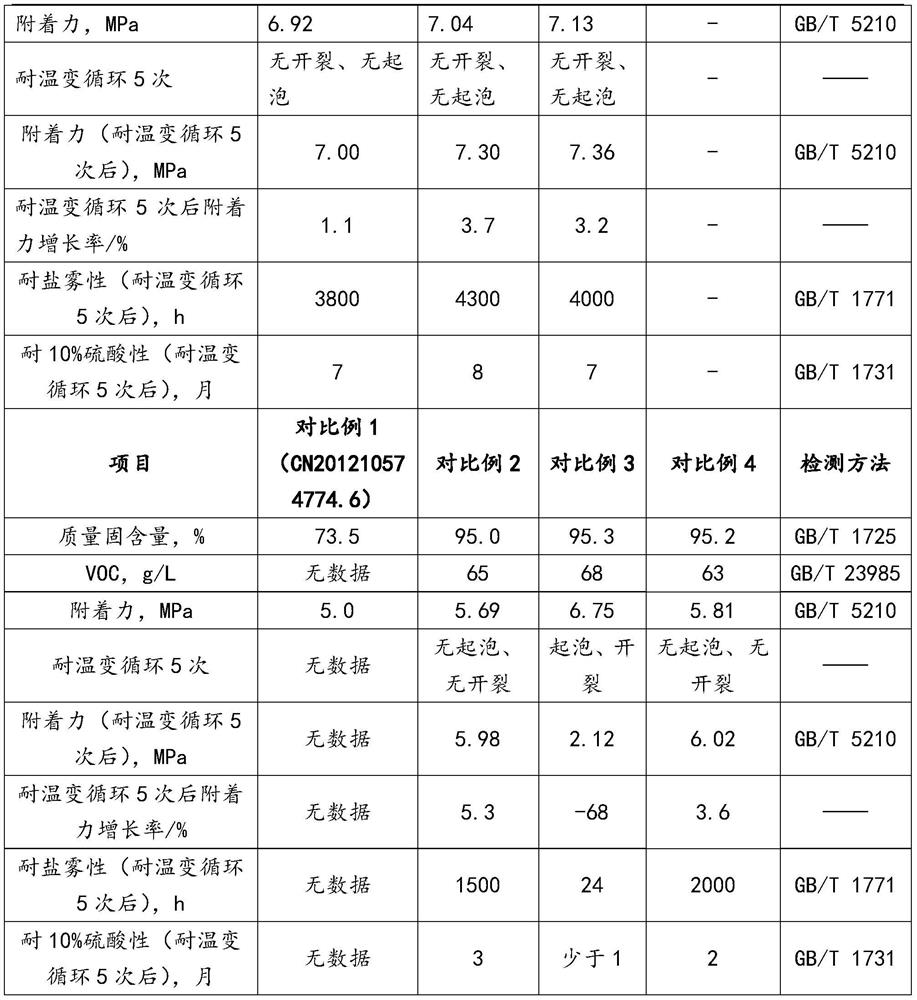

Examples

preparation example Construction

[0046] The present invention also provides a method of preparing the above temperature-resistant anti-corrosion coating, wherein the preparation method of the methyl component comprises the steps of: S100, a small molecule epoxy resin, aphenol epoxy resin, an active diluent, a dispersant, an antifoaming agent And the silane coupling agent is mixed and dispersed uniform; S200, adding filler, pigment, mica powder, and high speed dispersed at high speed to fineness ≤80 μm; S300, while stirring while stirring while stirring while stirring with glass scales And dispersed to uniform; S400, the thixotropic agent was added to the mixture obtained in S300, and dispersed to be uniform, i.e., a component.

[0047] Preferably, in S100, the mixture is dispersed at 300 to 800 rpm of 5 to 15 min.

[0048] Preferably, in S200, the mixture is dispersed at a high speed of 30 to 60 min at 1000 to 1500 rpm until fine is ≤ 80 μm.

[0049] Preferably, in S300, a glass scaned is slowly added to the mixt...

Embodiment 1

[0055] Example 1 Phenolic resin is Miki Group Grade F-51 novolac epoxy resin, novolac epoxy resins Example 2 The Dow Chemical Company as grades embodiment DEN438 novolac epoxy resin, novolac epoxy resin in Example 3 was implemented South sub-brand NPPN-638S phenolic epoxy resin.

[0056] In Example 1 Active diluent was a propylene oxide phenyl ether, and the active diluent in Example 2 was new pentyl glycol dihydrate glycene ether, and the active diluent as an active diluent as an interprephenol dihydrate glycerol ether. Example 1 The filler was a talc, and the fillers in Example 2 were barium precipitated sulfate, and the fillers in Example 3 were crystalline stone powder. Embodiment 1 is made of mica powder, Example 2 and Example 3 using a juniori powder. Examples 1-3 and Comparative Example 2-4 The glass scales having a thickness of 2 μm and a slider size of 150 μm were thick.

[0057] Example 1 The dispersing agent is BYK 110, and in Example 2, the dispersant is BYK 112, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com