Preparation method of high-performance aluminum alloy radiator plate

An aluminum alloy sheet and aluminum alloy technology, which is applied in the field of aluminum alloy sheet manufacturing, can solve the problems of large plate sawing deformation, inconsistent hardness, poor uniform performance, etc., and achieve the effects of reducing internal cracks, uniform structure and improving strength of casting billets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

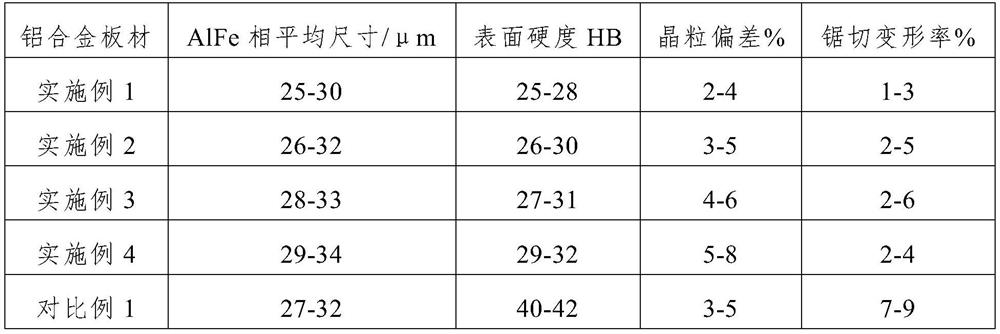

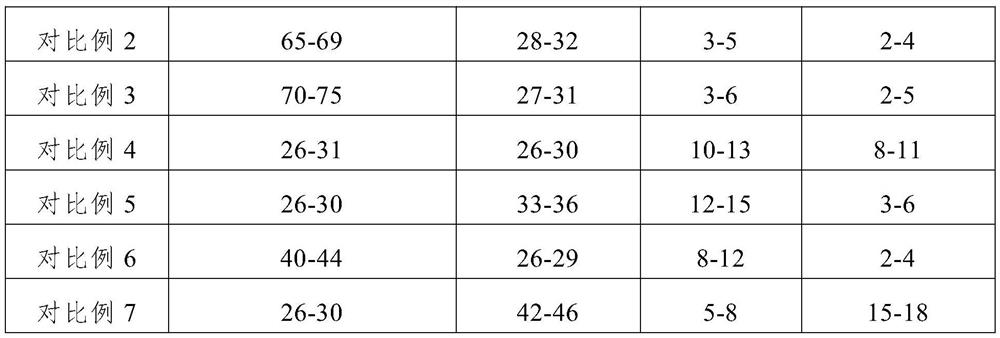

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a high-performance aluminum alloy radiator plate. The alloy composition of the aluminum alloy plate is composed of the following components according to mass percentage: Si: 0.06%, Cu: 0.17%, Fe: 0.12%, Ti: 0.015 %, the balance is Al and unavoidable impurities, wherein Fe:Si mass ratio=2. By controlling the iron-silicon ratio of the main impurity component of the melt to not less than 1.9, the internal cracks of the slab are reduced, the processing deformation rate of the finished product is reduced, and the copper content is controlled to improve the mechanical properties of the aluminum alloy sheet.

[0036] The preparation method of aluminum alloy radiator plate, the steps are as follows:

[0037] (1) Smelting and casting: batching according to the designed alloy composition.

[0038] (2) Cleaning of raw materials: Clean and dry the surface of each raw material to ensure that the raw materials are free of moisture and ...

Embodiment 2

[0049] This embodiment provides a method for preparing a high-performance aluminum alloy radiator plate. The alloy composition of the aluminum alloy plate is composed of the following components according to the mass percentage: Si: 0.07%, Cu: 0.12%, Fe: 0.15%, Ti: 0.015 %, the balance is Al and unavoidable impurities, wherein Fe:Si mass ratio=2.14.

[0050] The preparation method of aluminum alloy radiator plate, the steps are as follows:

[0051] (1) Smelting and casting: batching according to the designed alloy composition.

[0052] (2) Cleaning of raw materials: Clean and dry the surface of each raw material to ensure that the raw materials are free of moisture and debris; when drying, heat at 120°C at a rate of 10°C / min for 2 hours.

[0053] (3) Smelting and casting the aluminum alloy after batching, including:

[0054] When smelting, first raise the speed of 8°C / min to 740°C to make it completely melted, then put in the preheated aluminum-copper alloy, and then lower i...

Embodiment 3

[0063] This embodiment provides a method for preparing a high-performance aluminum alloy radiator plate. The alloy composition of the aluminum alloy plate is composed of the following components according to the mass percentage: Si: 0.065%, Cu: 0.12%, Fe: 0.13%, Ti: 0.015 %, the balance is Al and unavoidable impurities, wherein Fe:Si mass ratio=2.

[0064] The preparation method of aluminum alloy radiator plate, the steps are as follows:

[0065] (1) Smelting and casting: batching according to the designed alloy composition.

[0066] (2) Cleaning of raw materials: Clean and dry the surface of each raw material to ensure that the raw materials are free of moisture and debris; when drying, heat at 120°C at a rate of 10°C / min for 2 hours.

[0067] (3) Smelting and casting the aluminum alloy after batching, including:

[0068] When smelting, first raise the speed of 10°C / min to 740°C to make it completely melted, then put in the preheated aluminum-copper alloy, and then lower it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com