A kind of refining purification method of butanone oxime

A purification method and technology of butanone oxime are applied in the field of refining and purification of butanone oxime, and can solve the problems of carbonization and coking of oxime products, easy char formation and blockage of pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

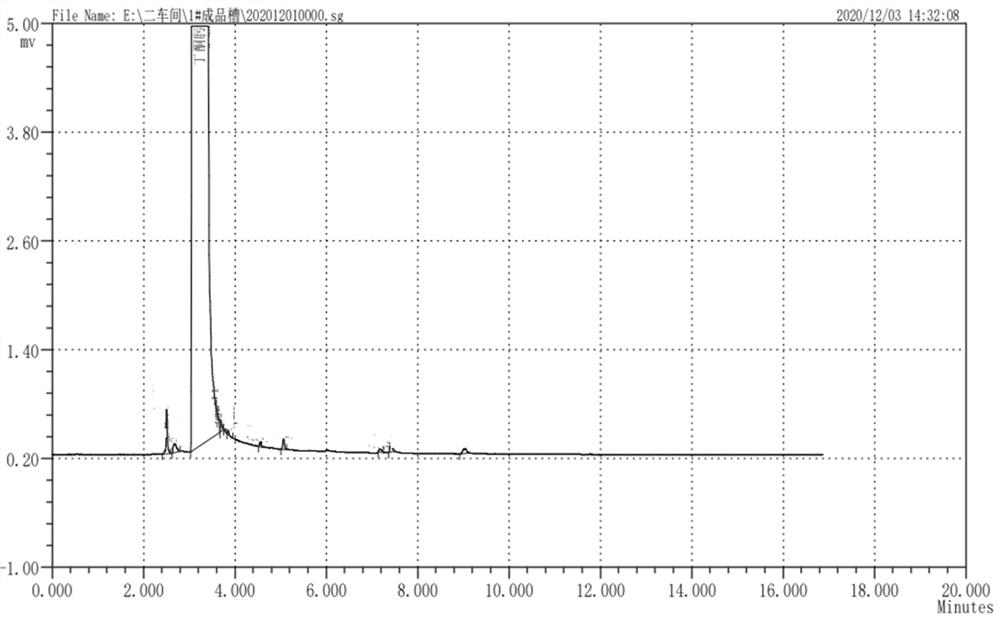

[0025] A refined purification method of butanone oxime, the scheme of which is:

[0026] The 100kg toluene- butanone oxime solution into the organic-inorganic separator, through the centrifuge at a speed of 8000r / min to separate the inorganic phase into the toluene - oxime tank, by the pump pump into the rectification system for separation; the said is a secondary rectification system, toluene - butanone oxime solution first into the middle of the first rectification tower, the internal temperature of the first rectification tower is 120 ° C, the top of the tower reflux temperature is 35 ° C, most of the toluene distilled out of the condensation and reflux to the toluene tank, Butanone oxime crude product from the bottom of the first distillation column into the middle of the second rectification column, the middle temperature of the second rectification column is 115 ° C, toluene distilled out of the condensation reflux to the toluene tank, butanone oxime crude product from the...

Embodiment 2

[0037] A refined purification method of butanone oxime, the scheme of which is:

[0038] 200kg of toluene - butanone oxime solution into the organic inorganic separator, through the centrifuge at a speed of 12000r / min to separate the inorganic phase into the toluene - oxime tank, by the pump pump into the rectification system for separation; the second stage rectification system, toluene - butanone oxime solution first into the middle of the first rectification tower, the internal temperature of the first rectification tower is 128 ° C, the top of the tower reflux temperature is 40 ° C, most of the toluene is distilled out of the condensation and reflux to the toluene tank, Butanone oxime crude product from the bottom of the first distillation column into the middle of the second rectification column, the middle temperature of the second rectification column is 120 ° C, toluene distilled out of the condensation reflux to the toluene tank, butanone oxime crude product from the bo...

Embodiment 3

[0047] A refined purification method of butanone oxime, the scheme of which is:

[0048] The 300kg toluene- butanone oxime solution into the organic inorganic separator, through the centrifuge at a speed of 16000r / min to separate the inorganic phase into the toluene - oxime tank, by the pump pump into the rectification system for separation; the said is the secondary rectification system, toluene - butanone oxime solution first into the middle of the first rectification column, the internal temperature of the first rectification tower is 135 ° C, the top of the tower reflux temperature is 45 ° C, most of the toluene is distilled out of the condensation reflux to the toluene tank, Butanone oxime crude product from the bottom of the first distillation column into the middle of the second rectification column, the middle temperature of the second rectification column is 125 ° C, toluene distilled out of the condensation reflux to the toluene tank, butanone oxime crude product from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com