Method for preparing sucralose

A technology for sucralose and sucrose, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve problems such as hidden safety hazards, labor consumption, complicated steps, etc. The effect of simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

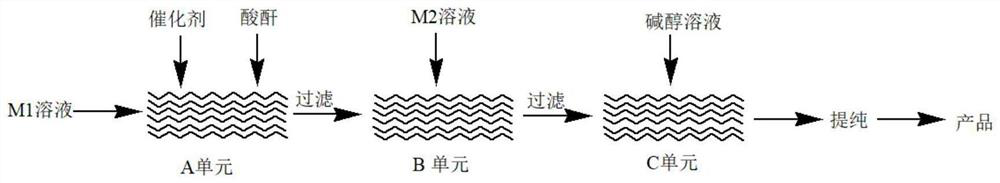

[0025] In the reaction heating kettle, prepare the M1 solution that is formed by heating and dissolving the thionyl chloride of the Vilsmeier reagent with the raw material sucrose until the material liquid is dissolved. The concentration of the M1 solution is 60g / L, and flows into A of the microreactor at a flow rate of 80ml / min. In the unit, in addition, the catalyst and the acid anhydride solution with a concentration of 1.0mol / L flow into the A unit of the microreactor at the flow rate of 5ml / min and 30ml / min respectively. The residence time of the reaction is 60 seconds, and the reaction temperature is controlled at 0 ℃.

[0026] After the reaction solution flows out of the A unit of the microreactor, the DMF feed liquid of the Vilsmeier reagent of the configured 300g / L concentration flows into the B unit of the microreactor simultaneously at a flow rate of 20ml / min, and the residence time of the reaction unit is For 600 seconds, the reaction temperature controlled by the ...

Embodiment 2

[0030] In the reaction heating kettle, prepare the M1 solution formed by heating and dissolving the thionyl chloride of the raw material sucrose with the Vilsmeier reagent until the material liquid is dissolved. The concentration of the M1 solution is 40g / L, and flows into A of the microreactor at a flow rate of 100ml / min. In the unit, in addition, the concentration is 2.0mol / L catalyst, acid anhydride solution flows into the A unit of the microreactor at the flow rate of 10ml / min and 10ml / min respectively, the residence time of this reaction is 300 seconds, and the reaction temperature is controlled at 10 ℃.

[0031] After the reaction solution flows out of the A unit of the microreactor, the DMF feed liquid of the Vilsmeier reagent of the configured 400g / L concentration flows into the B unit of the microreactor simultaneously at a flow rate of 40ml / min, and the residence time of the reaction unit is For 120 seconds, the reaction temperature controlled by the reaction unit wa...

Embodiment 3

[0035] In the reaction heating kettle, prepare the M1 solution formed by heating and dissolving the thionyl chloride of the raw material sucrose with the Vilsmeier reagent until the material liquid is dissolved. The concentration of the M1 solution is 40g / L, and flows into A of the microreactor at a flow rate of 100ml / min. In the unit, in addition, the concentration is 1.0mol / L catalyst, the acid anhydride solution flows into the A unit of the microreactor at the flow rate of 10ml / min and 30ml / min respectively, the residence time of this reaction is 240 seconds, and the reaction temperature is controlled at 5 ℃.

[0036]After the reaction solution flows out of the A unit of the microreactor, the DMF feed liquid of the Vilsmeier reagent of the configured 300g / L concentration flows into the B unit of the microreactor simultaneously at a flow rate of 30ml / min, and the residence time of the reaction unit is For 180 seconds, the reaction temperature controlled by the reaction unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com