Nano-antibacterial sponge with strong water absorption and preparation method thereof

A water-absorbing sponge and nanotechnology, applied in the field of polymer materials, can solve the problems of affecting water absorption and short antibacterial time, and achieve the effect of improving water absorption, fast sterilization rate and long-term antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

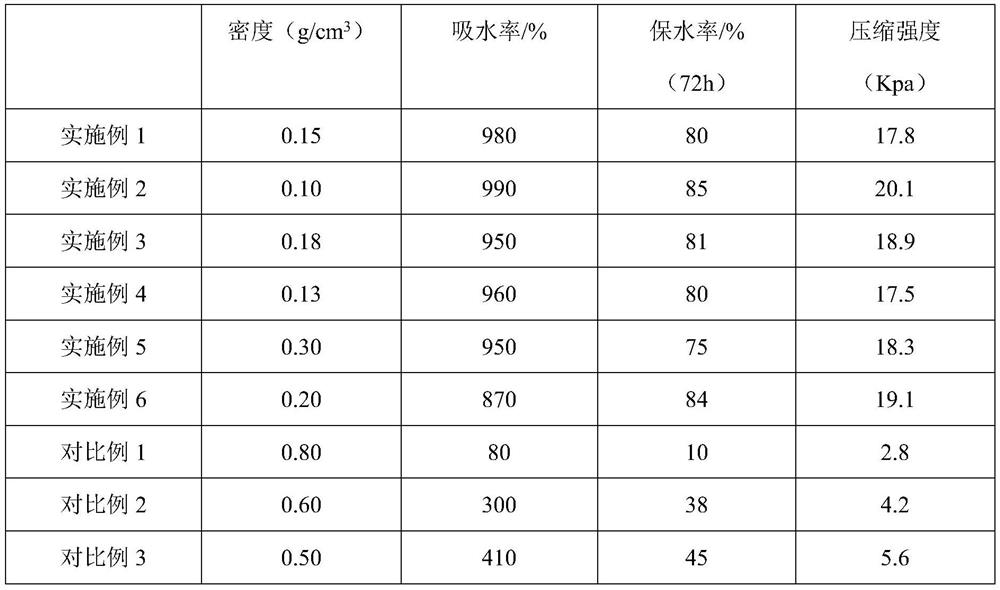

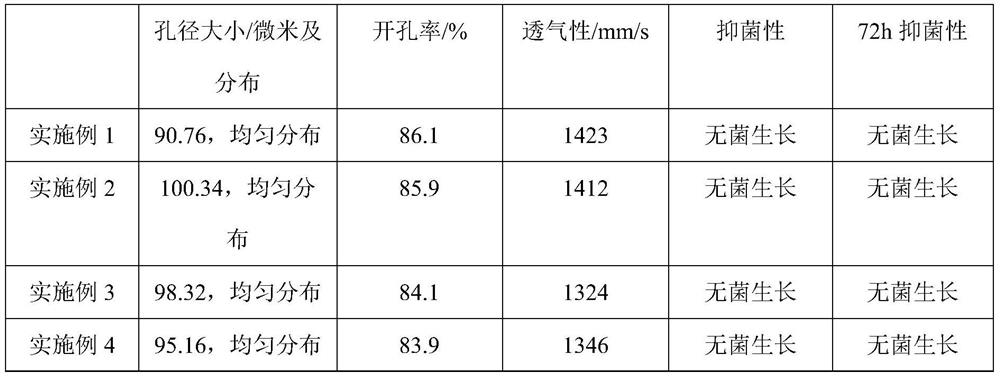

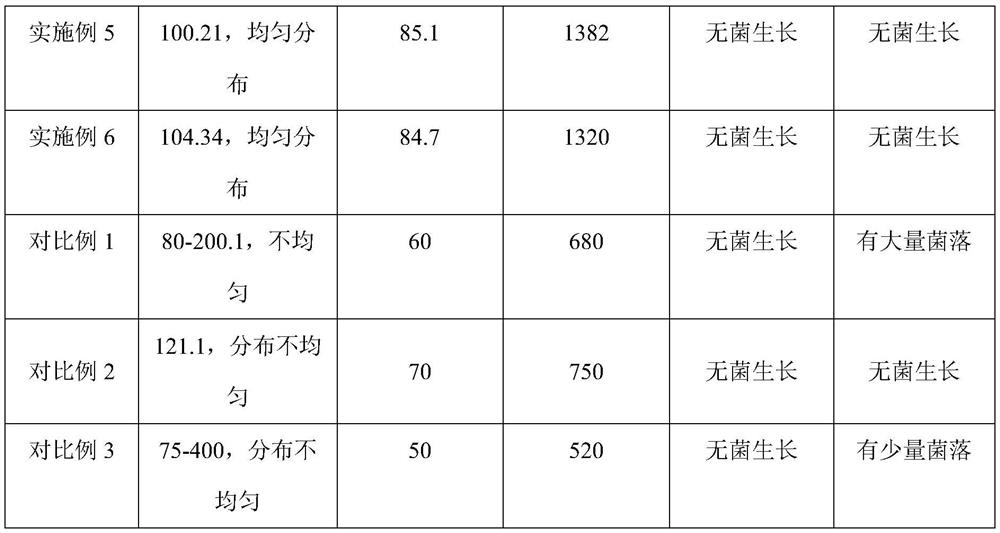

Examples

Embodiment 1

[0032] (1) Accurately weigh 0.2 parts of silicone oil, 0.6 parts of solid amine, 6 parts of water and 3 parts of dimethyl ether, mix and stir evenly;

[0033] (2) 55 parts of polypropylene oxide trihydric alcohol were dehydrated in vacuum at 110°C for 0.5 hours, cooled to 40°C, added to the substance of step (1), and then 0.3 parts of stannous octoate were added, 70°C, 250r / min Stir evenly, cool to 30°C for use;

[0034] (3) Add 30 parts of toluene diisocyanate, 1 part of American Dow Corning DOWSIL7344 additive antibacterial agent and 10 parts of chitosan to the substance of step (2), after stirring at 1400r / min, add 8 parts of sodium alginate, and stir evenly at the same speed and curing at room temperature to obtain the nano antibacterial strong water-absorbing sponge.

Embodiment 2

[0036] (1) Accurately weigh 0.5 parts of silicone oil, 0.5 parts of solid amine, 8 parts of water and 4 parts of dimethyl ether, mix and stir evenly;

[0037] (2) Vacuum dehydrate 60 parts of polyethylene oxide trihydric alcohol at 115°C for 0.8 hours, cool down to 40°C, add to the substance of step (1), then add 0.8 parts of stannous octoate, 75°C, 250r / min Stir evenly, cool to 35°C for use;

[0038] (3) Add 25 parts of toluene diisocyanate, 1 part of American Dow Corning DOWSIL7344 additive antibacterial agent and 12 parts of chitosan to the substance of step (2), after stirring at 1400r / min, add 10 parts of sodium alginate, and stir evenly at the same speed and curing at room temperature to obtain the nano antibacterial strong water-absorbing sponge.

Embodiment 3

[0040] (1) Accurately weigh 1.5 parts of silicone oil, 3 parts of solid amine, 9 parts of water and 5 parts of dimethyl ether, mix and stir evenly;

[0041] (2) Vacuum dehydrate 70 parts of polypropylene oxide triol at 120°C for 0.5 hours, cool down to 50°C, add to the substance of step (1), then add 1.5 parts of stannous octoate, 80°C, 300r / min Stir well, cool to 40°C for use;

[0042] (3) Add 35 parts of toluene diisocyanate, 1 part of American Dow Corning DOWSIL7344 additive antibacterial agent and 15 parts of chitosan to the substance of step (2), after stirring at 1500r / min, add 12 parts of sodium alginate, and stir evenly at the same speed and curing at room temperature to obtain the nano antibacterial strong water-absorbing sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com