Super-hydrophobic coating as well as preparation method and application thereof

A technology of super-hydrophobic coating and super-hydrophobic coating, applied in paper coatings, coatings, coatings without pigments, etc., can solve the problems of reduced application sites, high system viscosity, reduced coating transparency, etc., and achieve the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

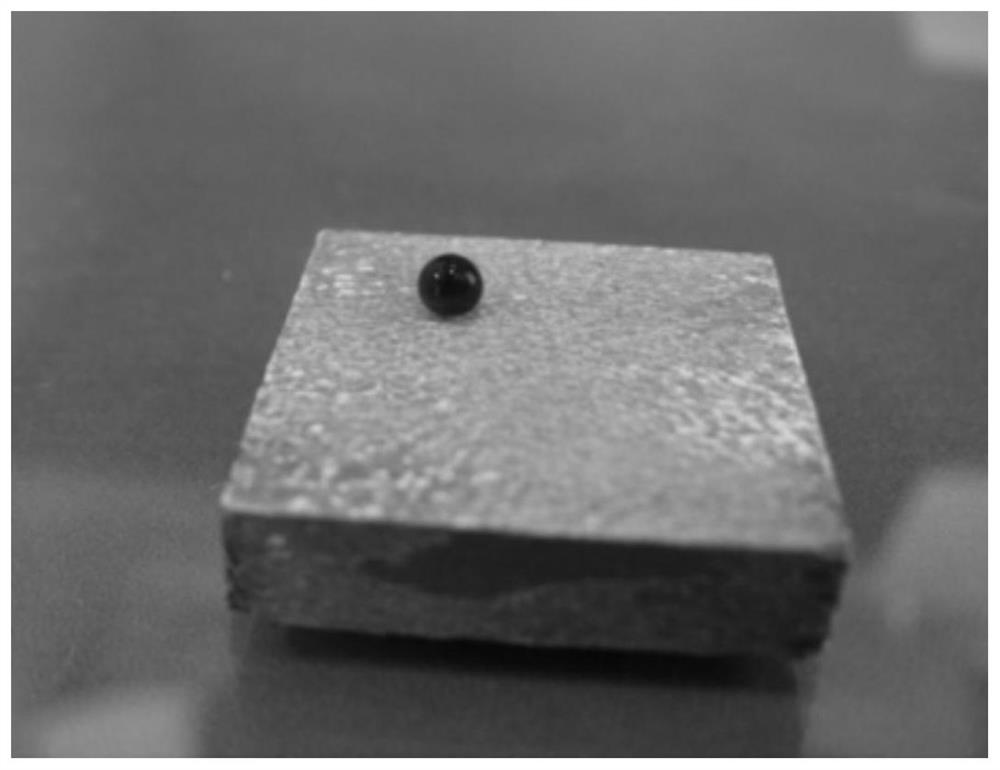

Image

Examples

Embodiment 1

[0087] This embodiment has prepared a kind of super amphiphobic coating, and specific preparation process is:

[0088] First add 20ml of isopropanol, 0.3g of titanium dioxide (100nm), and 3ml of ethanol cyanoacrylate to 5g of dimethyldimethoxysilane in sequence, and stir for 3 minutes to disperse.

[0089] When using the super-hydrophobic coating of this embodiment, a uniform mixed solution can be coated on the surface of the substrate by spin coating.

[0090] Air-dry at 70°C for 2 min, then rinse the coating surface with distilled water and ethanol, and air-dry for 5 min at room temperature to obtain a super-hydrophobic coating.

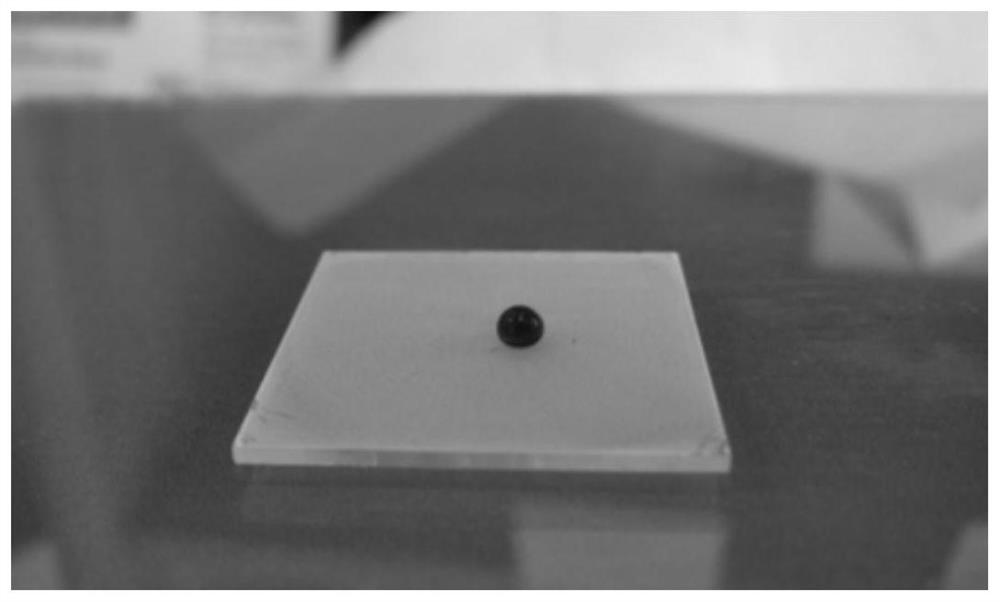

Embodiment 2

[0092] This embodiment has prepared a kind of superhydrophobic coating, and specific preparation process is:

[0093] First add 20ml of isopropanol, 2g of methyltrimethoxysilane, 0.5g of silicon dioxide (100nm), 5ml of ethanol cyanoacrylate into 5g of dimethyldichlorosilane, stir and disperse for 3min, and spray on the glass The surface of the substrate is coated with a uniformly mixed mixture.

[0094] Air-dry at 50°C for 5 minutes, then rinse the coating surface with distilled water and ethanol, and air-dry at 20°C for 3 minutes to obtain a super-hydrophobic coating.

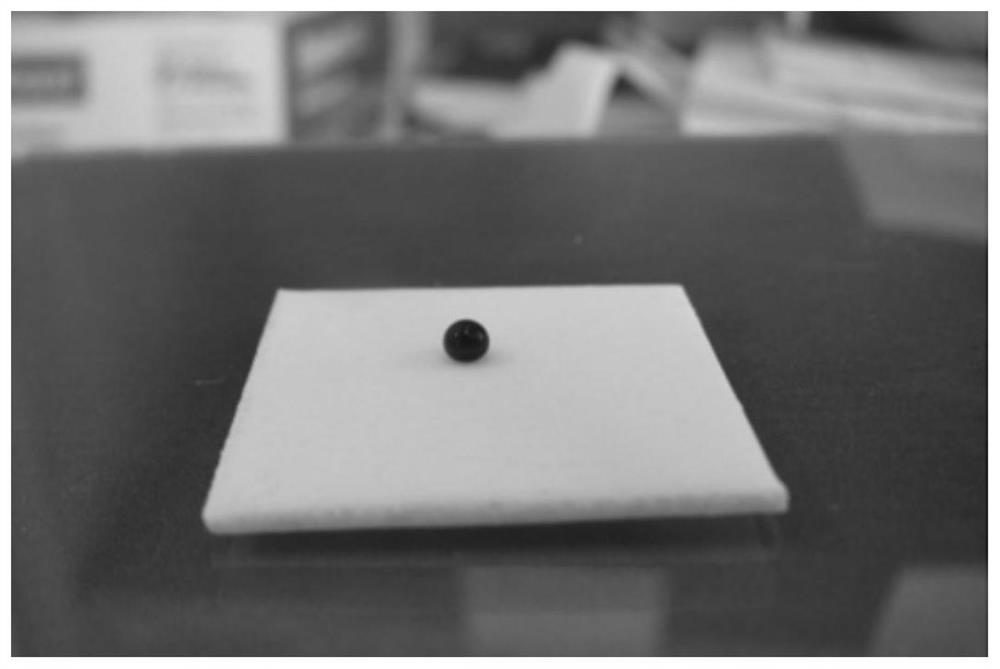

Embodiment 3

[0096] This embodiment has prepared a kind of superhydrophobic coating, and specific preparation process is:

[0097] First add 10ml of toluene, 0.6g of silicon dioxide (100nm), and 1.2g of epoxy acrylate to 5g of dimethyldichlorosilane in sequence, stir and disperse for 3 minutes, and coat and mix evenly on the surface of the substrate by dip coating liquid.

[0098] Air-dry at 25°C for 5 minutes, then rinse the coating surface with distilled water and ethanol, and air-dry at 20°C for 10 minutes to obtain a super-hydrophobic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com