Thickened oil viscosity reducer and application thereof

A technology of viscosity reducer and heavy oil, applied in wellbore/well components, production fluids, iron-organic compounds, etc., can solve the problems of poor viscosity reduction effect of viscosity reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

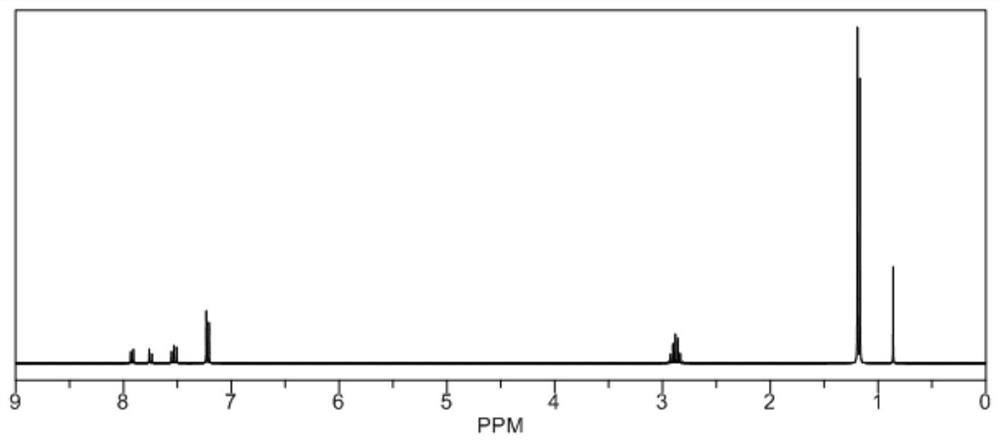

Image

Examples

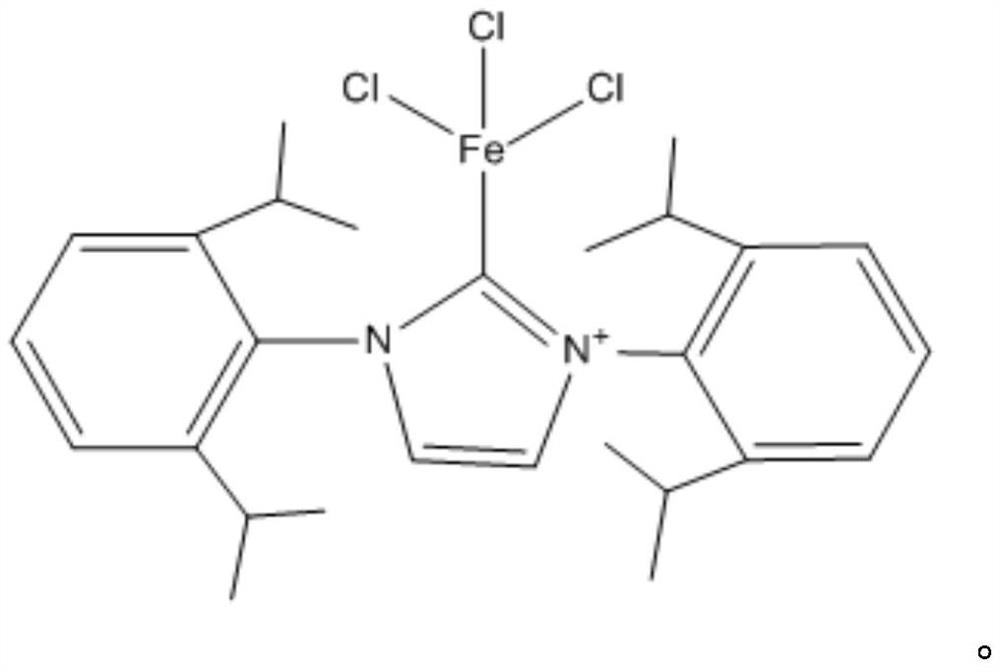

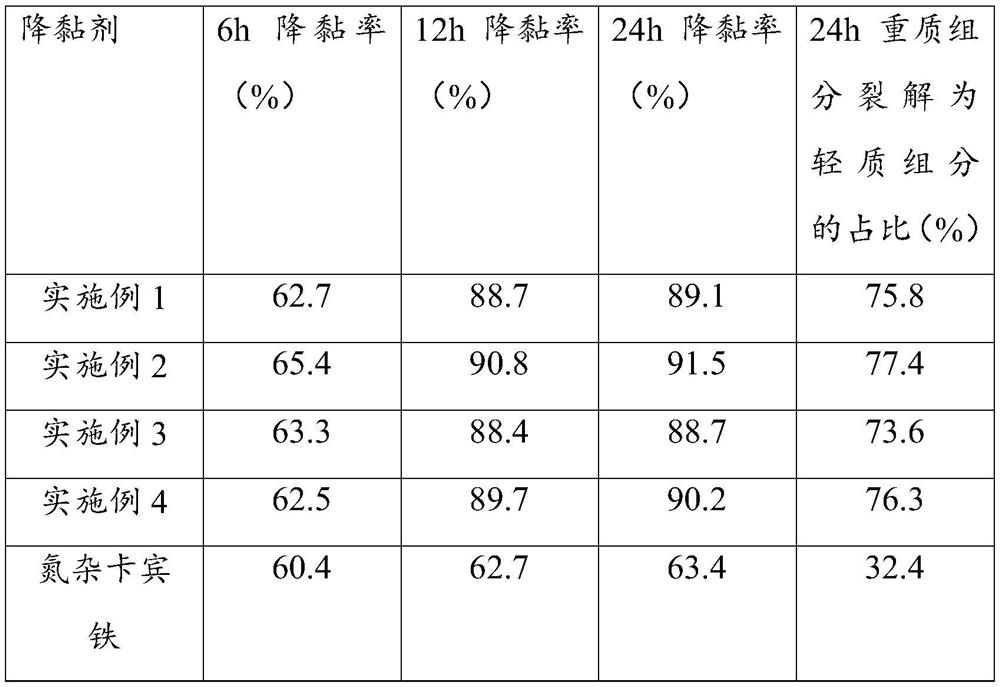

Embodiment 1

[0031] This embodiment proposes a viscous reducer for heavy oil, which includes the following components based on mass percentage: azacarbene iron 8wt%, oxidant tert-butyl hydroperoxide 15wt%, hydrogen donor methanol 3wt%, phosphoric acid 5wt%, The mixture of emulsifier Tween 20 and Span 20 is 0.5wt%, alkali sodium hydroxide is 1wt%, and the rest is solvent benzene, the total is 100%; the mass ratio of Tween 20 and Span 20 is 0.12:1.

Embodiment 2

[0033] This embodiment proposes a thick oil viscosity reducer, which includes the following components according to the mass percentage: azacarbene iron 10wt%, oxidizing agent KIO 4 30 wt%, hydrogen donor ethanol 5wt%, phosphoric acid 6wt%, emulsifier Tween 20 and Span 20 mixture 0.8wt%, alkali sodium hydroxide 1.2wt%, the rest is solvent toluene, 100% in total; of which Tween The mass ratio of 20 and Span 20 is 0.15:1.

Embodiment 3

[0035] This embodiment proposes a thick oil viscosity reducer, which includes the following components according to the mass percentage: azacarbene iron 5wt%, oxidant KMnO 4 20 wt%, hydrogen donor methanol 1wt%, phosphoric acid 10wt%, emulsifier Tween 20 1wt%, alkali sodium hydroxide 1wt%, and the rest is solvent xylene, 100% in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com