Cobalt oxide-hydroxylated single-walled carbon nanotube composite material and preparation and application thereof

A technology of single-walled carbon nanotubes and single-walled nanotubes, applied in the direction of carbon nanotubes, cobalt oxide/cobalt hydroxide, nano-carbon, etc., can solve problems such as poor dispersion, inability to form a uniform electrode modification layer, and easy agglomeration. Achieve the effect of improving electrical conductivity, excellent selectivity, and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

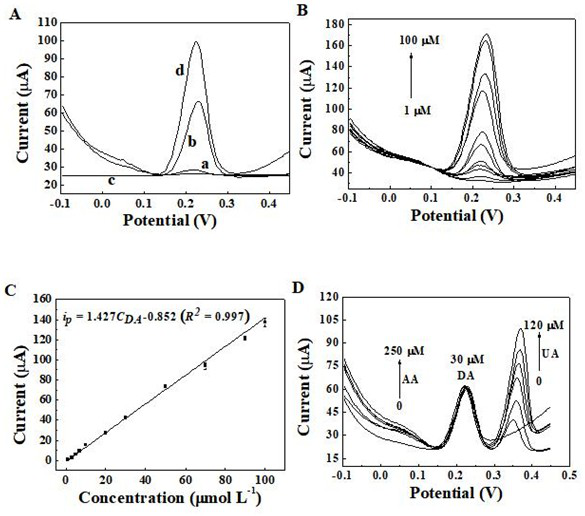

[0025] A preparation method of cobalt oxide / hydroxylated single-walled carbon nanotube modified electrode, comprising the following steps:

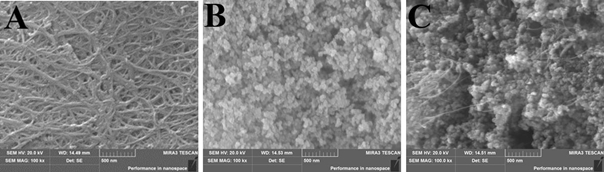

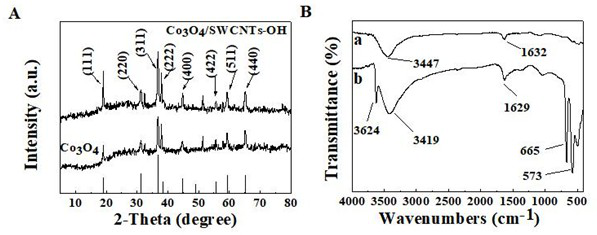

[0026] S1. Preparation of cobalt oxide nanoparticles: Mix 0.5 mmol of cobalt nitrate hexahydrate solution with 12 mmol of ammonia water, stir at room temperature (25 °C) for 1 hour, then transfer to the reactor, and conduct hydrothermal reaction at 140 °C for 6 h , after cooling to room temperature, the product was collected, washed with ultrapure water, and dried at 60 °C for 12 h to obtain the cobalt oxide nanoparticles;

[0027] S2. Preparation of hydroxylated single-walled carbon nanotubes: Add 200 mg of SWCNTs to 50 mL of 30% aqueous hydrogen peroxide solution using a condensing reflux device, and stir the reaction at 100 °C for 4 h. After repeated washing with pure water, the reaction precipitate was collected and freeze-dried at -50°C for 24 h to obtain the hydroxylated single-walled carbon nanotubes;

[0028] S3. Preparation of c...

Embodiment 2

[0031] A preparation method of cobalt oxide / hydroxylated single-walled carbon nanotube modified electrode, comprising the following steps:

[0032]S1. Preparation of cobalt oxide nanoparticles: Mix 0.5 mmol of cobalt nitrate hexahydrate solution with 1 mmol of ammonia water, stir at room temperature (25 °C) for 3 hours, then transfer to a reaction kettle, and conduct a hydrothermal reaction at 180 °C for 4 h , after cooling to room temperature, the product was collected, washed with ultrapure water, and dried at 60 °C for 12 h to obtain the cobalt oxide nanoparticles;

[0033] S2. Preparation of hydroxylated single-walled carbon nanotubes: Add 50 mg of SWCNTs to 100 mL of 30% aqueous hydrogen peroxide solution using a condensing reflux device, and stir the reaction at 100 °C for 4 h. After repeated washing with pure water, the reaction precipitate was collected and freeze-dried at -50°C for 24 h to obtain the hydroxylated single-walled carbon nanotubes;

[0034] S3. Preparati...

Embodiment 3

[0037] A preparation method of cobalt oxide / hydroxylated single-walled carbon nanotube modified electrode, comprising the following steps:

[0038] S1. Preparation of cobalt oxide nanoparticles: Mix 0.5 mmol of cobalt nitrate hexahydrate solution with 2 mmol of ammonia water, stir at room temperature (25 °C) for 2 hours, then transfer to the reactor, and conduct a hydrothermal reaction at 120 °C for 8 h , after cooling to room temperature, the product was collected, washed with ultrapure water, and dried at 60 °C for 12 h to obtain the cobalt oxide nanoparticles;

[0039] S2. Preparation of hydroxylated single-walled carbon nanotubes: Add 50 mg of SWCNTs to 100 mL of 30% aqueous hydrogen peroxide solution using a condensing reflux device, and stir the reaction at 100 °C for 2 h. After repeated washing with pure water, the reaction precipitate was collected and freeze-dried at -50°C for 24 h to obtain the hydroxylated single-walled carbon nanotubes;

[0040] S3. Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com