Method for extracting iron and cobalt from iron tailings of neodymium iron boron waste hydrochloric acid optimal solution method

An iron tailings, NdFeB technology, applied in the direction of improving process efficiency, can solve the problems of high price of organic additives, low leaching rate, high energy consumption, achieve significant economic and environmental benefits, reduce impurities separation operations, The effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

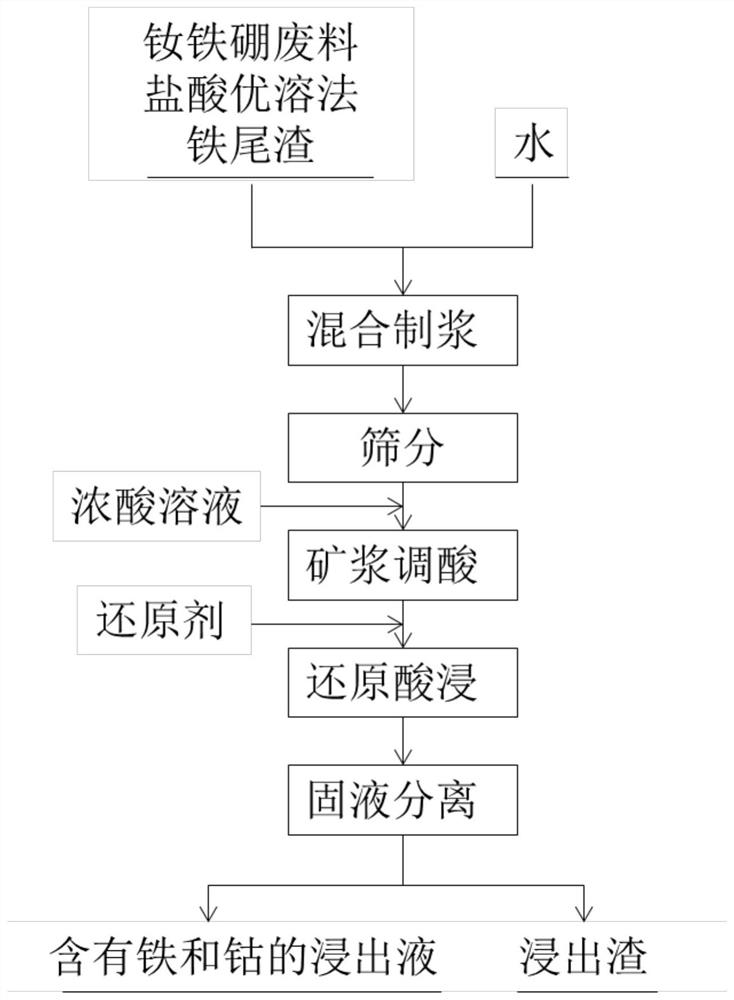

[0057] This embodiment provides a method for extracting iron and cobalt from NdFeB waste hydrochloric acid excellent solution iron tailings, and the process flow chart of the method is as follows figure 1 shown.

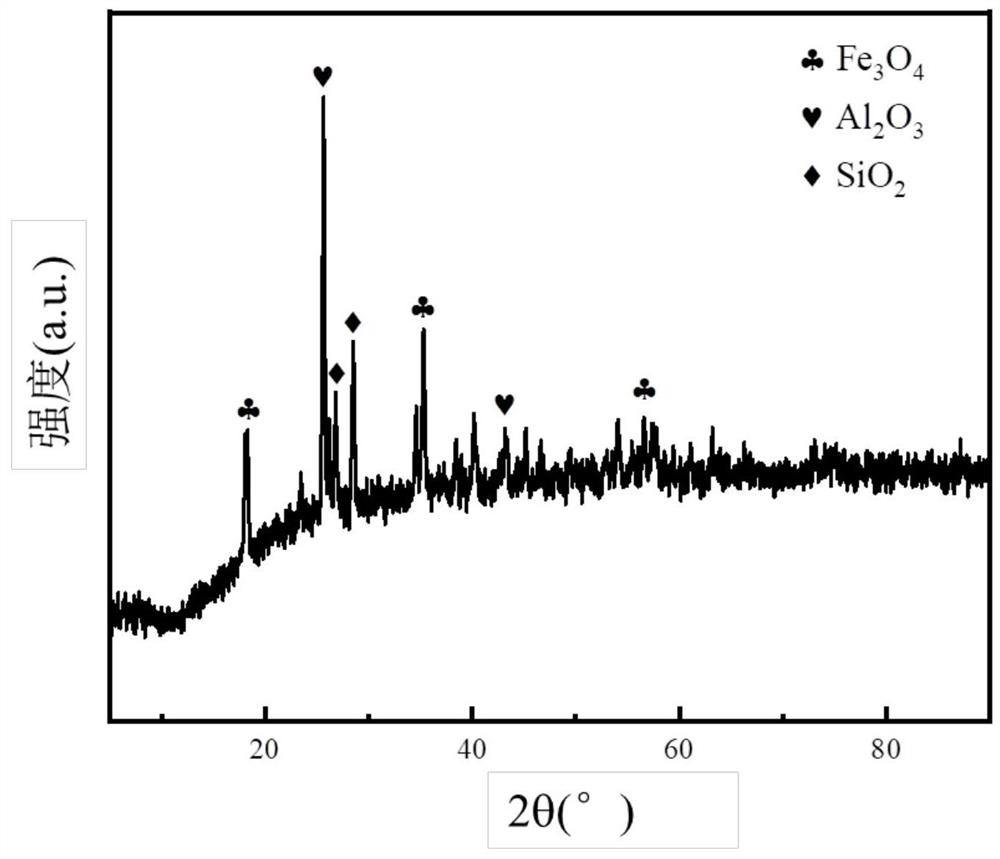

[0058] The composition of the iron tailings that the present embodiment adopts is as shown in table 1, and its XRD figure is as follows figure 2 shown.

[0059] Table 1

[0060] Element Fe 2 o 3

CoO SiO 2

CaO ZnO Al 2 o 3

content 72.06 0.51 15.30 0.31 0.17 5.42

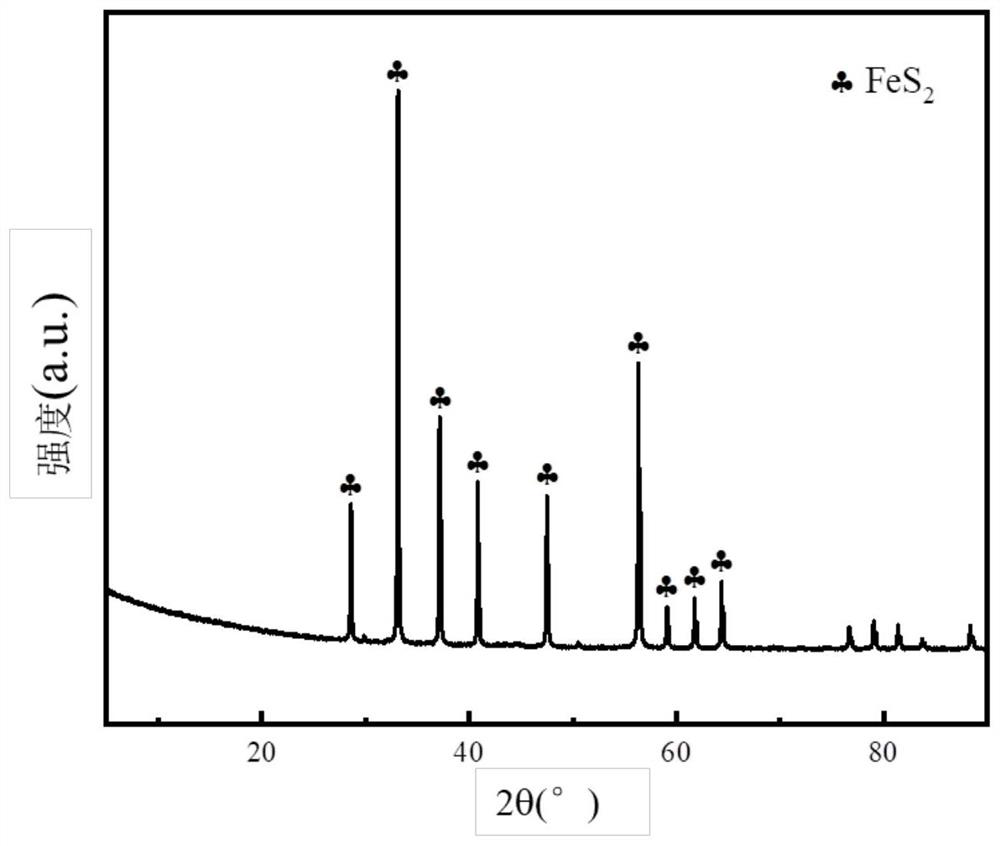

[0061] The composition of the reductant-pyrite that the present embodiment adopts is as shown in table 2, and its XRD figure is as follows image 3 shown.

[0062] Table 2

[0063] Element Fe S SiO 2

Al 2 o 3

content 42.34 44.27 3.37 0.74

[0064] The method comprises the steps of:

[0065] (1) Tailings pulping: Sieve the iron tailings to obtain particles with a particle size not greater than 4mm for use; mix...

Embodiment 2

[0069] This embodiment provides a method for extracting iron and cobalt from the iron tailings of the NdFeB waste hydrochloric acid excellent solution method, and the iron tailings used in it have the same composition as that in Example 1.

[0070] The method comprises the steps of:

[0071] (1) Tailings pulping: Sieve the iron tailings to obtain particles with a particle size not greater than 4mm for use; mix 10kg of iron tailings particles with 15kg of water, stir thoroughly for 60 minutes and pass through a 5-mesh screen to obtain dispersion Ore slurry; after drying the residue on the mesh screen, the measured quality is 0.17kg, and 0.17kg of iron tailing particles to be used is added to the dispersed ore slurry;

[0072] (2) Ore pulp acid adjustment: add 19kg, the concentrated sulfuric acid that massfraction is 98wt% in the dispersed ore pulp that step (1) obtains under stirring state, make the concentrated sulfuric acid concentration in the dispersed ore slurry liquid pha...

Embodiment 3

[0075] This embodiment provides a method for extracting iron and cobalt from the iron tailings of the NdFeB waste hydrochloric acid excellent solution method, and the iron tailings used in it have the same composition as that in Example 1.

[0076] The method comprises the steps of:

[0077] (1) Tailings pulping: Sieve the iron tailings to obtain particles with a particle size not greater than 4mm for use; mix 10kg of iron tailings particles with 10kg of water, stir thoroughly for 60 minutes and pass through a 5-mesh screen to obtain dispersion Ore slurry; after drying the residue on the mesh screen, the measured quality is 0.52kg, and 0.52kg of iron tailing particles to be used is added to the dispersed ore slurry;

[0078] (2) acid adjustment of ore pulp: add 16.2kg, massfraction is the vitriol oil of 98wt% in the dispersed ore pulp that step (1) obtains under stirring state, the concentrated sulfuric acid concentration in the dispersed ore slurry liquid phase is adjusted to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com