Silicon-based molecular sieve confinement oxygen reduction Me-N-C catalyst and preparation method thereof

A catalyst and molecular sieve technology, applied in the field of electrocatalysis, can solve the problems of easy decomposition and poor stability, and achieve the effect of strong catalytic activity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

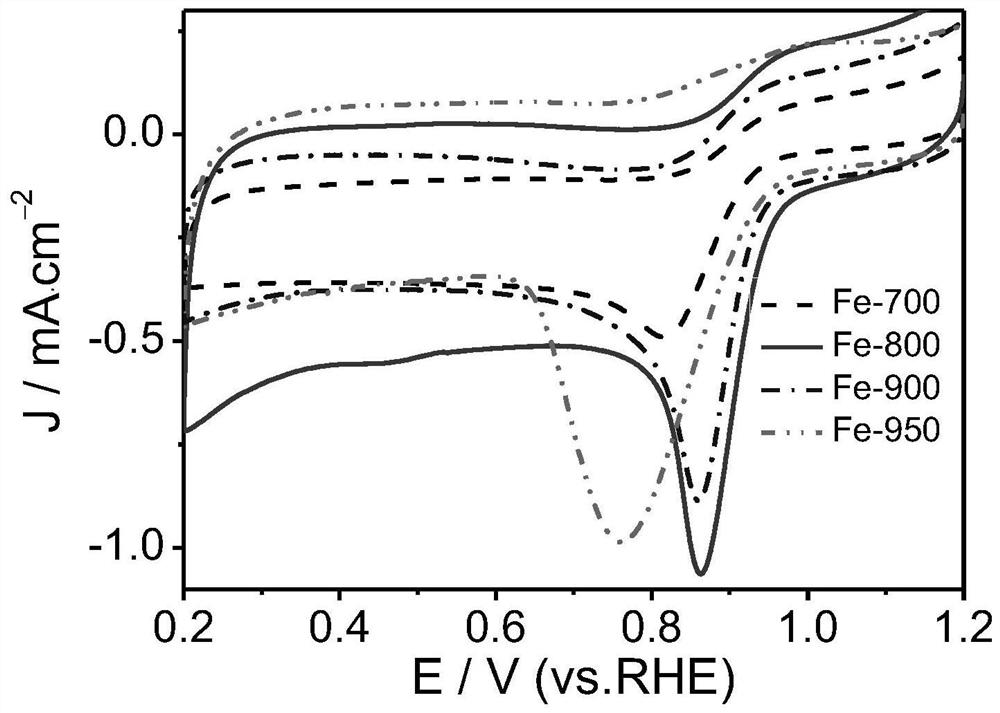

[0038] The present invention also provides a preparation process for the catalyst, specifically comprising the following steps:

[0039] 1. According to the molar ratio of transition metal and TPTZ is 1:3, mix the transition metal and TPTZ evenly.

[0040] 2. Then add 20 mL of 0.2 mol / L HCl, dissolve and stir for 5 hours to form a complex. Then add molecular sieve (SiO 2 ), stirred at room temperature for 24 hours, allowing the complex to fully enter the aperture of the molecular sieve.

[0041] 3. Put the product obtained in step 2 into an oven, and raise the temperature of the oven step by step to 800-950°C under the protection of nitrogen (specifically: raise the temperature to the required temperature at a rate of 10°C / min), and then Keep warm for two hours. Then cool naturally to room temperature, take out the medicine, and obtain the required catalyst, grind and pack it into bags.

[0042] 4. The samples of each treatment group in step 3 are ultrasonically cleaned (3...

Embodiment 1

[0044] Embodiment one: prepare the catalyst of different transition metals

[0045] 1. Weigh 6 parts of tripyridine triazine (hereinafter referred to as: TPTZ), each 0.2g, as 6 treatments. The molecular formula of TPTZ is as follows:

[0046]

[0047] According to the molar ratio of added material and TPTZ is 1:3, add 5 kinds of different materials respectively in the TPTZ of each treatment; 2 Cl 2 ), treatment 2: 0.03631g copper chloride (CuCl 2 ), treatment 3: 0.05062g nickel chloride (NiCl 2 ), treatment 4: 0.04215g manganese chloride (MnCl 2 ), treatment 5: 0.02903g zinc chloride (ZnCl 2 ); leave another treatment as a blank group, treatment 6.

[0048] 2. Precursor preparation: Add 20 mL of 0.2 mol / L HCl to the above 6 groups of treatments, dissolve and stir for 5 hours to form a complex. Then add 0.2g of molecular sieve (SiO 2 ), stirred at room temperature for 24 hours, allowing the complex to fully enter the aperture of the molecular sieve.

[0049] 3. Put ...

Embodiment 2

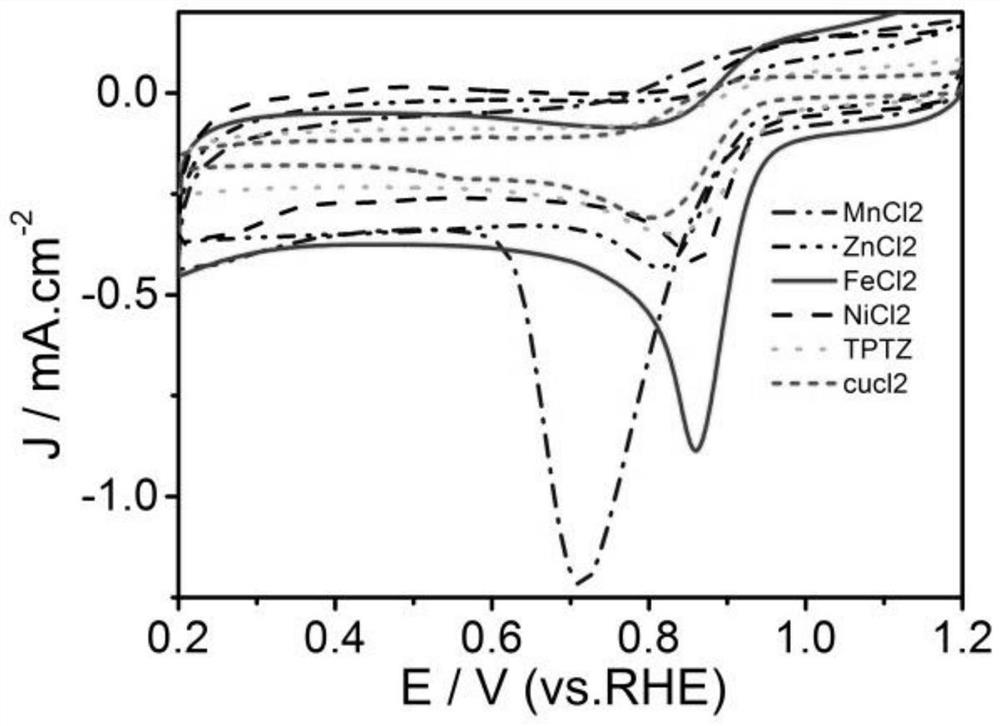

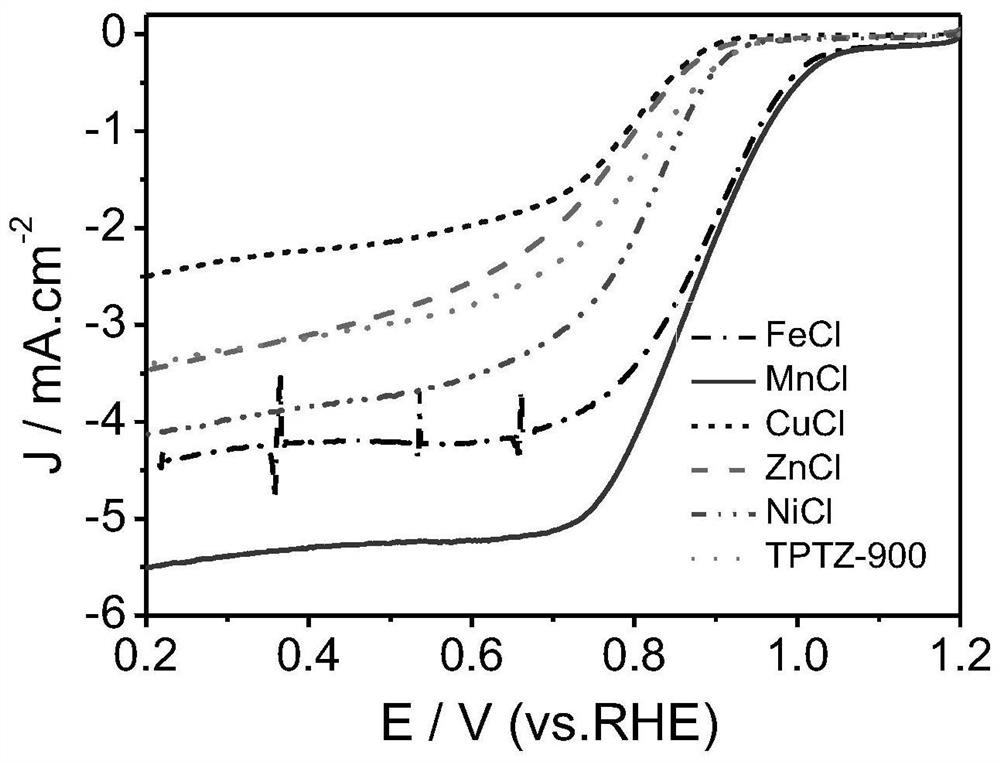

[0051] Example 2: Performance testing and morphology characterization of different transition metal catalysts

[0052] 1. Electrochemical performance test.

[0053] (1) Weigh 1mg samples of Fe-C-N-900, Cu-C-N-900, NiC-N-900, Mn-C-N-900, and Zn-C-N-900 respectively, put them in 0.5mL sample tubes, and add 90μL distilled water and 10 μL of 0.5 mol / L naphthalene solution, and ultrasonically mix evenly to obtain a mixed solution. Use a pipette gun to pipette 10 μL of the mixed solution on the surface of the glassy carbon electrode, and place it to dry to obtain an electrode.

[0054] (2) After the electrode is dry, place the electrode in the 0.1mol / L KOH electrolyte solution prepared in advance, and oxygenate it for a period of time. Connect the circuit according to the correct circuit connection method, and then turn on the electrochemical workstation for electrochemical testing to detect the ORR catalytic activity of the sample.

[0055] And simultaneously prepare a series of p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap