Method for preparing magnetic polymer microspheres and application thereof

A technology of polymers and microspheres, applied in the field of biochemistry, can solve the problems of affecting enzymatic reactions, fluid manipulation restricts the use of technology, and is difficult to carry out, so as to achieve the effect of high-throughput biochemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

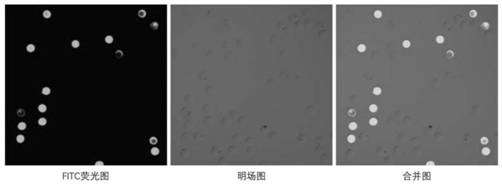

[0083] A method for preparing magnetic polymer microspheres, the preparation process is as follows figure 2 As shown in a-2c, it includes the following steps:

[0084] 1) Firstly, polyacrylamide soluble gel microspheres were prepared by microfluidic technology, specifically, N,N, HFE-7500 fluorinated oil phase of N',N'-tetramethylethane-1,2-diamine (TEMED) and 2% g / mL surfactant (PEG-PFPE); second flow input channel Input a mixed aqueous solution containing 6% g / mL acrylamide monomer, 0.392% g / mL N,N'-bis(acryloyl) cystamine and 0.6% g / mL ammonium persulfate; the third output of the microfluidic chip Channels collect soluble gel microdroplets. Place the collected droplets at room temperature for 7 hours to form a gel. After forming the gel, de-emulsify the micro-droplets, and then use HFE-7500 fluorinated oil containing 20% v / v 1H, 1H, 2H, 2H-Perfluorooctanol Wash once, wash twice with n-hexane containing 1% v / v Span-80, wash twice with TE buffer containing 0.1% v / v Trit...

Embodiment 2

[0088] A method for preparing magnetic polymer microspheres, the preparation process is as follows figure 2 As shown in a-2c, it includes the following steps:

[0089] 1) Firstly, polyacrylamide soluble gel microspheres were prepared using microfluidic technology, and the preparation process was the same as step 1 of Example 1);

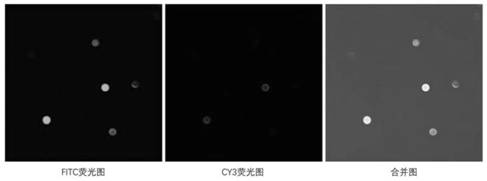

[0090] 2) Using microfluidic technology to prepare double-layer gel microspheres wrapped with a magnetic layer (the outer layer is polyethylene glycol gel wrapped with magnetic nanoparticles, and the inner layer is polyacrylamide gel), specifically, to Such as image 3 The first flow input channel of the microfluidic chip shown contains 0.4% v / v N,N,N',N'-tetramethylethane-1,2-diamine (TEMED) and 2% g / mL surfactant (PEG-PFPE) HFE-7500 fluorinated oil oil phase, the second flow input channel input containing 5% g / mL polyethylene glycol, 0.6% g / mL ammonium persulfate and trioxide The polyethylene glycol gel solution of ferromagnetic nanoparticles;...

Embodiment 3

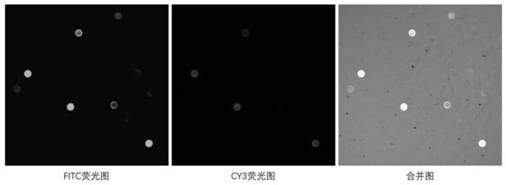

[0093] A method for preparing magnetic polymer microspheres, the preparation process is as follows figure 2 As shown in a-2c, it includes the following steps:

[0094] 1) First, prepare soluble polyacrylamide gel microspheres using microfluidic technology, and the preparation process is the same as step 1 of Example 1);

[0095] 2) Using microfluidic technology to prepare double-layer gel microspheres wrapped with a magnetic layer (the outer layer is agarose gel wrapped with magnetic nanoparticles, and the inner layer is polyacrylamide gel), specifically, to such as image 3 The first flow input channel of the shown microfluidic chip inputs HFE-7500 fluorinated oil oil phase containing 2% g / mL surfactant (PEG-PFPE); the second flow input channel input contains 2% g / mL Agarose and agarose solution containing ferroferric oxide magnetic nanoparticles (agarose was dissolved completely at 90°C for 30 minutes); the third flow input channel input the soluble gel microspheres prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com