Preparation method of paper diaper antibacterial plastic packaging bag

A technology of antibacterial plastics and diapers, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of poor antibacterial ability and easy breeding of bacteria, and achieve the effect of improving structural stability and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

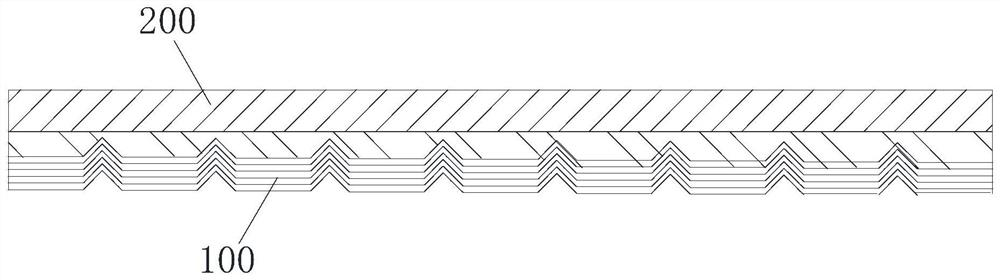

[0040] This embodiment discloses an antibacterial plastic packaging bag for diapers, comprising a plastic film layer 100 and an antibacterial nonwoven fabric layer 200, wherein the antibacterial nonwoven fabric layer 100 includes the following materials in parts by weight:

[0041]

[0042] The antibacterial non-woven fabric layer is provided with a stretchable structure along its length direction to cooperate with the deformation of the plastic film layer by external force.

Embodiment 2

[0044] This embodiment discloses the preparation method of the antibacterial plastic packaging bag for diapers in Example 1, in which the antibacterial non-woven fabric layer is bonded to the surface of the plastic film layer through acrylic resin;

[0045] The antibacterial nonwoven layer is prepared by the following steps:

[0046] Step 1, mix the fibers, polyvinyl alcohol fibers, oleic acid, chitosan and nanocellulose according to the mass parts to prepare master batches, and slice them for later use;

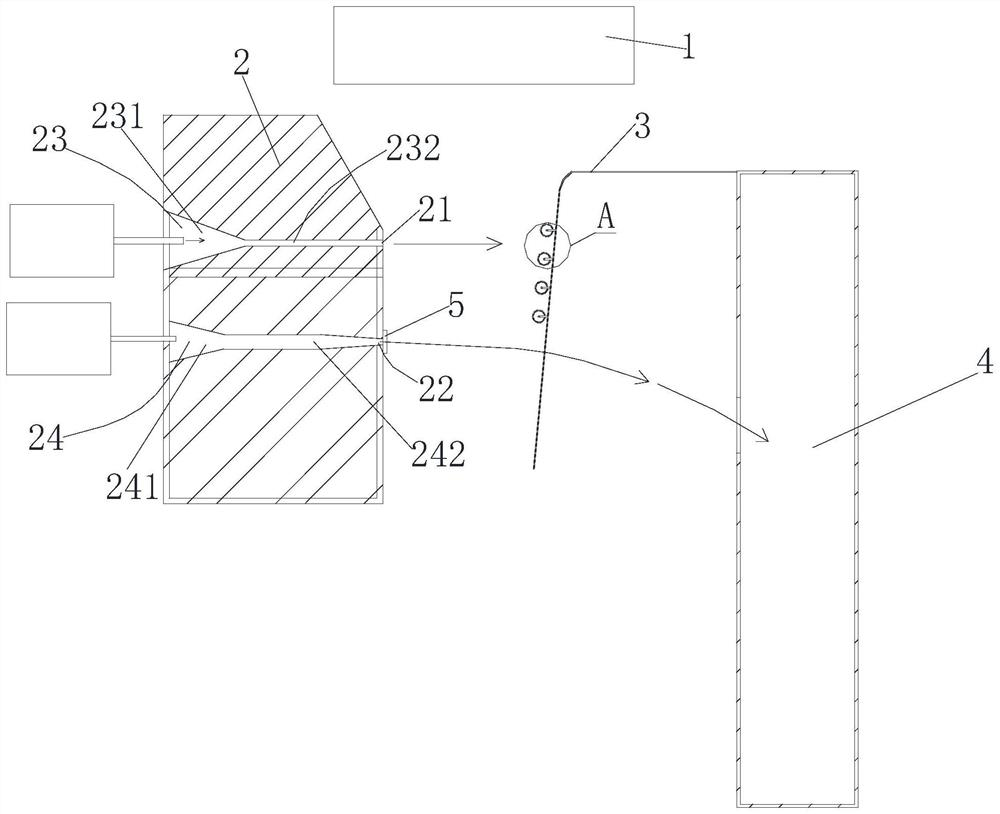

[0047] Step 2, the chips obtained in Step 1 are passed through a screw extruder 1 to obtain fibers;

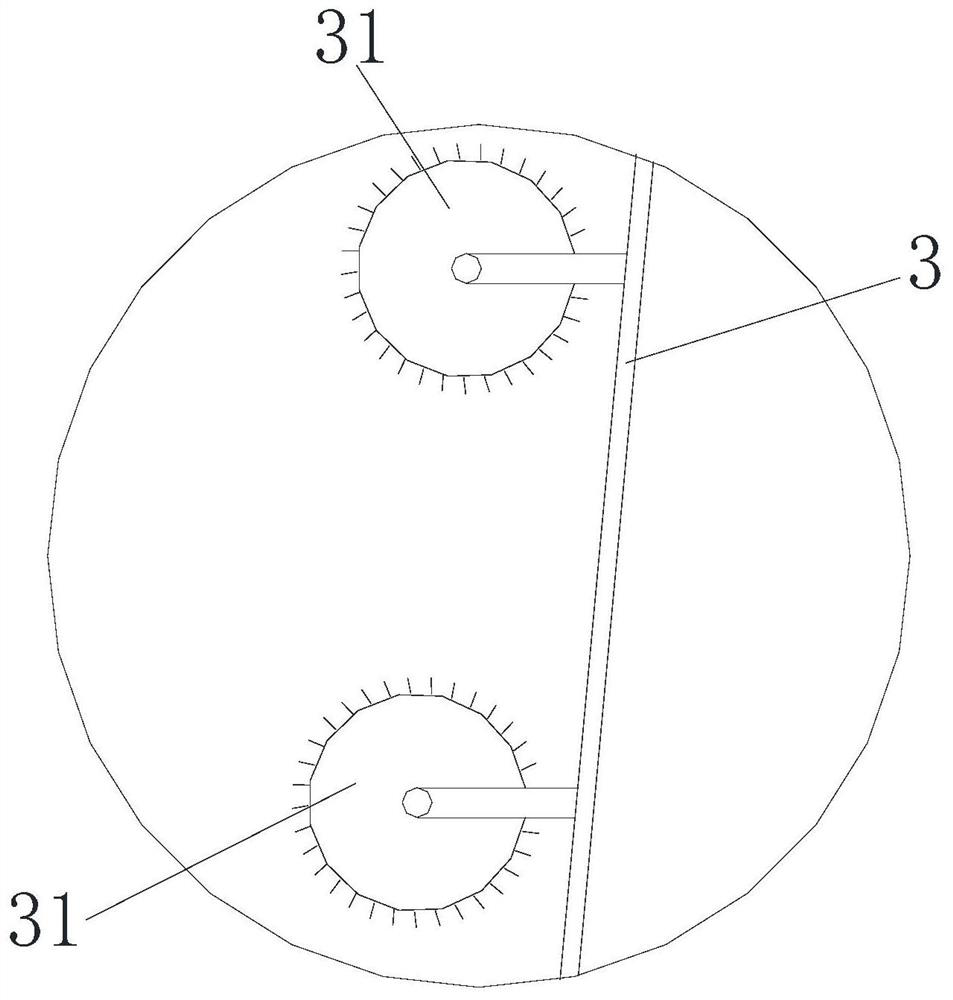

[0048] The fiber obtained in step 3 and step 2 is drawn by air blowing, and the drafting airflow blows the fiber to the guide roller; the guide roller 31 and the drafting airflow clamp the fiber to move downward, and the fiber passes through a plurality of guide rollers to form a wave shape;

[0049] Step 4: The impact water flow impacts the wave-shaped fiber into the formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com