A kind of printing paste and preparation method thereof

A printing color paste, deionized water technology, applied in the field of color paste, to achieve the effect of good fabric fiber affinity, solving color fastness, good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

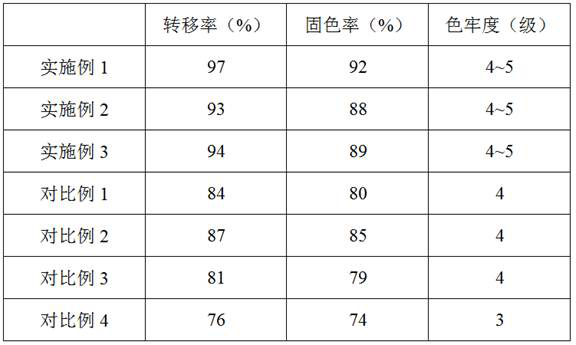

Examples

Embodiment 1

[0035] A printing slurry, wherein the printing pulp is mixed into 32 parts by weight of the bladder fluid into a 32 parts by weight of the bladder liquid;

[0036] The cystic fluid was prepared from the weight of the following material: 8 parts of pigment, 6 copies, 2 parts of thiourea, 1.2 parts of antifoam, 0.5 parts of antifoaming agent, 82.3 parts of deionized water.

[0037] The sacral solution is a polyelectrolyte dispersant.

[0038] The pigment is C.I. Pigment red 112.

[0039] The paste is composed of seafubbles, hydrolyzed small nucleus, according to weight ratio 1: 0.4.

[0040] The preparation method of the polyelectrolyte dispersant is:

[0041] S11, 100 parts by weight of deionized water, 0.9 parts by weight of sodium hydrogen sulfite, 0.9 parts by weight of isopropanol, stirred well, to obtain a first mixture;

[0042] S12, ammonium sulfate, deionized water is compounded by weight ratio of 1:35 to give an aqueous ammonium sulfate solution;

[0043] S13, the first mi...

Embodiment 2

[0050] A printing slurry, wherein the printing pulp is mixed into 32 parts by weight of the bladder fluid into a 32 parts by weight of the bladder liquid;

[0051]The cystic fluid is prepared from the weight of the following material: 2 parts of pigment, 2 parts of paste, 1 part of thiourea, 0.5 defoaming agent, 70 deionized water;

[0052] The sacral solution is a polyelectrolyte dispersant.

[0053] The pigment is C.I. Pigment red 112.

[0054] The paste is composed of seafubbles, hydrolyzed small nucleus, according to weight ratio 1: 0.4.

[0055] The preparation method of the polyelectrolyte dispersant is:

[0056] S11, 100 parts by weight of deionized water, 0.9 parts by weight of sodium hydrogen sulfite, 0.9 parts by weight of isopropanol, stirred well, to obtain a first mixture;

[0057] S12, ammonium sulfate, deionized water is compounded by weight ratio of 1:35 to give an aqueous ammonium sulfate solution;

[0058] S13, the first mixture was added to the four flask, addin...

Embodiment 3

[0065] A printing slurry, wherein the printing pulp is mixed into 32 parts by weight of the bladder fluid into a 32 parts by weight of the bladder liquid;

[0066] The cystic fluid is prepared from the weight of the following material: 5 parts of pigment, 4 copies of paste, 1.2 parts of thiourea, 0.8 parts of anti-dyeing salt, 0.6 parts of antifoaming agent, 85 parts of deionized water;

[0067] The sacral solution is a polyelectrolyte dispersant.

[0068] The pigment is C.I. Pigment red 112.

[0069] The paste is composed of seafubbles, hydrolyzed small nucleus, according to weight ratio 1: 0.4.

[0070] The preparation method of the polyelectrolyte dispersant is:

[0071] S11, 100 parts by weight of deionized water, 0.9 parts by weight of sodium hydrogen sulfite, 0.9 parts by weight of isopropanol, stirred well, to obtain a first mixture;

[0072] S12, ammonium sulfate, deionized water is compounded by weight ratio of 1:35 to give an aqueous ammonium sulfate solution;

[0073] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com