Firework tube feeding mechanism

A technology of firecrackers and pressure cylinders, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of high labor dependence, complicated production process, high cost, etc., and achieve the effect of clean working environment, low labor cost and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

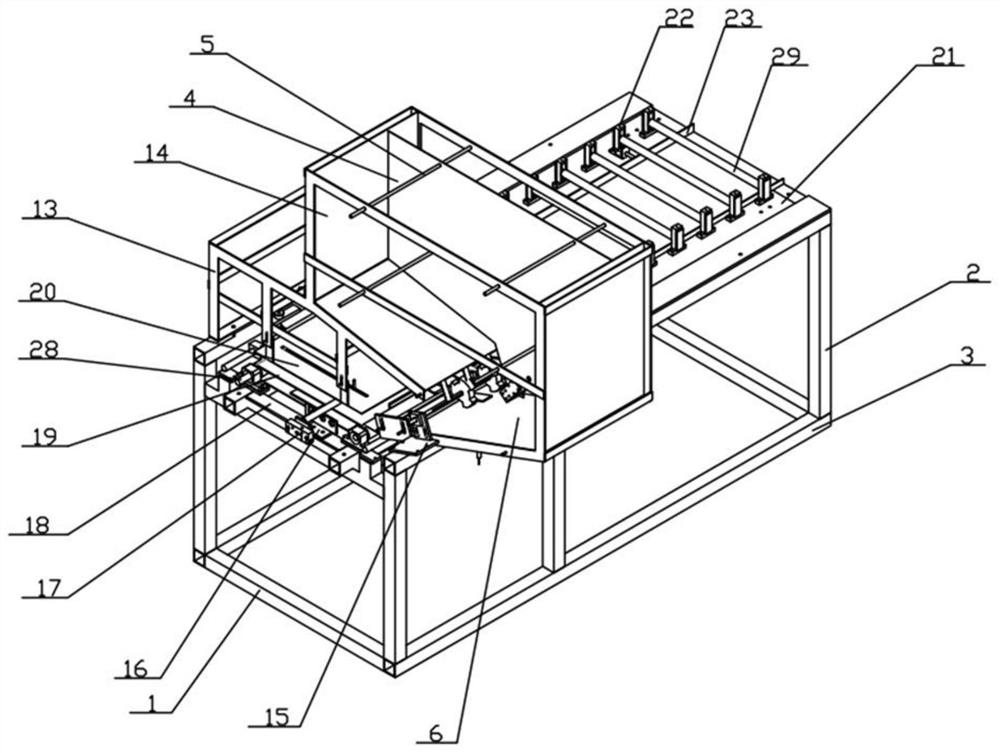

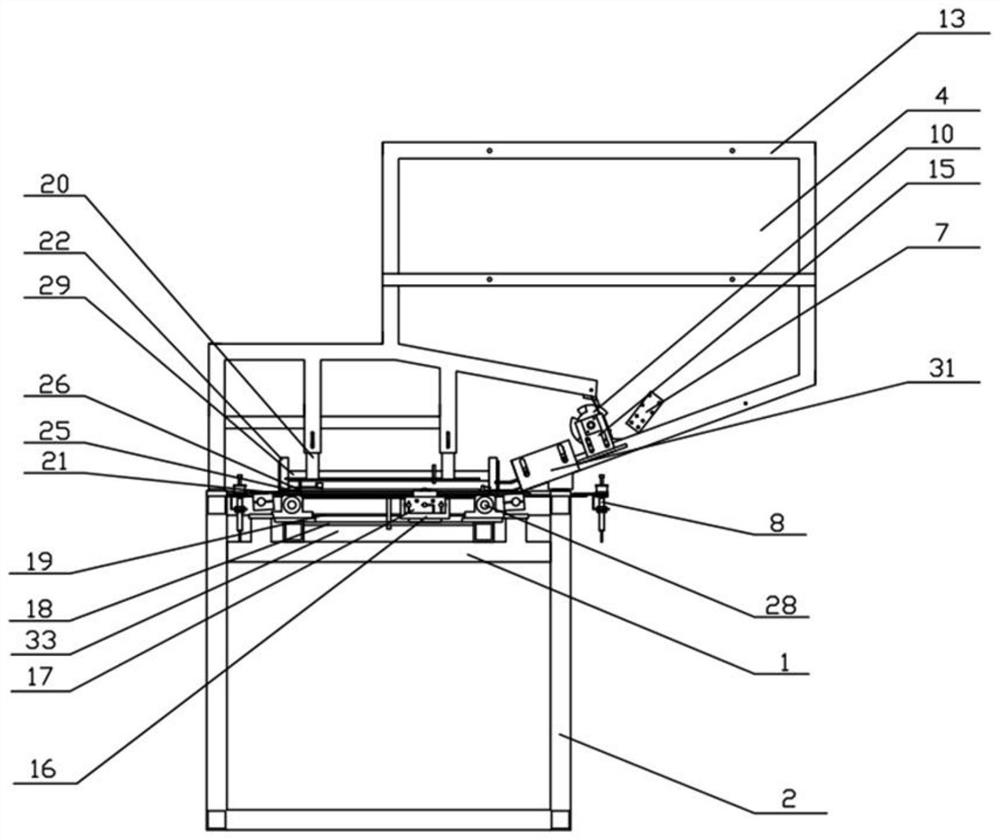

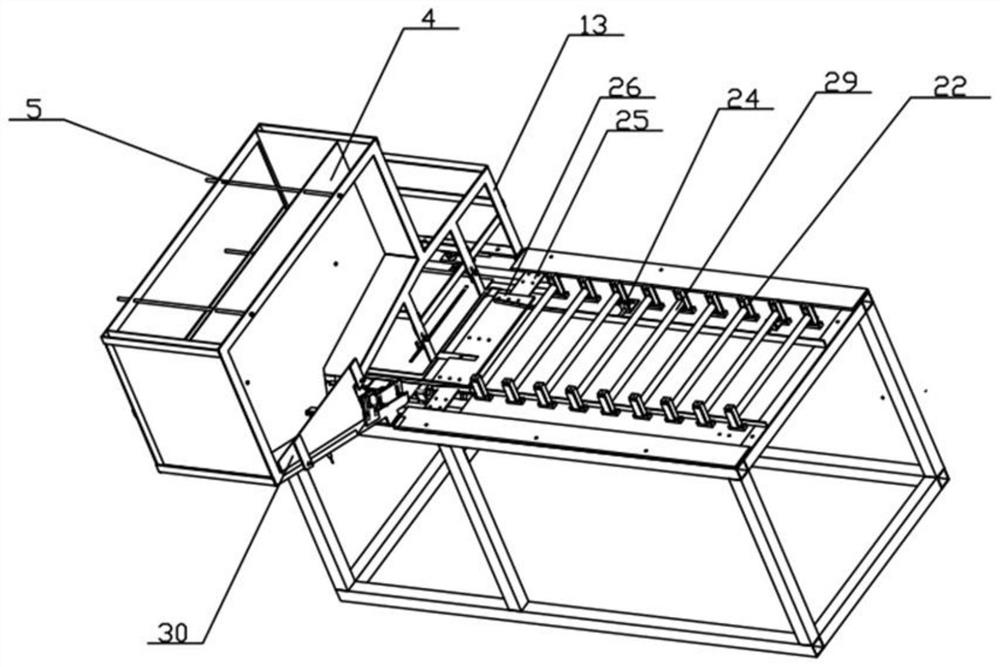

[0021] like Figure 1 to Figure 7 As shown, a kind of firecracker tube feeding mechanism of the present invention adopts the technical scheme that the main frame is a cuboid frame structure welded by the horizontal bar 1, the vertical bar 2, and the vertical bar 3, and the upper surface of one end of the main frame is fixedly connected with a The main board 21 has an underframe 33 fixedly installed on the upper surface of the other end. The underframe 33 is fixedly connected by a base plate 18 and a conveyor belt 19 is installed on it. The two ends of the conveyor belt 19 are respectively rotated and installed with a conveyor belt drive shaft 28. The conveyor belt drive shaft 28 will The conveyor belt 19 is tensioned and connected with a motor, and the motor drives the conveyor belt drive shaft 28 to rotate, so that the conveyor belt 19 rotates to realize the transmission. The two sides of the main board 21 are evenly spaced and fixedly connected with the pressure cylinder brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com