Treatment method and system for xylene oxidation reaction liquid

A technology of oxidation reaction and xylene, applied in the direction of chemical instruments and methods, separation methods, separation/purification of carboxylic acid compounds, etc., can solve the problems of increased energy consumption, high loss of peroxidation impurities, unsatisfactory, etc., to avoid safety The effects of eliminating hidden dangers, improving product yield, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

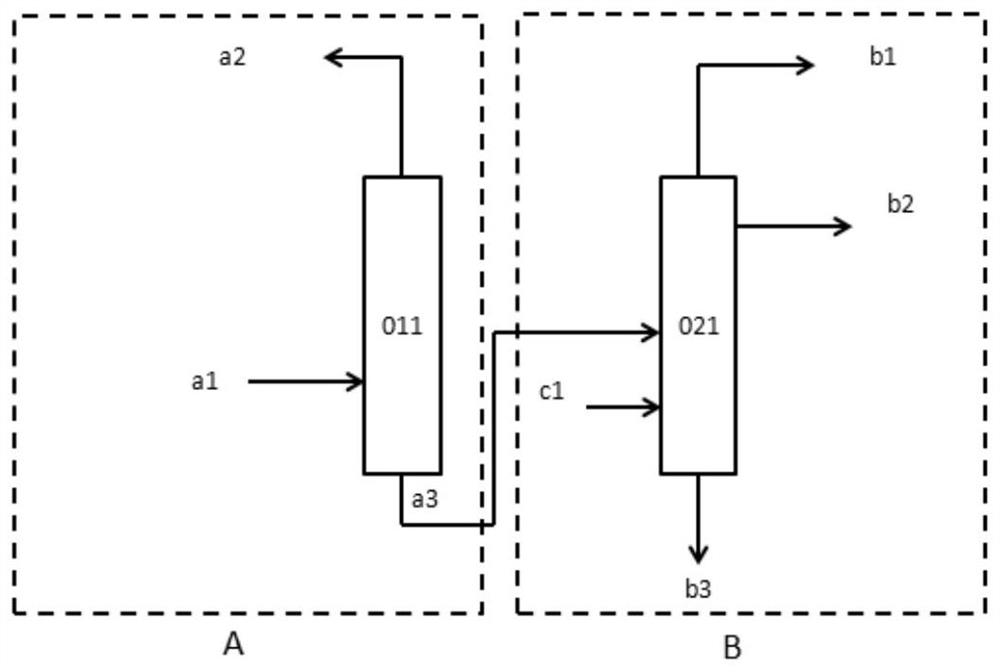

Embodiment 1

[0187] In this embodiment, the above-mentioned oxidation reaction liquid 1 of m-xylene is processed, and the oxidation reaction liquid 1 of m-xylene is transported to a light-removing system through a transfer pump, and is preheated by a preheater and then enters into a rectifying tower for decompression purification Distillation, under the conditions of pressure of 3.5kPa and tower kettle temperature of 176°C, m-xylene, m-tolyl benzaldehyde, m-tolyl benzyl alcohol and other components in the oxidation reaction liquid are vaporized and enriched to the top of the tower, and then passed through the condenser. After condensation, it is collected in the light component collection tank for temporary storage, and then transported to the oxidation section of the previous m-xylene through the transfer pump, and the enriched to the bottom of the tower contains m-toluic acid, isophthalic acid, m-carboxybenzaldehyde The delight mother liquor with equal components is continuously transport...

Embodiment 2

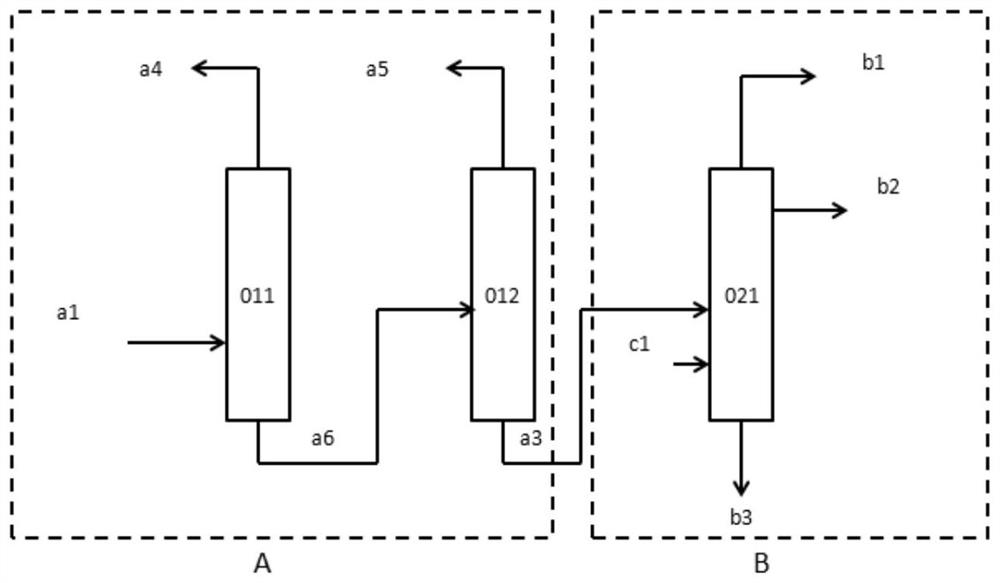

[0190] In this example, the oxidation reaction solution 1 of the above-mentioned m-xylene is treated, and the delighting treatment of the oxidation reaction solution is the same as that in Example 1. The difference from Example 1 is that the deweighting system in this example includes two refined Distillation tower, after delighting treatment, the delighting mother liquor containing benzoic acid, m-toluic acid, isophthalic acid, m-carboxybenzaldehyde and other components is extracted from the bottom of the rectifying tower, and is continuously transported to the deweighting system by a transfer pump In the first rectifying tower, and pass into diethyl isophthalate in the middle and lower part of the first rectifying tower, under the condition of pressure 3.5kPa, tower still temperature 182.7 ℃, underpressure rectification, at the top of the tower, The impurity benzoic acid is discharged, and the bottom liquid enters the second rectifying tower and continues vacuum rectification...

Embodiment 3

[0193] In the present embodiment, the oxidation reaction solution 2 of the above-mentioned o-xylene is processed, and the oxidation reaction solution is transported to the first delighting unit of the delighting system by a transfer pump, and is preheated by a preheater and then enters into a distillation kettle for decompression. Distillation, under the conditions of 30kPa and 130.2℃, the o-xylene in the oxidation reaction solution is vaporized and enriched to the top of the kettle, and then condensed by the condenser and collected into the light component collection tank for temporary storage, and then transported to the front by the transfer pump. In the oxidation section of ortho-xylene, the first delighting mother liquor enriched to the bottom of the still enters the rectification column of the second delighting unit, under the conditions of pressure 3.5kPa and column still temperature 176.7℃, rectification under reduced pressure, and the top of the column is rectified unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com