Preparation method of Bi3O4Br/CsPbBr3 composite material

A composite material, 3·5H2O technology, applied in separation methods, chemical instruments and methods, carbon monoxide, etc., can solve problems such as insufficient performance, good catalytic performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

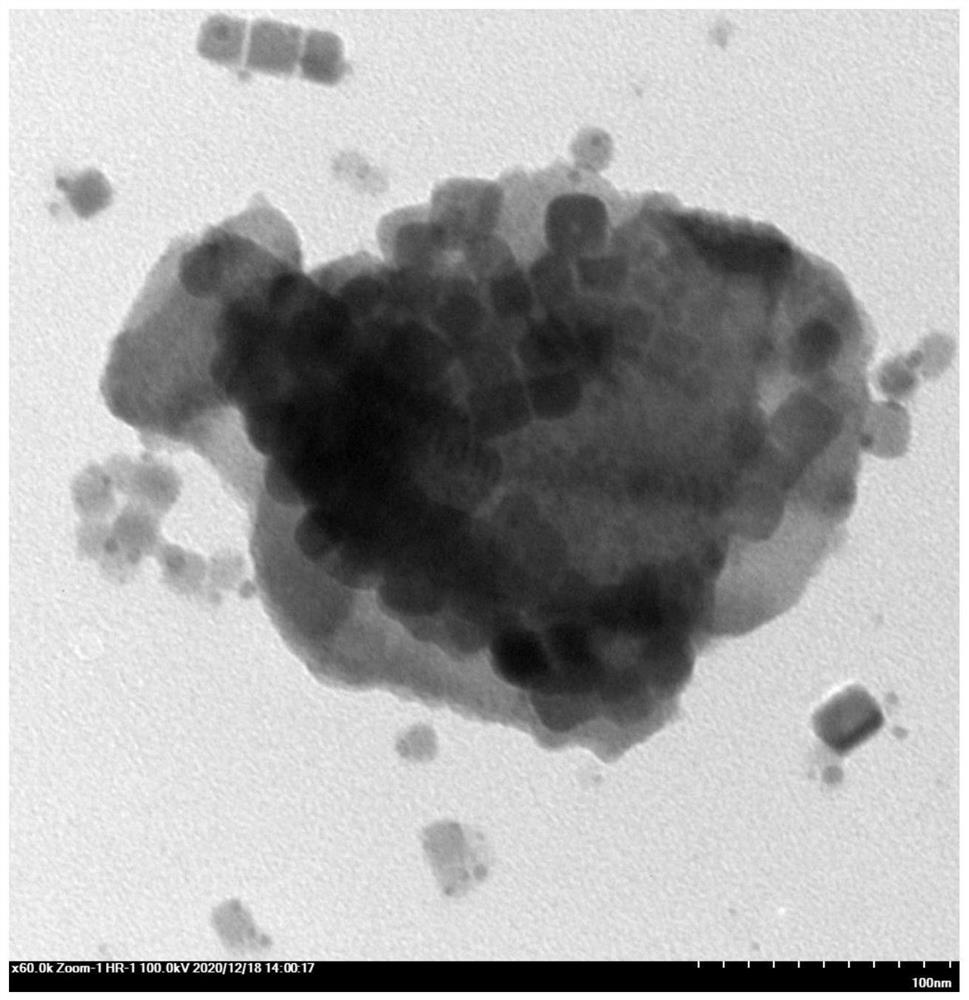

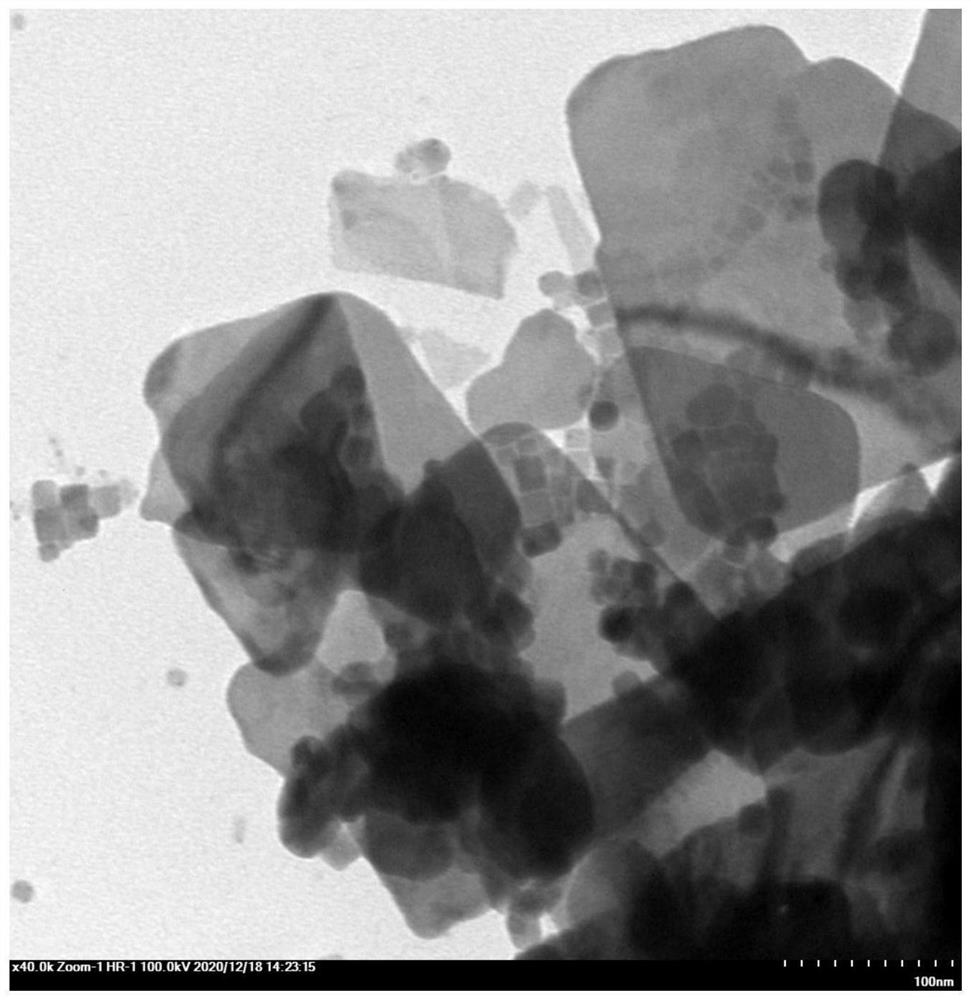

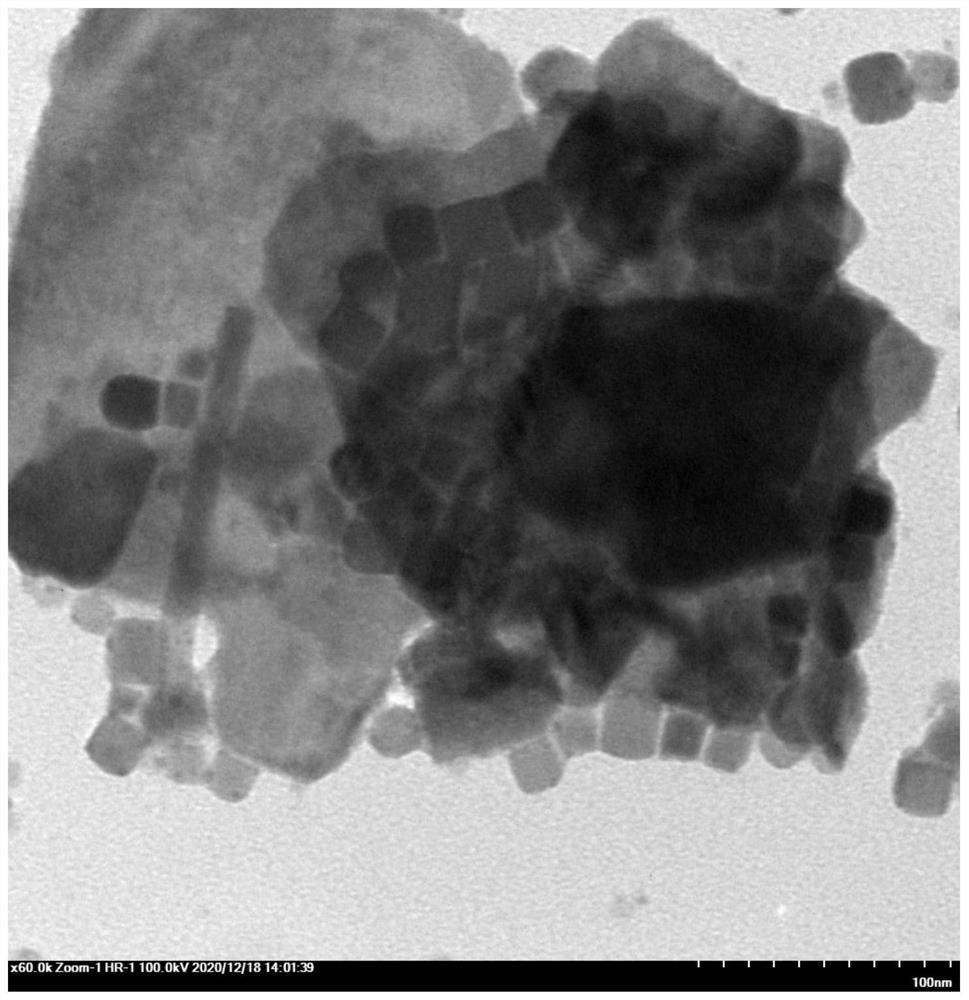

Image

Examples

Embodiment 1

[0025] A Bi 3 o 4 Br / CsPbBr 3 The preparation method of composite material, comprises the following steps:

[0026] (1) Preparation of Bi 3 o 4 Br nanosheets: 2mmol of Bi(NO 3 ) 3 ·5H 2 Dissolve O in 10 mL of ethylene glycol to form solution 1, dissolve 2 mmol of KBr in 10 mL of water to form solution 2, add solution 2 to solution 1 at a stirring speed of 200 rpm, and then add 5 mL of ammonia water to form a white suspension . The white suspension was reacted in a 50mL autoclave at 160°C for 12h to obtain Solution 3; Wash Solution 3 with deionized water and absolute ethanol three times each, centrifuge at 5000rpm for 5min to collect the precipitate, and dry it in vacuum at 60°C for 12h get Bi 3 o 4 Br nanosheets.

[0027](2) Preparation of cesium oleate reaction precursor: 2.5mmol CsCO 3 and 2.5mL oleic acid were added to a flask containing 40mL octadecene, and N 2 Protected, heated in an oil bath at 120°C for 1 hour, raised the temperature to 150°C within 0.5 hou...

Embodiment 2

[0031] A Bi 3 o 4 Br / CsPbBr 3 The preparation method of composite material, comprises the following steps:

[0032] (1) Preparation of Bi 3 o 4 Br nanosheets: 2mmol of Bi(NO 3 ) 3 ·5H 2 Dissolve O in 10 mL of ethylene glycol to form solution 1, dissolve 2 mmol of KBr in 10 mL of water to form solution 2, add solution 2 to solution 1 at a stirring speed of 200 rpm, and then add 5 mL of ammonia water to form a white suspension . The white suspension was reacted in a 50mL autoclave at 160°C for 12h to obtain Solution 3; Wash Solution 3 with deionized water and absolute ethanol three times each, centrifuge at 5000rpm for 5min to collect the precipitate, and dry it in vacuum at 60°C for 12h get Bi 3 o 4 Br nanosheets.

[0033] (2) Preparation of cesium oleate reaction precursor: 2.5mmol CsCO 3 and 2.5mL oleic acid were added to a flask containing 40mL octadecene, and N 2 Protected, heated in an oil bath at 120°C for 1 hour, raised the temperature to 150°C within 0.5 ho...

Embodiment 3

[0037] A Bi 3 o 4 Br / CsPbBr 3 The preparation method of composite material, comprises the following steps:

[0038] (1) Preparation of Bi 3 o 4 Br nanosheets: 2mmol of Bi(NO 3 ) 3 ·5H 2 Dissolve O in 10 mL of ethylene glycol to form solution 1, dissolve 2 mmol of KBr in 10 mL of water to form solution 2, add solution 2 to solution 1 at a stirring speed of 200 rpm, and then add 5 mL of ammonia water to form a white suspension . The white suspension was reacted in a 50mL autoclave at 160°C for 12h to obtain Solution 3; Wash Solution 3 with deionized water and absolute ethanol three times each, centrifuge at 5000rpm for 5min to collect the precipitate, and dry it in vacuum at 60°C for 12h get Bi 3 o 4 Br nanosheets.

[0039] (2) Preparation of cesium oleate reaction precursor: 2.5mmol CsCO 3 and 2.5mL oleic acid were added to a flask containing 40mL octadecene, and N 2 Protected, heated in an oil bath at 120°C for 1 hour, raised the temperature to 150°C within 0.5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com