Multi-material photocuring 3D printing equipment

A 3D printing and light-curing technology, applied in the field of 3D printing, can solve the problems of limiting the types of 3D printing materials, easy cross-contamination of 3D printing materials, and limiting the forming size, etc., to improve the precision and quality of light-curing forming, and avoid interlayer Effect of poor binding and mechanical mismatch, avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

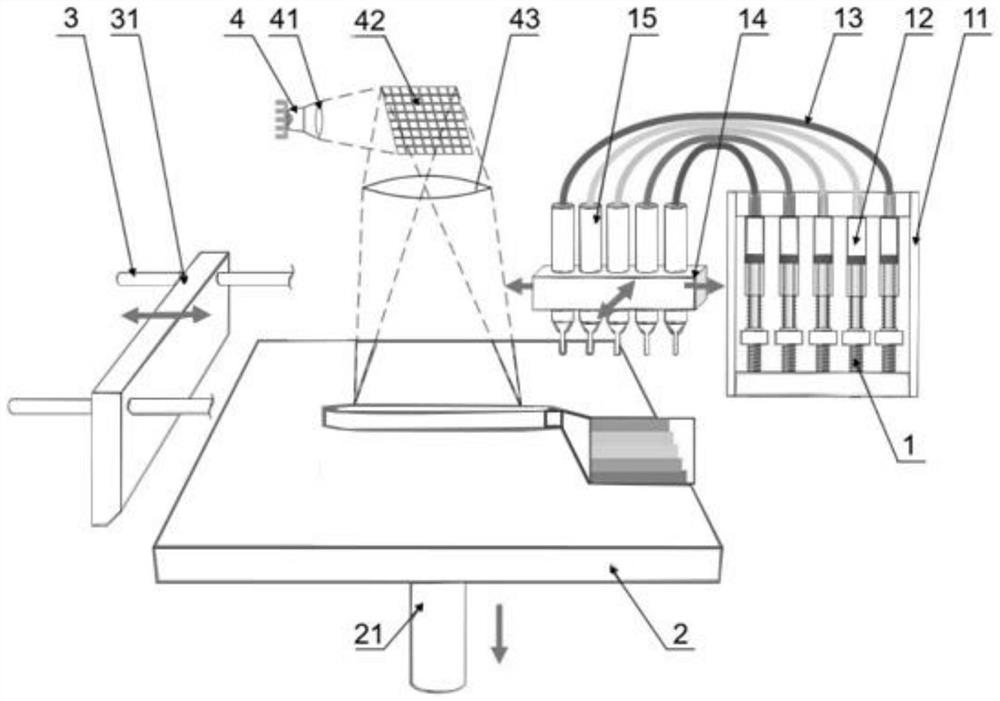

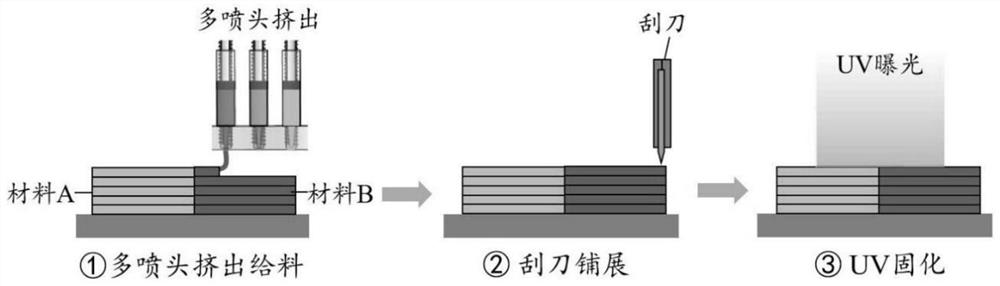

[0037] Such as figure 2As shown, in the embodiment of the present invention, different types of materials can be coated on a two-dimensional plane through the integrated nozzle extrusion mechanism, and the extruded material (low-viscosity slurry or high-viscosity paste material) can be evenly moistened by the scraper 31. Wet spreading, and then adjusting the UV curing parameters to obtain a matching light curing effect, so that multiple materials in the two-dimensional plane can be cross-linked and cured at the same time, and a multi-material part blank with high mechanical stability can be formed in one piece. The invention can coat a variety of UV curable materials (including polymers, ceramics, metals and composite materials) in a two-dimensional plane, and can form super-large multi-material parts (the size of the formed part depends on the size of the forming platform).

Embodiment 2

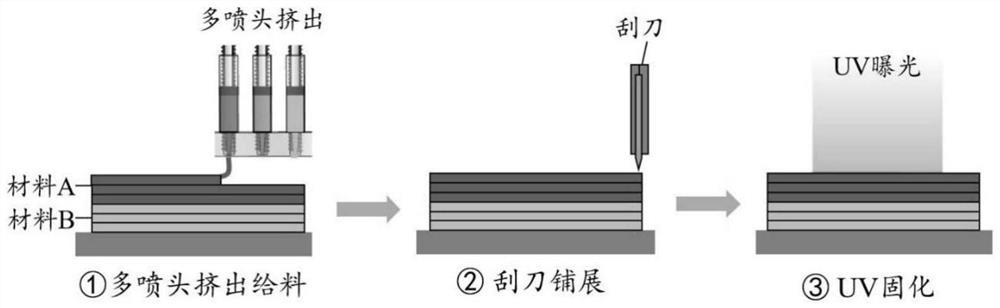

[0039] Such as image 3 As shown, the embodiment of the present invention can achieve interlayer coating of different types of materials through the integrated nozzle extrusion mechanism, and the extruded material (low-viscosity slurry or high-viscosity paste material) can be evenly wetted and spread by the scraper 31 , and then optimize the light curing effect by real-time adjustment of UV light source parameters to enhance the interface bonding performance between layers of heterogeneous materials, and form a multi-material part green body with high interface bonding performance in an integrated manner. The invention can realize the overall manufacturing of homogeneous and heterogeneous gradient material parts compounded by various materials such as polymer, ceramic, metal and composite materials thereof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com