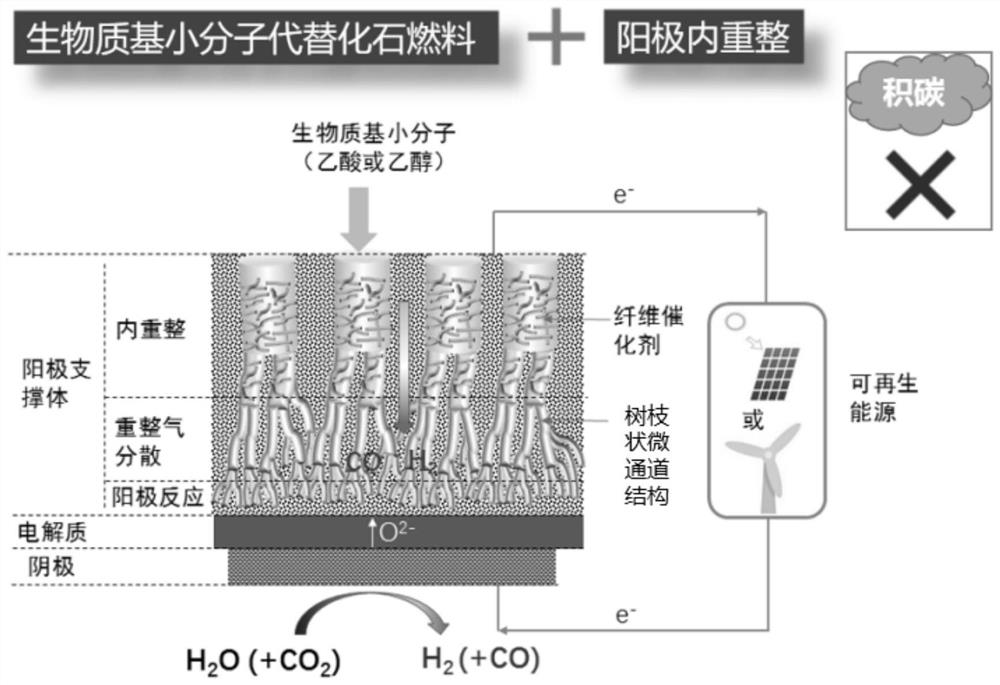

Novel renewable energy storage reactor and application thereof

A renewable energy and reactor technology, applied in the direction of energy input, electrolysis components, electrodes, etc., can solve the problem of not being able to fundamentally solve the dependence of fossil energy, and achieve the effect of improving the ability to resist carbon deposition and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

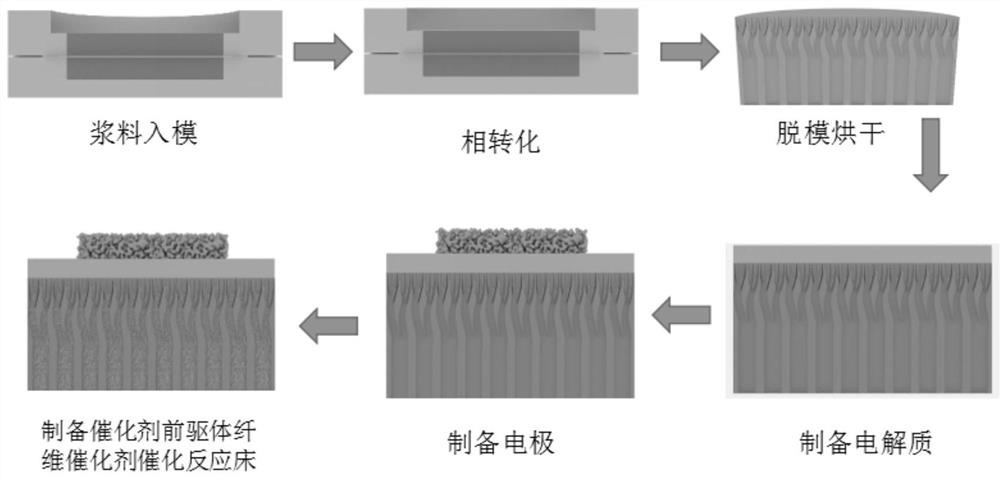

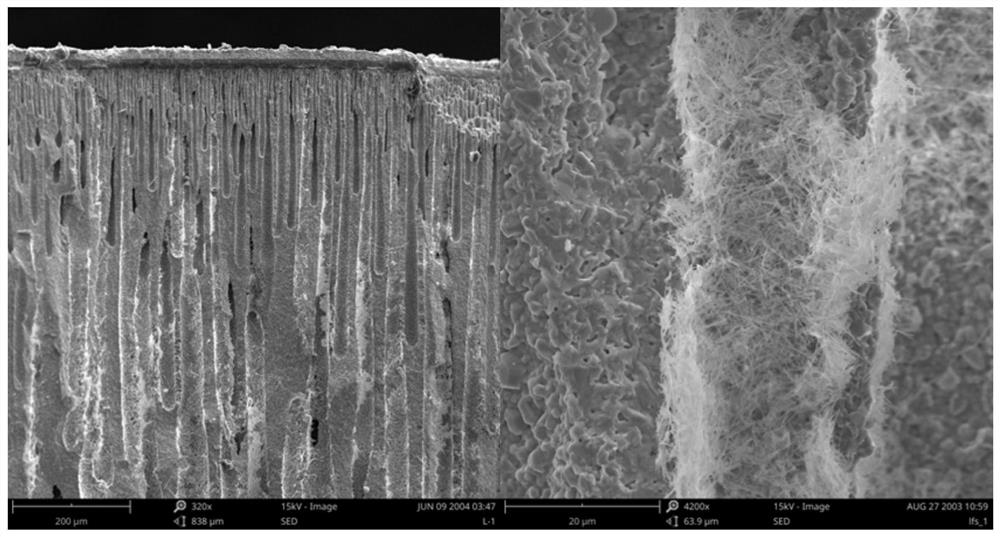

Embodiment 1

[0042] 36.99 gNiO, 24.66 g (Y 2 o 3 ) 0.08 Zr 0.92 o 2 The powder, 4.3 g of polyethersulfone, 24 g of N-methylpyrrolidone and 0.43 g of polyvinylpyrrolidone were weighed and placed in a ball mill jar, and milled for 48 hours using a planetary ball mill to form a premixed material. The premixed slurry was filtered out and placed in a vacuum stirring device for stirring and exhausting treatment. The vacuum degree was set at -0.08~-0.1MPa, and the stirring and exhausting treatment was performed for 20 minutes to obtain a uniformly mixed electrode slurry without air bubbles. Pour the slurry into the lower mold, place a stainless steel screen with a sieve of 70 μm on the surface of the slurry and allow the slurry to slightly pass through the stainless steel screen, then press the upper mold with upper and lower ends on the screen, and Inject 10mm~15mm thick slurry. Water was used as a flocculant and poured from the top of the slurry to initiate the phase inversion process. Af...

Embodiment 2

[0053] The preparation process of the full battery is the same as the process 2 of Example 1. The full battery is prepared by co-sintering the electrode and the electrolyte, and the electrochemical oxidation of pure ethanol is used to assist in the electrolysis of water.

[0054] Preparation of catalyst for electrolysis of water assisted by electrochemical oxidation of ethanol:

[0055] PD-Gd 0.1 Ce 0.9 o 2 Catalyst precursor: Weigh 0.0444 g Gd(NO 3 ) 3 ·6H 2 O (≥99%), 0.3936 gCe(NO 3 ) 3 ·6H 2 O (≥99%), 4.72 g of N,N-dimethylformamide, and 0.102 g of polyvinylpyrrolidone (PVP, molecular weight 1,300,000) were placed in a beaker and fully dissolved. Weigh 0.0533 g Pd(NO 3 ) 3 2H 2 O (≥99%), dissolved in 1 g of the prepared solution. Then dipped into the support electrode microchannel, sintered at 750 for 2 hours, repeated 2 times.

[0056] Ru-Gd 0.1 Ce 0.9 o 2 Fiber catalyst: Weigh 0.3173 g Gd(NO 3 ) 3 ·6H 2 O (≥99%), 0.1313 gRuCl 3 , 2.7475 g Ce(NO 3 ) 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com