Preparation method of antibacterial and self-cleaning cotton fabric

A cotton fabric, self-cleaning technology, applied in the field of cotton fabrics, can solve the problems of reducing the comfort of cotton fabrics, moldy, difficult to clean, etc., and achieve the effect of enhancing self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

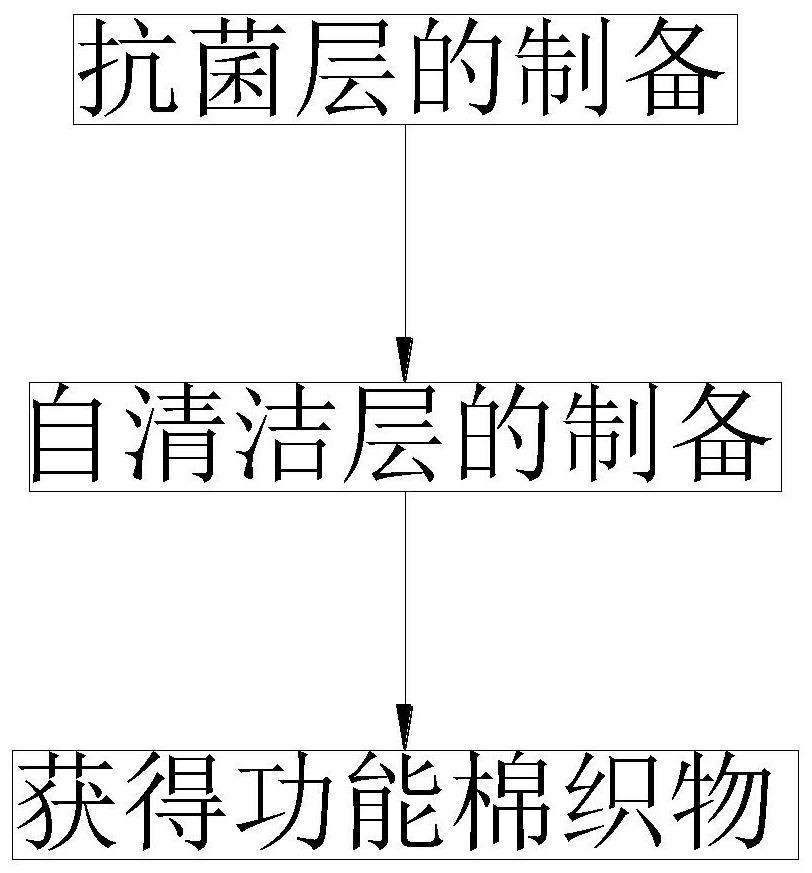

[0028] A kind of preparation method with antibacterial and self-cleaning cotton fabric, comprises the following steps:

[0029] S1. The preparation of the antibacterial layer, at first coating the upper and lower sides of the bamboo fiber cloth with nano-silver sol, and then drying the bamboo fiber cloth coated with nano-silver sol, so that the nano-silver sol can be combined with the bamboo fiber cloth. Fiber fabrics are combined to obtain an antibacterial layer, and then the antibacterial layer is thermally bonded to the cotton fabric;

[0030] S2. The preparation of the self-cleaning layer, which changes the surface structure of the cotton fabric through bionics to form a microemulsion protruding surface "lotus leaf structure", thereby endowing the textile with an excellent water and oil repellent effect; at the same time, on the surface of the cotton fabric Adhering to photocatalysts with photocatalytic ability, such as titanium dioxide and zinc oxide, can release electron...

Embodiment 2

[0042] A kind of preparation method with antibacterial and self-cleaning cotton fabric, comprises the following steps:

[0043] S1. The preparation of the antibacterial layer, at first coating the upper and lower sides of the bamboo fiber cloth with nano-silver sol, and then drying the bamboo fiber cloth coated with nano-silver sol, so that the nano-silver sol can be combined with the bamboo fiber cloth. Fiber fabrics are combined to obtain an antibacterial layer, and then the antibacterial layer is thermally bonded to the cotton fabric;

[0044] S2. The preparation of the self-cleaning layer, which changes the surface structure of the cotton fabric through bionics to form a microemulsion protruding surface "lotus leaf structure", thereby endowing the textile with an excellent water and oil repellent effect; at the same time, on the surface of the cotton fabric Adhering to photocatalysts with photocatalytic ability, such as titanium dioxide and zinc oxide, can release electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com