Efficient multi-nozzle polyether polyol preparation device and process

A technology for polyether polyols and preparation devices, which is applied in the direction of feeding devices, chemical/physical/physical-chemical fixed reactors, chemical instruments and methods, etc., and can solve the problem of increasing control nodes, uneven molecular division, and inability to Problems such as the production of high molecular weight products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

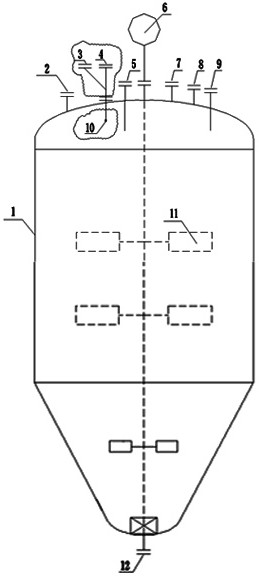

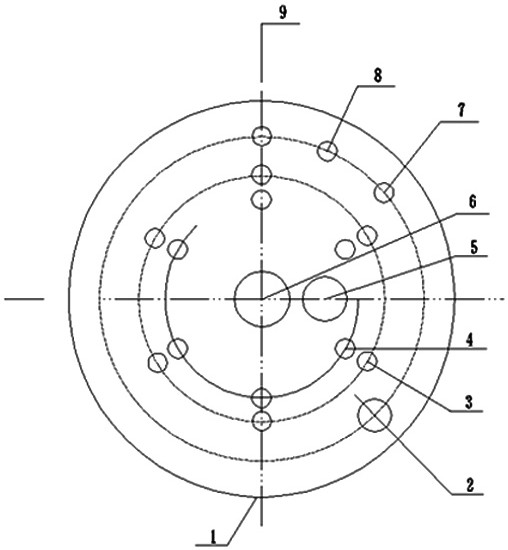

[0026] see figure 1 , a high-efficiency multi-nozzle polyether polyol preparation device and process of the present invention includes a reactor cylinder 1, a prepolymer inlet 2, an alkoxide inlet pipe 3, a reaction liquid spiral mixing inlet pipe 4, and a manhole 5 , Agitator motor 6, safety valve port 7, vacuum outlet 8, nitrogen inlet 9, atomizing nozzle 10, agitator blade 11, material outlet 12.

[0027] The specific structure is as follows:

[0028] Prepolymer inlet 2, alkoxide inlet pipe 3, reaction solution spiral mixing inlet pipe 4, manhole 5, safety valve port 7, vacuum outlet 8, nitrogen inlet 9 are welded to the upper head part of the reactor cylinder 1

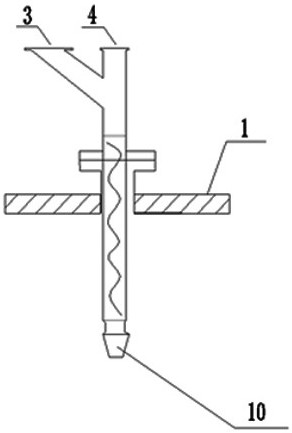

[0029] The atomizing nozzle 10 is connected to the lower end of the reaction solution spiral mixing inlet pipe 4, that is, it is arranged inside the reaction cylinder 1;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com