Photocuring 3D printing manufacturing method of integral SiC-based microreactor

A microreactor, 3D printing technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical fixed reactors, etc., can solve the problem of poor welding strength between the carrier and the substrate, contact Problems such as large thermal resistance and cross-gas, achieve the effects of shortening research and development costs, high load strength, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

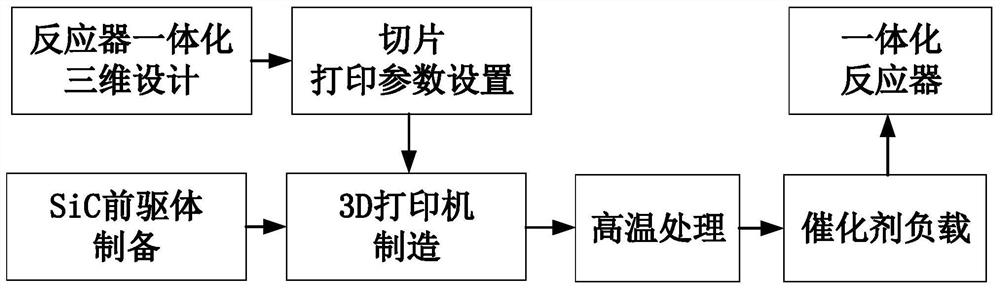

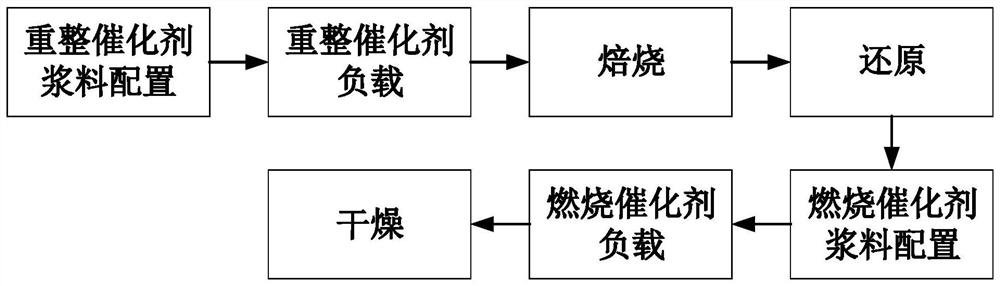

Method used

Image

Examples

Embodiment

[0079] (1) Configure precursor slurry, polycarbosilane 50wt.%, photocurable resin PEGDA47wt.%, photoinitiator TPO-L2.75wt.%, dispersant 0.05wt.%, defoamer 0.2wt.%. Use a speed-regulating precision mixer, preferably at 1500rpm to fully stir for about 2 hours, pass through a 200PPI filter and put it into the solidification liquid tank for use;

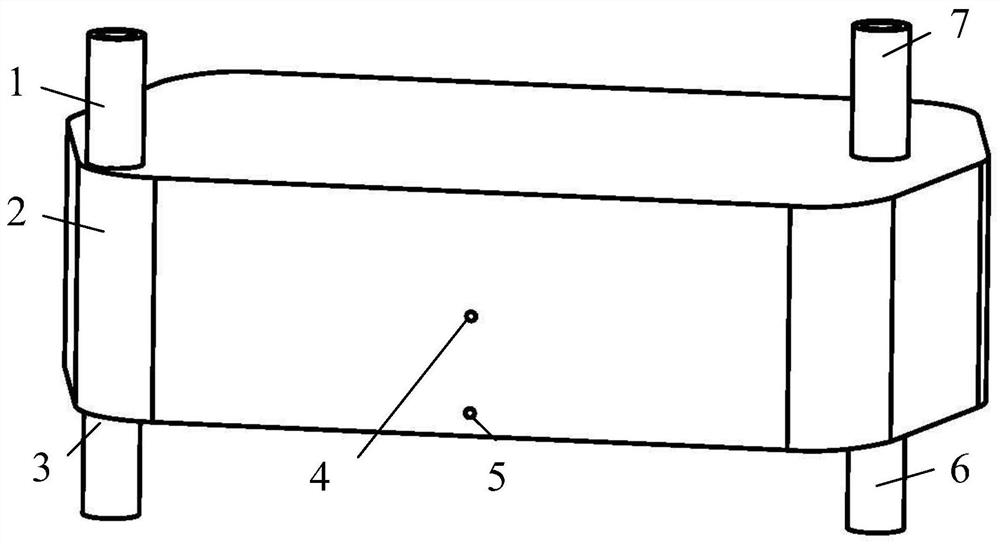

[0080] (2) Using the reactor model designed by SolidWorks, the widths of the first combustion chamber flow channel 12, the first reforming chamber flow channel 13, the second combustion chamber flow channel 14, and the second reforming chamber flow channel 15 are all set to 1mm. The depth is set to 0.5mm, and the data is exported to the DLP photocuring 3D printer. The printing parameters: the exposure time of the bottom layer is 60s, the exposure time of the upper layer is 10s, and the light intensity is 100mW / cm 2 , printing speed 20mm / h, such as Figure 8 Cured and molded as shown.

[0081] (3) Put the precursor solidification model ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com