A kind of silicone rubber and its production process

A silicone rubber and product technology, applied in the field of silicone rubber and its production process, can solve problems such as the viscosity cannot meet the demand, achieve the effect of increasing viscosity, ensuring purity and viscosity, and enhancing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A kind of production technique of silicone rubber, its each component weight is as described in table 1, comprises the following steps:

[0061] S1, first weigh tetramethylammonium hydroxide and the catalyst by weight, add them to the reaction vessel, then feed 80ml of cooling water, and adjust the nitrogen flow to 1.0m 3 / s, vacuum pressure -45kPa, open the glass reactor, put the reaction vessel into it, heat it to 70±2°C, and react for 30min to obtain the catalytic precursor;

[0062] The refractive index of tetramethyldivinyldisiloxane (n D 20 ) is 1.400-1.413, specific gravity (d 4 20 ) is 0.800-0.830g / cm 3 ; The catalyst is composed of sodium trimethylsiliconate, tetramethyltetravinylcyclotetrasiloxane and hexamethylcyclotrisiloxane in a weight ratio of 1:1:0.2.

[0063] S2. After weighing the octamethylcyclotetrasiloxane and the cross-linking agent by weight, add them to the reaction vessel in S1, turn on the mixer, control the rotation speed to be 120r / min a...

Embodiment 2-6

[0072] A production process of silicone rubber is different from Example 1 in that each component and its corresponding weight are shown in Table 1.

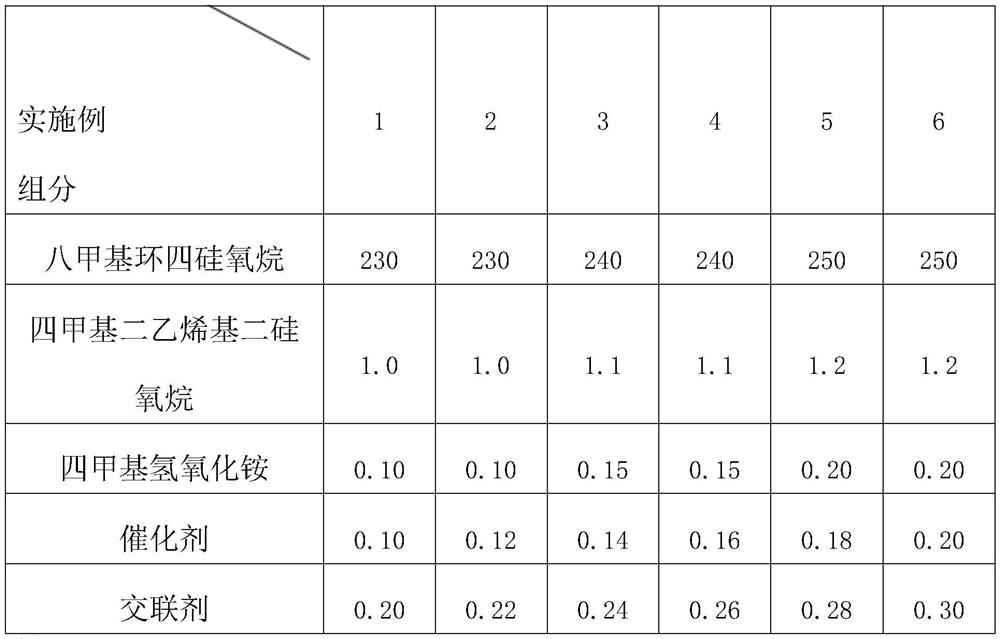

[0073] Each component and its corresponding weight (g) in the embodiment 1-6 of table 1

[0074]

Embodiment 7

[0076] A production process of silicone rubber, the difference from Example 1 is that the specific steps of S1 are as follows, first weigh tetramethyl ammonium hydroxide and catalyst by weight, add them to the reaction vessel, and then feed 70ml of cooling water , adjust the nitrogen flow to 0.5m 3 / s, the vacuum pressure is -35kPa, the glass reactor is opened, the reaction vessel is put in, heated to 70±2°C, and reacted for 15min to obtain the catalytic precursor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com