Composition of hydrogen peroxide catalyst and application thereof

A technology of composition and catalyst, which is applied in the direction of dyeing, textiles and papermaking, etc., can solve the problems of destroying the strength of cotton fiber or spandex fiber, easy yellowing of denim, and long time required, so as to improve strength and elasticity, improve Production environment, the effect of improving color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

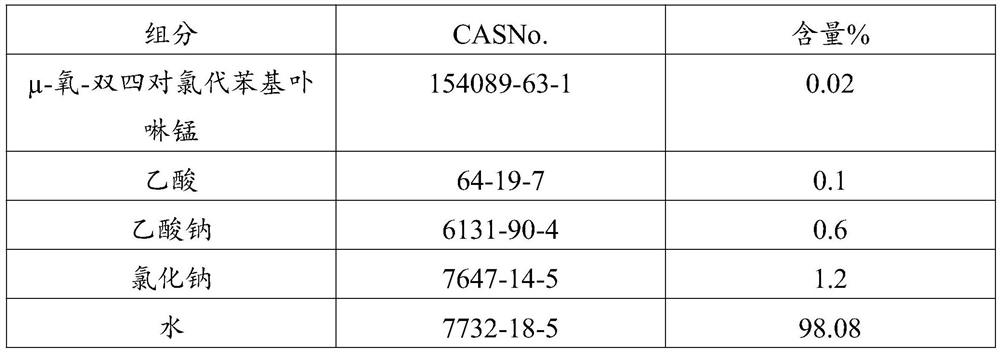

[0023] The manganese inorganic substance is μ-oxygen-bis-tetrachlorophenyl porphyrin manganese, the content of the μ-oxygen-bis-tetrachlorophenyl porphyrin manganese is 0.02%, and the content of the acetic acid is 0.1%, the content of the sodium acetate is 0.6%, the content of the sodium chloride is 1.2%, and the content of the water is 98.08%. Prepared by mixing and stirring.

[0024]

Embodiment 2

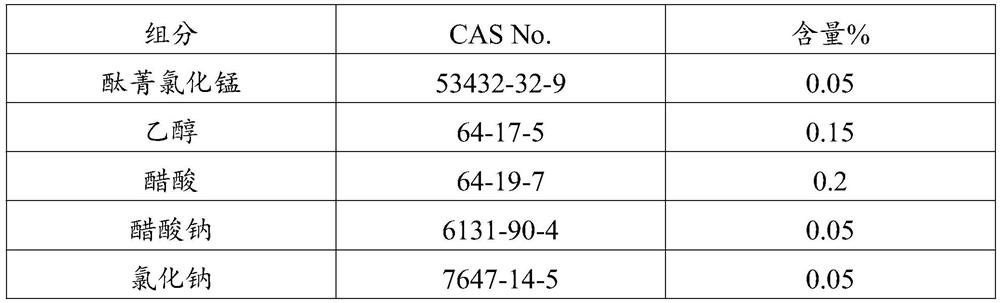

[0026] Ethanol is also included, and the manganese-based inorganic substance is manganese phthalocyanine chloride.

[0027] Preferably, the content of the phthalocyanine manganese chloride is 0.05%, the content of the ethanol is 0.15%, the content of the acetic acid is 0.2%, the content of the sodium acetate is 0.05%, and the content of the sodium chloride The water content is 0.05%, and the water content is 99.5%. Prepared by mixing and stirring.

[0028]

[0029]

[0030] The embodiment of the present invention also provides an application of the composition as a catalyst for sulfur dye bleaching.

[0031] Under the condition that the composition content of the catalyst is 0.02-0.05%, hydrogen peroxide can be greatly catalyzed and activated, and high-valence active substances can be produced, which can replace bleaching water, and the sulfur dye in blue denim can be uniformly processed in a water bath. Bleaching or stripping.

Embodiment 3

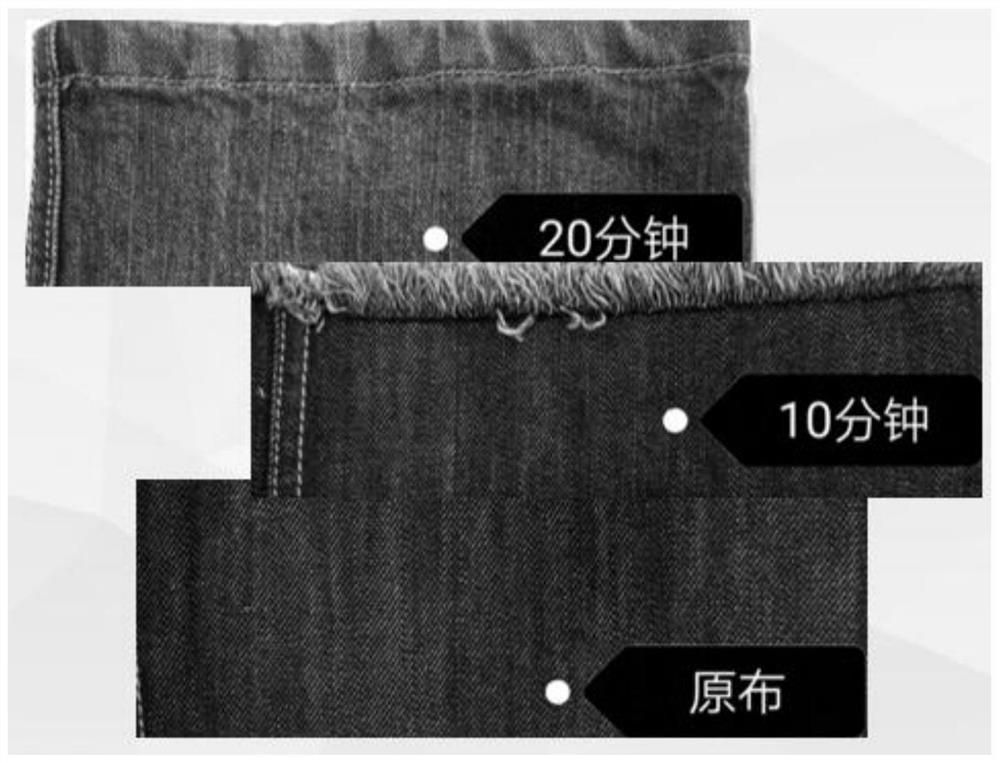

[0033] Bleaching the color of the blue denim fabric comprises the following steps: adding the composition to water at a ratio of 1-5g / L to water; adding sodium hydroxide at a ratio of 1-4g / L to water after five minutes; After two minutes, add hydrogen peroxide with a concentration of 38% according to the ratio of 2-10g / L to water; the reaction temperature is controlled at 45°-55°, and the reaction time is 20-30 minutes.

[0034] The principle of bleaching is: sodium hydroxide is used to adjust the pH value, and the composition becomes a catalyst for hydrogen peroxide to fade the sulfur dyes in blue cattle or black cattle. Under the condition of 50°, 20-30 minutes, the blue or Light black denim.

[0035] Using the hydrogen peroxide catalyst composition as a raw material to bleach the color of blue denim has the following beneficial effects:

[0036] 1. It can replace traditional bleaching water. It can evenly bleach or strip sulfur dyes in a water bath, and improve the color b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com