Ultraviolet positive photoresist based on hexaaryl biimidazole molecular switch and use method

A positive photoresist, molecular switch technology, applied in optics, opto-mechanical equipment, photoplate making process of patterned surface, etc., can solve the problems of high research and development cost, single photoresist structure, difficult to modify, etc. High-rate, light-responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] For oligomer diols that are liquid at room temperature, the preparation method of the corresponding glue A includes the following steps: under light-shielding conditions and an inert gas protection environment, combine a hexaarylbiimidazole molecular switch crosslinking agent with a free radical The organic solution of the quenching agent is mixed with the organic solution of oligomer glycol to obtain glue A. In some embodiments, the organic solvent used in the organic solution is anhydrous ethyl acetate.

[0063] For the oligomer glycol that is solid under normal temperature, the preparation method of its corresponding A glue comprises the steps:

[0064] S1: Under light-shielding conditions and an inert gas protection environment, heat, melt, and dehydrate the oligomer diol at a temperature not higher than 80°C, then add an organic solvent to dissolve and stir, and cool to room temperature for later use;

[0065] S2: Under light-shielding conditions and an inert gas ...

Embodiment 1

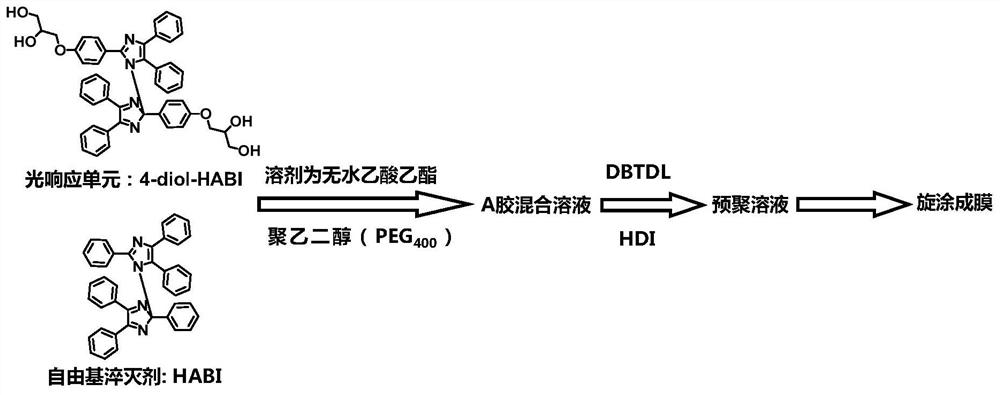

[0076] PTMG with a molecular weight of 1000 1000 It is an oligomer diol, HDI is a diisocyanate, and four-hydroxy functionalized hexaaryl biimidazole crosslinker molecule (4-diol-HABI) is used as a raw material to synthesize a positive-active polyurethane based on a hexaaryl biimidazole molecular switch. photoresist material. The molecular structure of the 4-diol-HABI crosslinking agent is shown in formula (eight).

[0077]

[0078] figure 1 It is a technical roadmap for synthesizing a polyurethane positive photoresist material based on a hexaarylbiimidazole molecular switch using 4-diol-HABI crosslinker molecules as photoresponsive units in Example 1.

[0079] Weigh PTMG 1000 (0.57g; 0.57mmol) was vacuum-dried at 70°C for about 1h until no bubbles were generated, then cooled to room temperature, and dissolved by adding 1mL of anhydrous ethyl acetate; weighed 4-diol-HABI molecule (156.4mg, 0.203mmol) and the free radical quenching substance hexaarylbiimidazole (HABI) (23...

Embodiment 2

[0082] PEG with a molecular weight of 400 400 It is an oligomer diol, MDI is a diisocyanate, and a trihydroxyl-functionalized hexaarylbiimidazole crosslinker molecule (3-diol-HABI) is used as a raw material to synthesize a positive-active polyurethane based on a hexaarylbiimidazole molecular switch. photoresist material. The molecular structure of the 3-diol-HABI crosslinking agent is shown in formula (9).

[0083]

[0084] Weigh PEG 400 (0.213g; 0.533mmol) was vacuum-dried at 70°C for about 1h until no bubbles were generated, then cooled to room temperature, and dissolved by adding 1mL of anhydrous ethyl acetate; weighed 3-diol-HABI molecule (150.3mg, 0.203mmol) and the free radical quenching substance hexaarylbiimidazole (HABI) (239.6mg, 0.406mmol) were dissolved with 4mL of anhydrous ethyl acetate, and then injected into the PEG dry spare double port with a 5mL syringe In the round bottom flask, continue to evacuate and stir evenly; obtain glue A; the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com