Method for preparing CuCrZr/316L connecting piece based on laser additive manufacturing technology

A manufacturing technology, laser additive technology, applied in the field of metal materials, can solve problems such as inapplicability to mass industrial production, difficulty in controlling the final quality of samples, and the danger of explosive welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

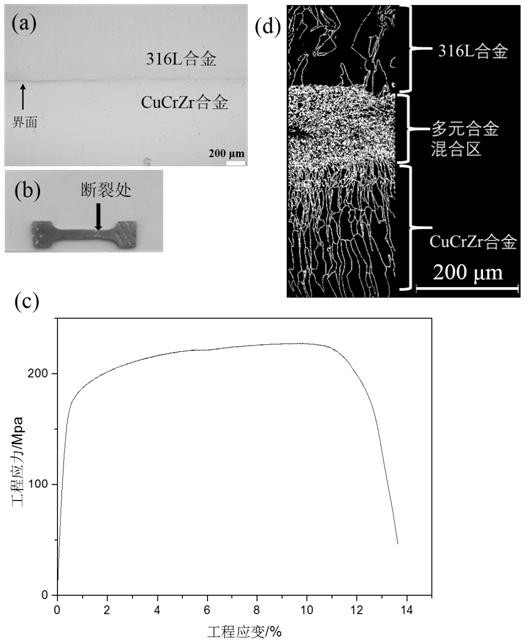

[0035] The CuCrZr material was prepared by selective laser melting (SLM) at a bulk energy density of 400 J / mm 3 , the printing strategy is flat, and the printed size is 12*12*12mm 3 (Length, width and height), after the bottom material CuCrZr alloy is prepared, laser remelting is performed on its surface, and the energy density of the remelted laser body is 200J / mm 3 , the laser remelting strategy is planar, remelting twice. Printing of 316L alloy on CuCrZr remelted surface with a bulk energy density of 70 J / mm 3 , the printing strategy is plane, and its size is 10*10*10mm 3 (LWH). The printed CuCrZr / 316L connector sample was observed by scanning electron microscopy (SEM) at the interface between the 316L material and the CuCrZr material, such as figure 1 As shown in (a), the interface has no obvious defects, and the flatness of the interface meets the requirement of less than 0.5mm. The printed CuCrZr / 316L connector sample was observed by electron backscatter diffraction...

Embodiment 2

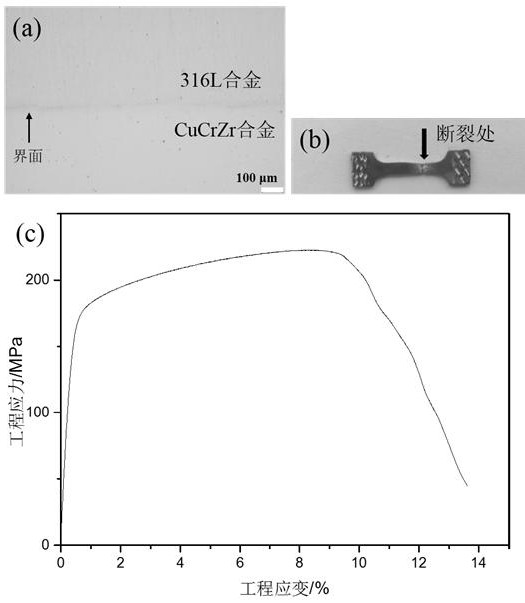

[0038] The CuCrZr material was prepared by selective laser melting (SLM) at a bulk energy density of 600 J / mm 3 , the printing strategy is chessboard, and the printed size is 12*12*12mm 3 (LWH). After the bottom material CuCrZr alloy is prepared, laser remelting is carried out on its surface, and the energy density of the remelted laser volume is 1000 J / mm 3 , the laser remelting strategy is planar, remelting 10 times. Print 316L alloy on CuCrZr remelted surface, the volume energy density used is 100J / mm 3 , the printing strategy is chessboard, its size is 12*12*12mm 3 (LWH). The printed CuCrZr / 316L connector sample was observed by scanning electron microscopy (SEM) at the interface between the 316L material and the CuCrZr material, such as figure 2 As shown in (a), there are no obvious holes in the 316L material, CuCrZr material and the interface between the two, and the interface flatness meets the requirement of less than 0.5mm. A new multi-element alloy mixed region...

Embodiment 3

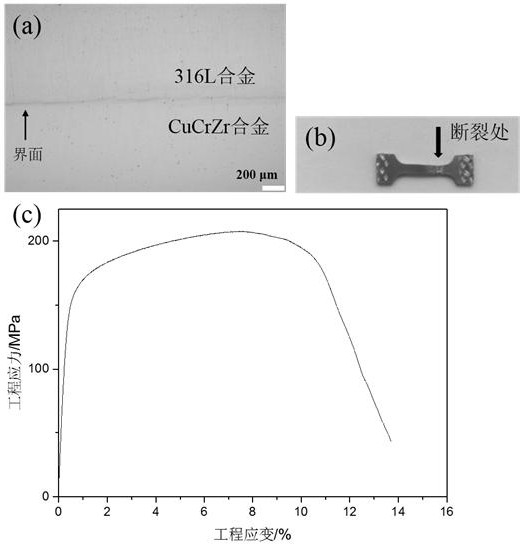

[0041] The CuCrZr material was prepared by selective laser melting (SLM) with a bulk energy density of 1000J / mm 3 , the printing strategy is stripes, and the printed size is 16*16*16mm 3 (Length, width and height), after the bottom material CuCrZr alloy is prepared, laser remelting is performed on its surface, and the energy density of the remelted laser body is 800 J / mm 3 , the laser remelting strategy is planar, remelting 6 times. Printing of 316L alloy on the surface of laser remelted CuCrZr using a bulk energy density of 150 J / mm 3 , the printing strategy is chessboard, its size is 16*16*16mm 3 (LWH). The printed CuCrZr / 316L connector sample was observed by scanning electron microscopy (SEM) at the interface between the 316L material and the CuCrZr material, such as image 3 As shown in (a), 316L material and CuCrZr material and the interface between them have no obvious defects, such as holes, cracks, etc. It can be seen that the flatness of the interface between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tensile properties | aaaaa | aaaaa |

| Tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com