Antibacterial compound material, antibacterial glass, preparation method and application thereof

A kind of antibacterial glass and compound technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems affecting aesthetics and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Another aspect of the embodiments of the present invention also provides a method for preparing highly transparent antibacterial glass, which includes:

[0040] Provides a transparent base,

[0041] The antibacterial compound material is deposited on the transparent substrate by physical vapor deposition method or chemical coating method to form an antibacterial coating and obtain highly transparent antibacterial glass.

[0042] In some embodiments, the physical vapor deposition method includes at least any one of magnetron sputtering, electron beam evaporation and the like, but is not limited thereto.

[0043] In some embodiments, the preparation method of the highly transparent antibacterial glass specifically includes:

[0044] Using magnetron sputtering technology, the M x Zn 1-x ON y A ternary compound is used as a target material, or a mono- or binary compound in M and Zn is used as a target material, and the antibacterial coating is deposited on the transpare...

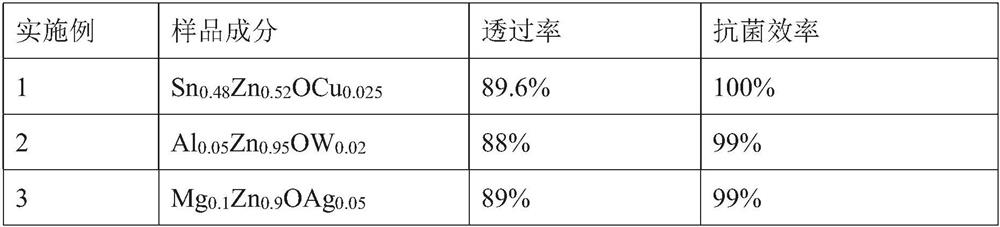

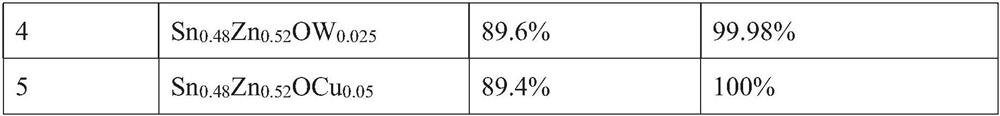

Embodiment 1

[0054] The present embodiment is a kind of preferred antibacterial glass of the present invention, and the material of transparent substrate is glass, and the area is Sn 0.48 Zn 0.52 The 2.5% copper sheet of the O target is attached to it. Vacuum the magnetron sputtering apparatus to an air pressure of 9.0×10 -4 Pa, the cathode is connected to a 100W RF power supply, and the argon gas with a flow rate of 40sccm is introduced to make its working pressure 1.1×10 -1 Pa, the sputtering time is controlled so that the thickness of the deposited antibacterial coating is 10nm, and highly transparent antibacterial glass is obtained. The antibacterial glass has no change in appearance after 1000 hours of high-temperature and high-humidity accelerated aging test (85°C, 85%RH), and does not affect the transmittance and antibacterial efficiency at the same time. The average transmittance of the high-transmittance antibacterial glass in the range of 400-800nm is 89.6%. The inhibition ...

Embodiment 2

[0056] This embodiment is a preferred antibacterial glass of the present invention, and the material of the transparent substrate is glass. Sputtering target composition is Al 0.05 Zn 0.95 ow 0.02 . Vacuum the magnetron sputtering apparatus to a pressure of 7.0×10 -4 Pa, the cathode is connected to a 100W RF power supply, and the argon gas with a flow rate of 40sccm is introduced to make its working pressure 2×10 -1 Pa, the sputtering time is controlled so that the thickness of the deposited antibacterial coating is 100nm, and a highly transparent antibacterial glass is obtained. Its average transmittance in the range of 400-800nm is 88%. The inhibition rate of the high-transparency antibacterial glass to Escherichia coli was measured by the elution method, and it reached 99%. The results of the transmittance and antibacterial rate can be seen in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com