Environment-friendly maintenance car washing liquid as well as preparation method and use method thereof

A car washing liquid and environment-friendly technology, applied in the field of car washing liquid, can solve the problems of high operating costs, waste of water sources, increase costs, etc., and achieve the effect of facilitating the transportation process and preparation process, protecting the environment, and improving the quality of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

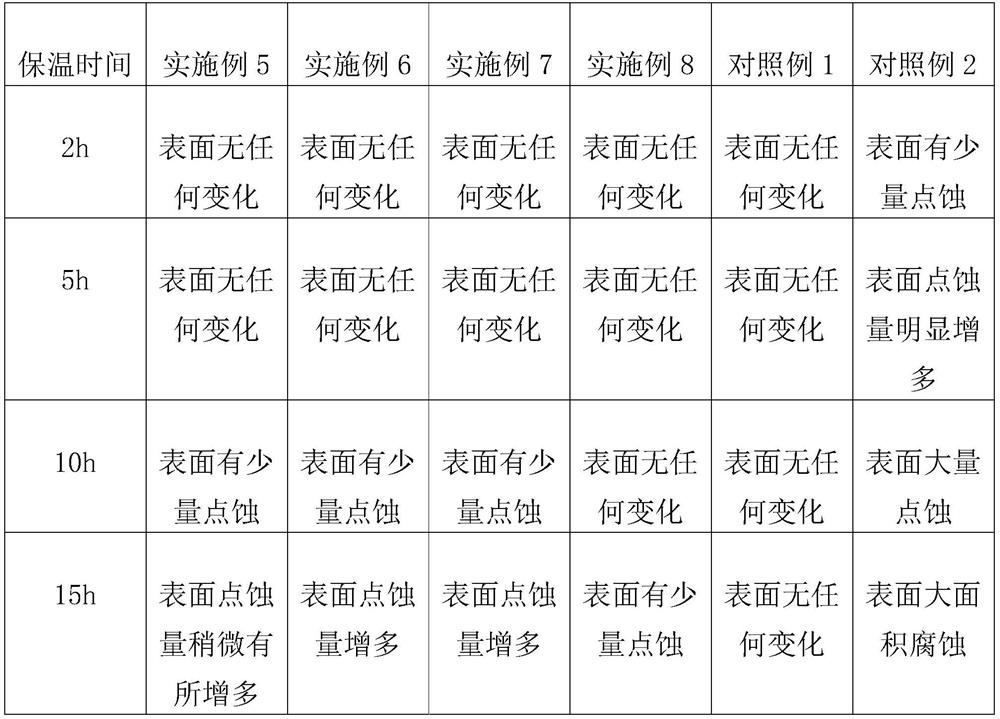

Examples

Embodiment 1

[0035] A method for preparing an environment-friendly maintenance car wash liquid, comprising selecting 100 grams of silicone gel, 250 grams of carnauba wax, and 1,500 grams of water according to corresponding proportions and mixing them, heating at 30 degrees Celsius until evenly stirred, and then continuing to add ethylene oxide After 700 grams are mixed, add 450 grams of regulators to adjust the pH to 5.8-6.9 to obtain a milky liquid product.

[0036] A method of using an environment-friendly maintenance car wash liquid. The finished product prepared above is used to mix deionized water, and the volume ratio is diluted to a finished product: water (V / V) 1:200. After that, it is directly sprayed on the car body, wiped with a towel, and used. .

Embodiment 2

[0038] A method for preparing an environment-friendly maintenance car wash liquid, comprising selecting 500 grams of silicone gel, 1400 grams of lanolin and 5000 grams of water according to corresponding proportions, mixing them, heating at 60 degrees Celsius until they are evenly stirred, and then continuing to add 2400 grams of ethylene oxide After mixing evenly, 900 grams of regulators are added to adjust the pH to 5.8-6.9 to obtain a milky liquid product.

[0039] A method of using an environment-friendly maintenance car wash liquid. The finished product prepared above is used to mix deionized water, and the volume ratio of the diluted product: water (V / V) is 1:500. After that, it is directly sprayed on the car body, wiped with a towel, and used. .

Embodiment 3

[0041] A preparation method of an environment-friendly maintenance car wash liquid, comprising selecting 250 grams of silicone gel, 500 grams of sodium stearate and 2,500 grams of water according to corresponding proportions, mixing them, heating at 30 degrees Celsius until they are evenly stirred, and then continuing to add ethylene oxide After mixing 1100 grams of alkanes, 620 grams of regulators were added to adjust the pH to 5.8-6.9 to obtain a milky liquid product.

[0042] A method of using an environment-friendly maintenance car wash liquid. The finished product prepared above is used to mix deionized water, and the volume ratio is diluted to a finished product: water (V / V) 1:200. After that, it is directly sprayed on the car body, wiped with a towel, and used. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com