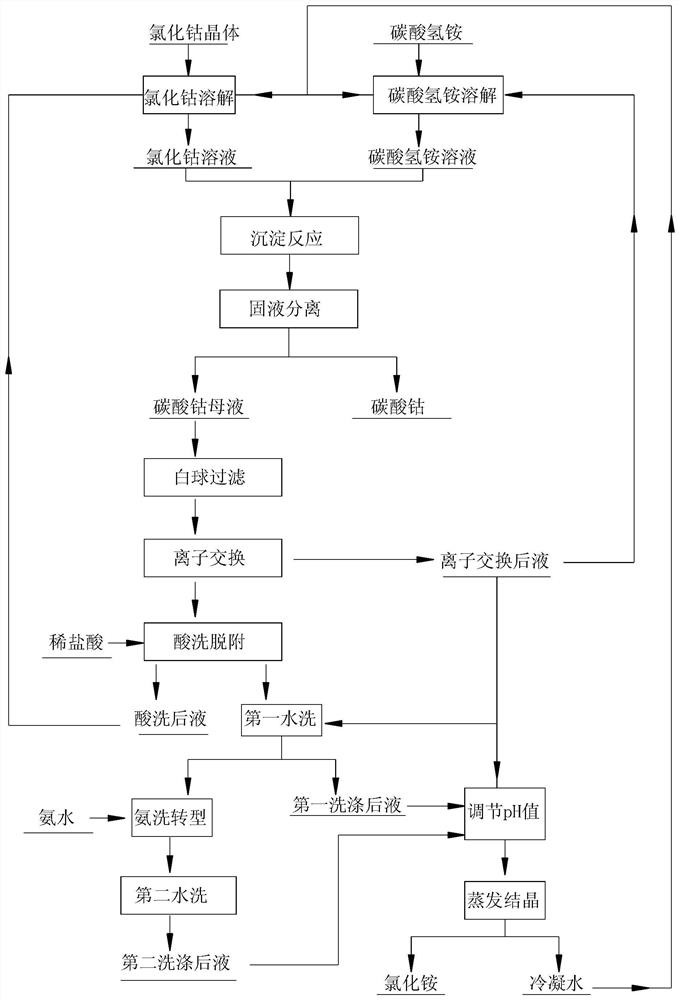

Method for treating cobalt carbonate mother liquor in preparation process of spherical cobalt carbonate

A technology of cobalt carbonate mother and treatment method, applied in the field of metallurgy, can solve the problems of equipment and product impact, cobalt not being effectively recovered, and reducing the quality of by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

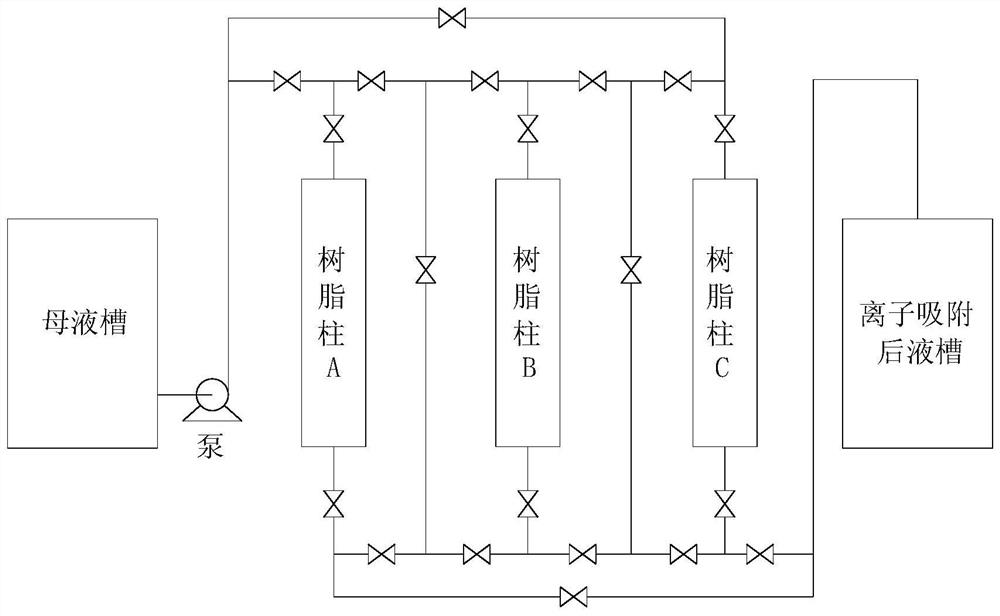

[0030] First, the ion adsorption device will be described below, please refer to figure 2 , the ion adsorption device includes three groups of ion exchange columns, the three groups of ion exchange columns are respectively A group of ion exchange columns, B group of ion exchange columns and C group of ion exchange columns, in the present embodiment, each group of ion exchange columns only includes An ion exchange column, wherein the ion exchange column of group A is resin column A, the ion exchange column of group B is resin column B, and the ion exchange column of group C is resin column C.

[0031] Resin column A, resin column B and resin column C are connected with pipes and valves to form a series two-stage adsorption combination of any two resin columns.

[0032] When working, any two of the three resin columns are used in series, and the other is for standby. When one of the resin columns is saturated with adsorption, it stops running and desorbs. The spare resin column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com