A method for cooperating with copper smelting slag to treat gold-containing waste slag

A technology for copper smelting slag and waste slag, which is applied to the treatment field of copper smelting slag and gold-containing waste slag, can solve the problems of high content of copper matte impurities, reduce the quality of copper matte, deteriorate the properties of slag, etc., and achieve high-efficiency enrichment, low cost, Handling large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

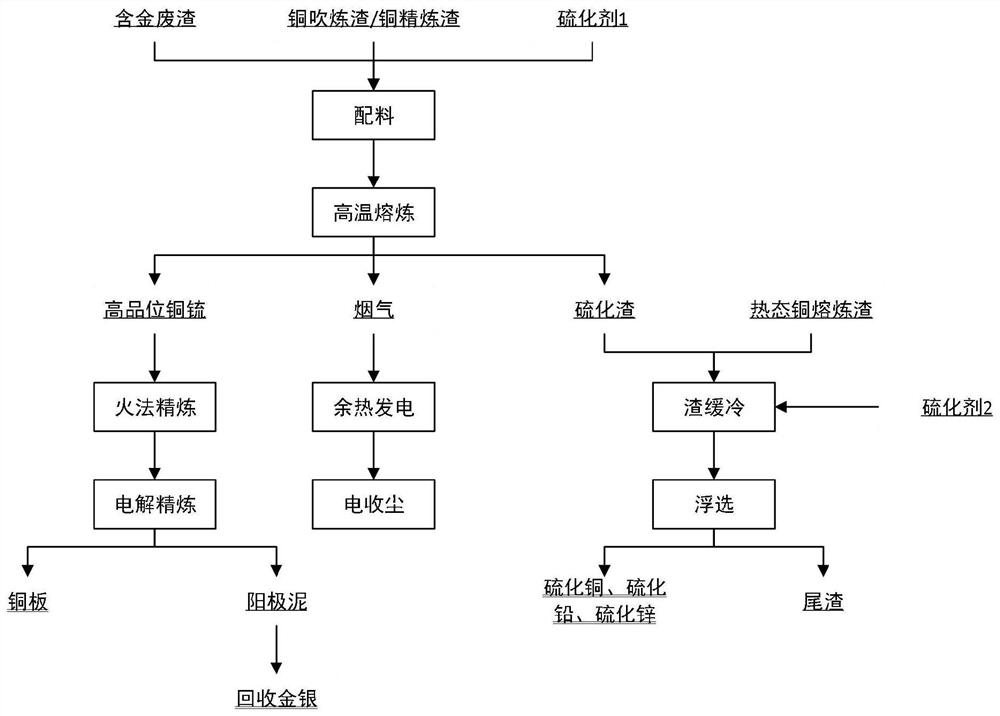

[0037] like figure 1 As shown, a method for cooperating with copper smelting slag to process gold-containing waste slag includes the following steps:

[0038] (1) Using 300g of hot copper smelting slag as raw material, its main chemical composition includes Cu26.2%, Pb8.9%, Zn3.41%, Fe30.2%, SiO 2 1.56%, CaO8.68%. 30g of gold cyanide tailings were added to the molten copper smelting slag through the feeding device, and the chemical composition of the gold cyanide tailings included SiO 2 60%, Au5g / t, Ag30.2g / t, Fe7.8%, and add 30g of pyrite, keep smelting at 1300°C for 2h, to obtain copper matte and sulfide slag. The grade of copper matte is 60.62%; the sulfide slag contains 1% copper, 0.11g / t gold and 0.5g / t silver, and lead and zinc basically exist in the sulfide state in the sulfide slag.

[0039] (2) Mix the hot sulfide slag with the hot smelting slag. The main chemical composition of the smelting slag includes Cu3.03%, Pb0.53%, Zn2.72%, Fe40.31%, SiO 2 21.1%, CaO1.62%....

Embodiment 2

[0041] like figure 1 As shown, a method for cooperating with copper smelting slag to process gold-containing waste slag includes the following steps:

[0042] (1) Using 300g copper flash smelting slag as raw material, its main chemical composition includes Cu26.2%, Pb8.9%, Zn3.41%, Fe30.2%, SiO 2 1.56%, CaO8.68%. 50g of gold cyanide tailings were added to the molten copper smelting slag through the feeding device, and the chemical composition of the gold cyanide tailings included SiO 2 60%, Au5g / t, Ag30.2g / t, Fe7.8%, and add 45g of pyrite, keep smelting at 1300°C for 2h, to obtain copper matte and sulfide slag. The grade of copper matte is 58.3%; the sulfide slag contains 1.1% copper, 0.14g / t gold, 0.56g / t silver, and lead and zinc basically exist in the sulfide state in the sulfide slag.

[0043] (2) Mix the hot sulfide slag with the hot smelting slag. The main chemical composition of the smelting slag includes Cu3.03%, Pb0.53%, Zn2.72%, Fe40.31%, SiO 2 21.1%, CaO1.62%. ...

Embodiment 3

[0045] like figure 1 As shown, a method for cooperating with copper smelting slag to process gold-containing waste slag includes the following steps:

[0046] (1) Using 300g copper smelting slag as raw material, its main chemical composition includes Cu26.2%, Pb8.9%, Zn3.41%, Fe30.2%, SiO 2 1.56%, CaO8.68%. 50g of gold cyanide tailings were added to the molten copper smelting slag through the feeding device, and the chemical composition of the gold cyanide tailings included SiO 2 65.2%, Au4.5g / t, Ag40.2g / t, Fe9.8%, and add 45g of pyrite, keep smelting at 1300 ℃ for 2h, to obtain copper matte and sulfide slag. The grade of copper matte is 59.62%; the sulfide slag contains 0.82% copper, 0.19g / t gold and 0.39g / t silver, and lead and zinc basically exist in the sulfide state in the sulfide slag.

[0047] (2) Mix the hot sulfide slag with the hot smelting slag. The main chemical composition of the smelting slag includes Cu3.03%, Pb0.53%, Zn2.72%, Fe40.31%, SiO 2 21.1%, CaO1.62%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com