Preparation method of silicon nanostructure and laser

A silicon nanotechnology, laser technology, applied in lasers, laser parts, nanotechnology and other directions, can solve the problem of the quality of silicon needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

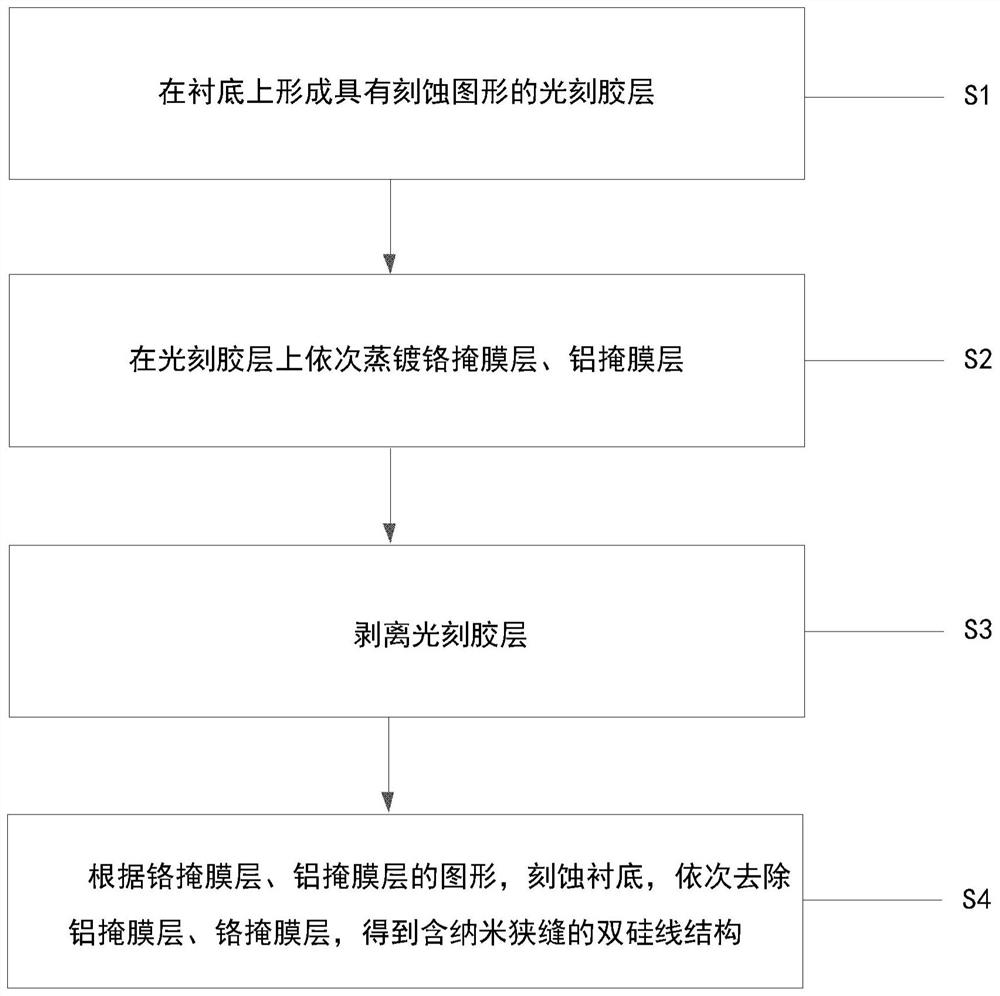

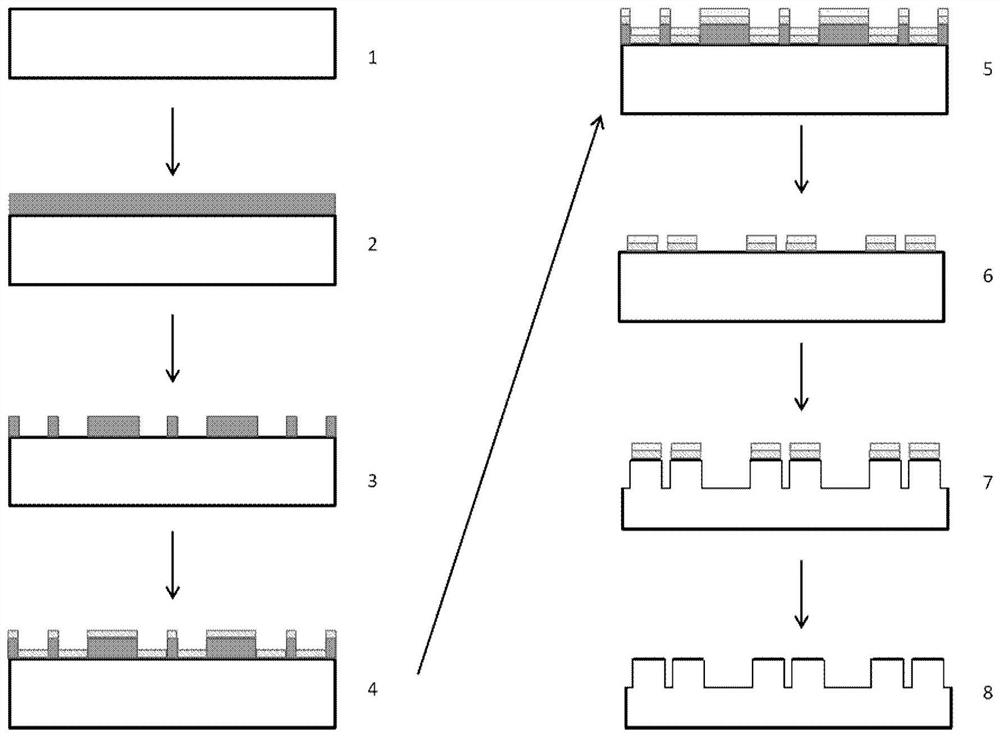

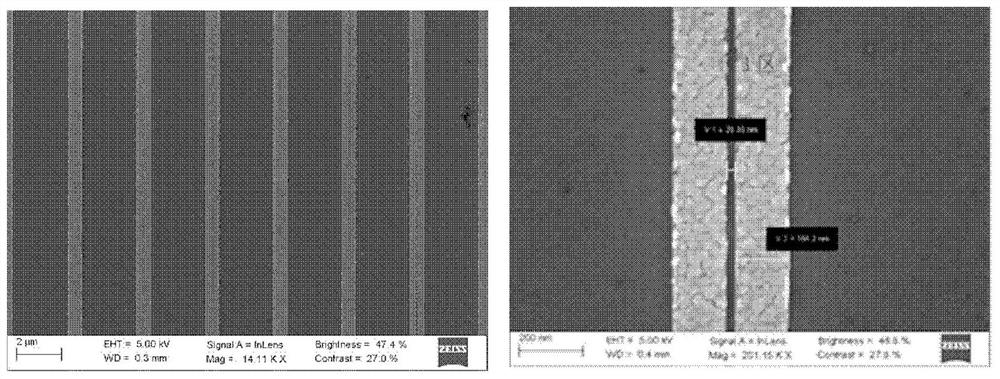

[0051] figure 2 Schematically showing a structural diagram of a method for preparing a silicon nanostructure according to an embodiment of the present disclosure, which completely includes the following steps:

[0052] Step 1, providing an SOI sheet substrate;

[0053] Step 2. Carry out electron beam lithography on the SOI sheet substrate. The selected photoresist is PMMA A2 electron beam glue. Before coating, bake the SOI sheet at 150° for 2 minutes to dry the surface moisture of the SOI sheet. During spin coating, 4000 Turn and bake at 180° for 2 minutes to form an electron beam photoresist film of about 70nm;

[0054] Step 3, forming a pattern by electron beam lithography, which is equivalent to step S1;

[0055] Step 4, electron beam evaporation, evaporation metal mask Cr, its thickness is 5nm;

[0056] Step 5, electron beam evaporation, evaporating metal mask Al, the thickness of which is 15nm, which is equivalent to step S2;

[0057] Step 6, peel off the photoresist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com