A segmental delay compensation strategy for surface-mounted permanent magnet synchronous motor without position sensor

A technology of permanent magnet synchronous motor and delay compensation, which is applied in the control of generators, motor control, motor generator control, etc., can solve the problems of dynamic and stability effects of position observers, improve the accuracy of position estimation, avoid The effect of phase delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0066] A segmental delay compensation strategy for a surface-mounted permanent magnet synchronous motor without a position sensor according to the present invention is specifically implemented according to the following steps:

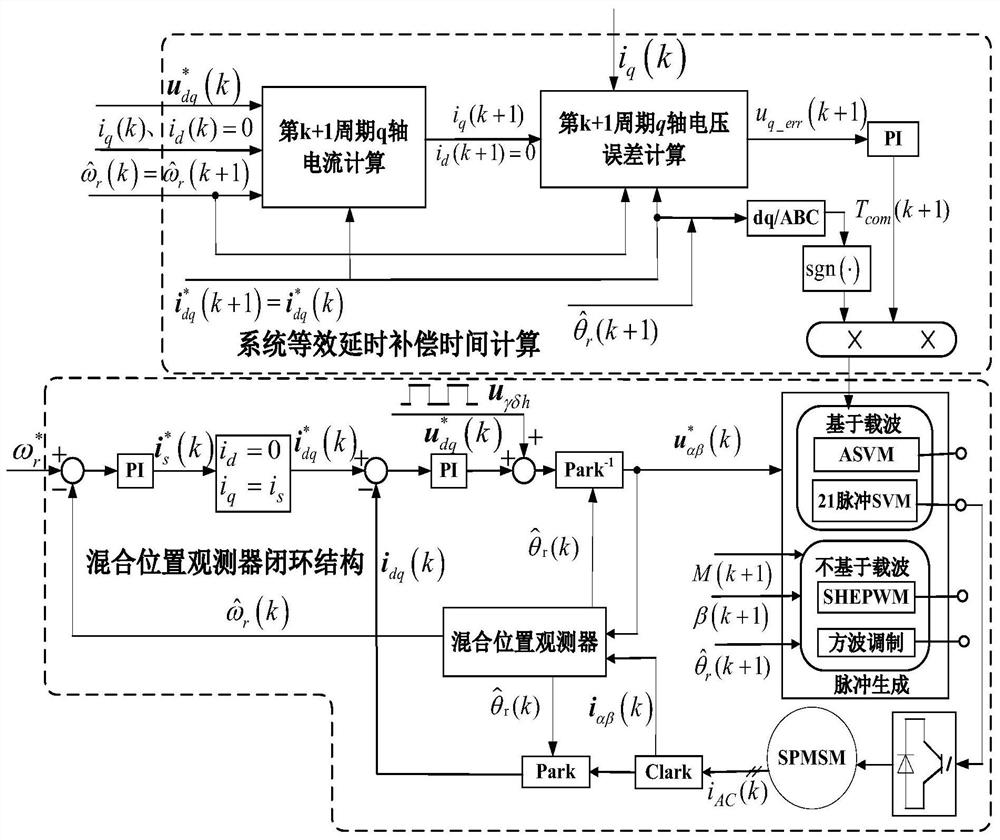

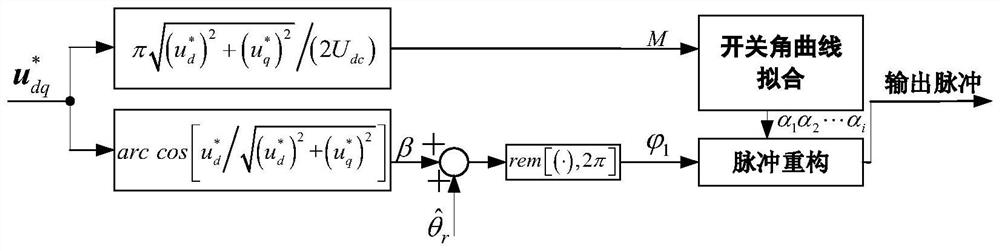

[0067] Step 1, use carrier modulation in the low-speed area to perform PI adjustment on the predicted q-axis voltage error, so as to obtain the compensation time, and then eliminate the influence of the total system delay by compensating the conduction time of the IGBT. The block diagram is as follows figure 1 shown; specifically:

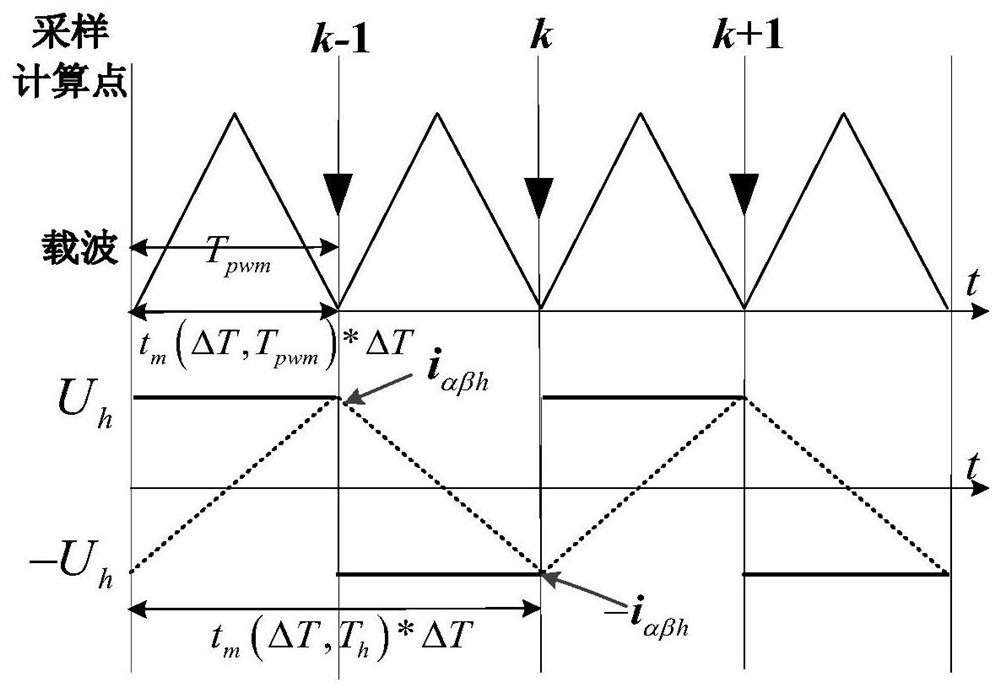

[0068] Step 1.1, when the fundamental wave frequency of the motor is less than 47Hz, use the square wave voltage injection method, set the carrier frequency to 500Hz, inject a square wave voltage signal with an amplitude of 15V and a frequency of 250Hz to the d-axis, and the injection sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com