Method for continuously producing epoxypropane by propane two-step method

A propylene oxide, two-step technology, applied in hydrogen/synthesis gas production, chemical instruments and methods, peroxygen compound preparation, etc., can solve the problem of large consumption, inflexible sales, difficulty in improving the selectivity of propylene oxide, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 9

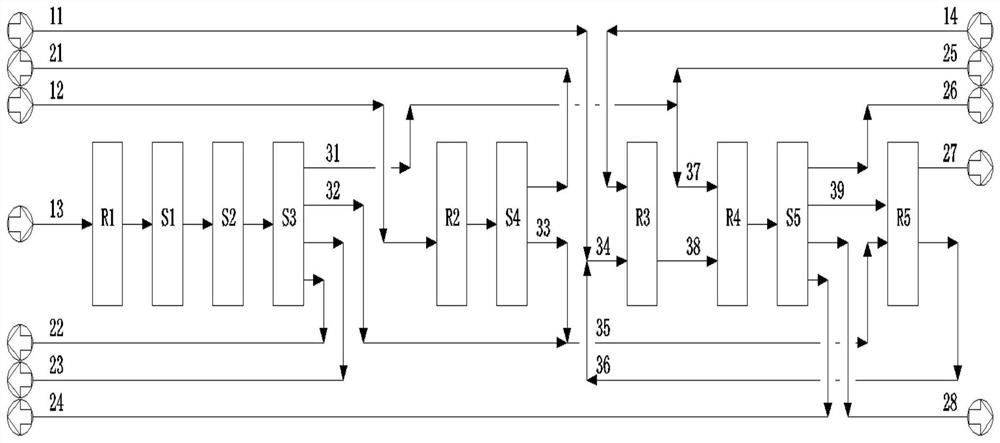

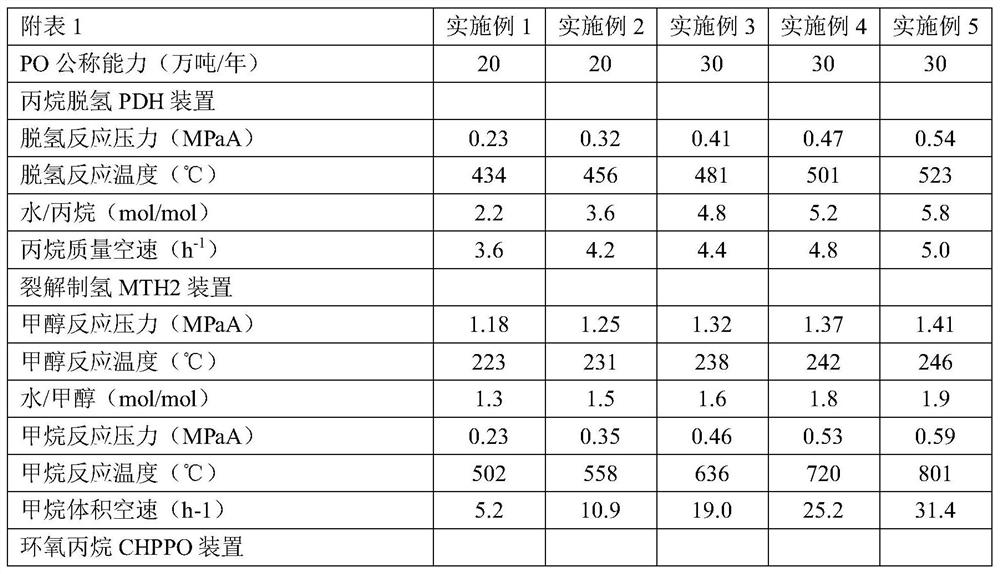

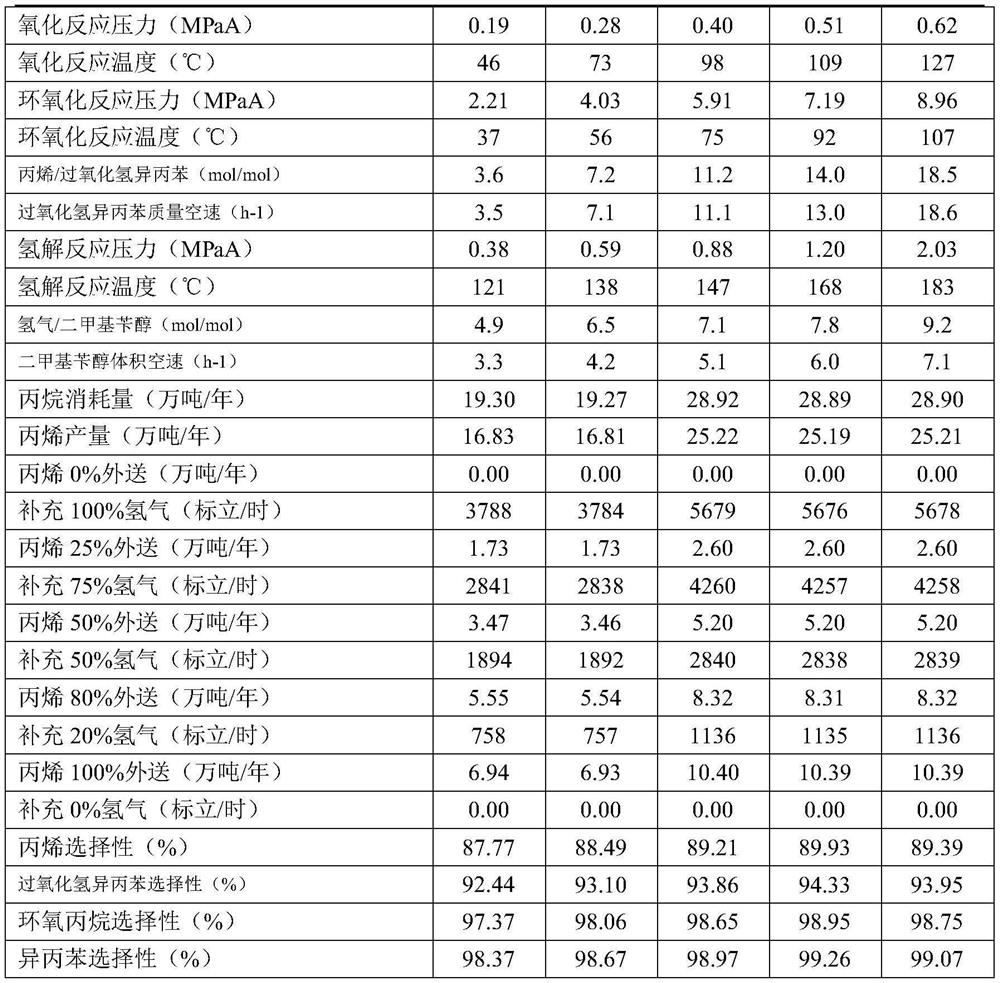

[0029] Such as figure 1 , the present embodiment relates to a method for the continuous production of propylene oxide by a two-step method of propane. In a large-scale commercial propylene oxide production device with a nominal capacity of 50,000-900,000 tons / year, the process flow is as follows: Propane 13 from outside the boundary Enter the dehydrogenation unit R1 for dehydrogenation reaction to generate propylene, then cool through the quenching unit S1, pressurize the compression unit S2, and separate the propylene 31, hydrogen 32, carbon two components 22, and carbon four components 23 in the separation unit S3; 31 is divided into two, a part of propylene 25 is sent out of bounds, carbon two components 22, and carbon four components 23 are also sent out of bounds. Methanol 12 from outside enters the cracking unit R2 for cracking reaction to generate hydrogen, and then the purified hydrogen 33 is combined with the hydrogen 32 produced by the device through the purification u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com