Expanded graphite composite inorganic hydrated salt phase change material and preparation method thereof

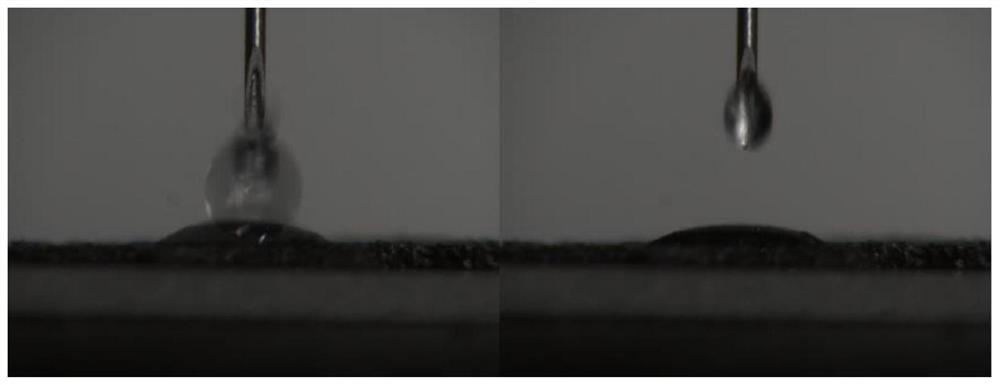

A technology of inorganic hydrated salt and expanded graphite, which is used in the preparation of expanded graphite composite inorganic hydrated salt phase change materials, and the field of expanded graphite composite inorganic hydrated salt phase change materials, which can solve the problems of corrosion of surrounding media, poor stability, easy leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

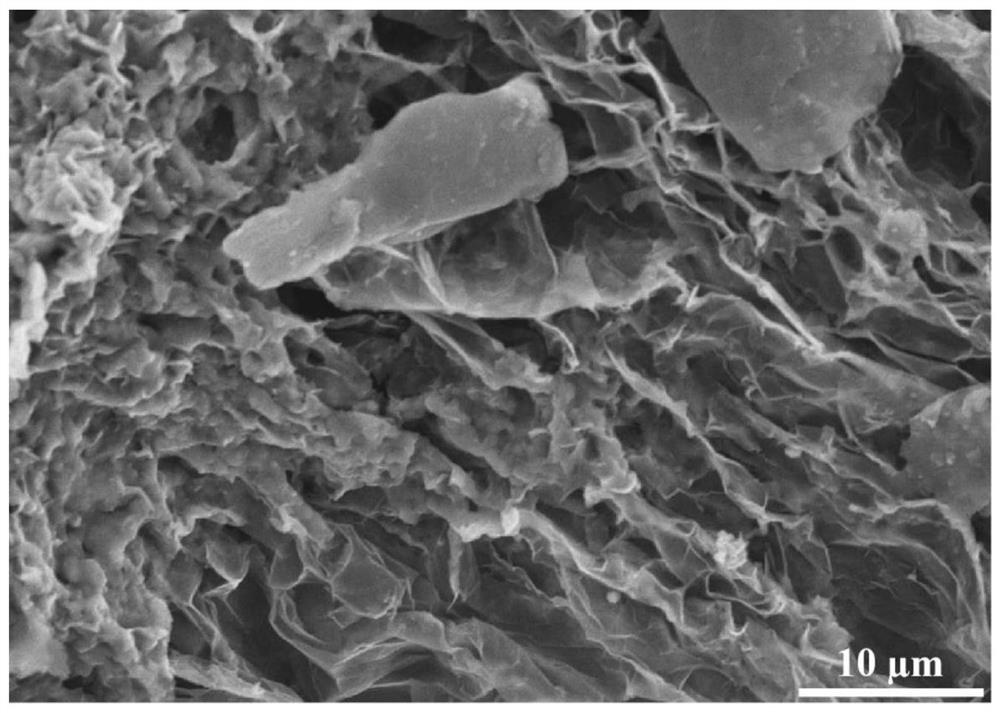

[0036] (1) Disperse 0.3g of sodium lauryl sulfate in 10mL of absolute ethanol, and ultrasonicate at room temperature with a power of 360W for 10min until the solution becomes clear, and obtain the soaking solution for modification;

[0037] (2) Put 0.3g of expanded graphite in the soaking solution for modification, let it stand in a vacuum environment for 10 minutes, then take it out, dry it at 80°C for 30 minutes, and cool to room temperature to obtain the modified expanded graphite matrix material;

[0038] (3) Ultrasonicate the excess liquid disodium hydrogen phosphate dodecahydrate until it is completely clarified in a water bath at 50°C, and slowly add it dropwise to the modified expanded graphite matrix material until it is completely submerged. In the ultrasonic cleaning machine, heat the water bath and perform ultrasonication while vacuuming, take it out after vacuum ultrasonication for 5 minutes, repeatedly use filter paper to remove excess liquid disodium hydrogen pho...

Embodiment 2

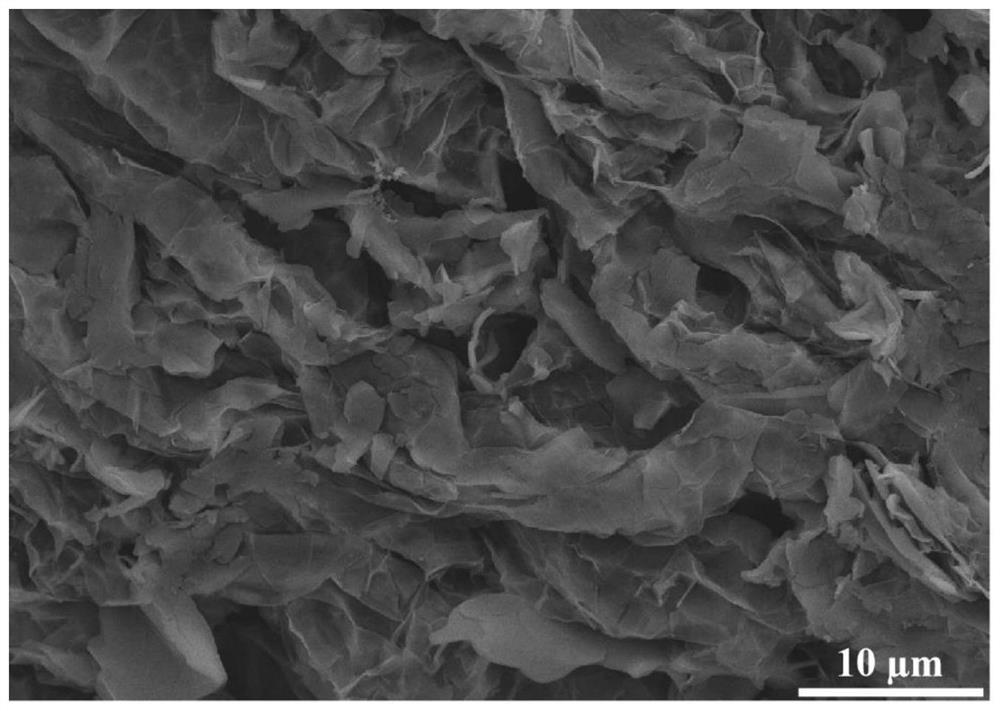

[0041](1) Disperse 0.1g of cetyltrimethylammonium chloride in 10mL of absolute ethanol, and ultrasonicate for 10min at room temperature with a power of 360W until the solution becomes clear to obtain the soaking solution for modification;

[0042] (2) Put 0.3g of expanded graphite in the soaking solution for modification, let it stand in a vacuum environment for 10 minutes, then take it out, dry it at 80°C for 30 minutes, and cool it to room temperature to obtain the modified expanded graphite matrix material;

[0043] (3) Ultrasonicate the excess liquid disodium hydrogen phosphate dodecahydrate in a 50°C water bath until it is completely clarified, and slowly add it dropwise to the modified expanded graphite matrix material until it is completely submerged. Under a 50°C water bath, place the vacuum device on In the ultrasonic cleaning machine, heat the water bath and perform ultrasonication while vacuuming, take it out after vacuum ultrasonication for 5 minutes, repeatedly use...

Embodiment 3

[0046] (1) Disperse 0.1g of dodecyltrimethylammonium bromide in 10mL of absolute ethanol, and ultrasonicate for 10min at room temperature with a power of 360W until the solution becomes clear to obtain the soaking solution for modification;

[0047] (2) Put 0.3g of expanded graphite in the soaking solution for modification, let it stand in a vacuum environment for 10 minutes, then take it out, dry it at 80°C for 30 minutes, and cool it to room temperature to obtain the modified expanded graphite matrix material;

[0048] (3) Ultrasonicate the excess liquid disodium hydrogen phosphate dodecahydrate in a 50°C water bath until it is completely clarified, and slowly add it dropwise to the modified expanded graphite matrix material until it is completely submerged. Under a 50°C water bath, place the vacuum device on In the ultrasonic cleaning machine, heat the water bath and perform ultrasonication while vacuuming, take it out after vacuum ultrasonication for 5 minutes, repeatedly u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com