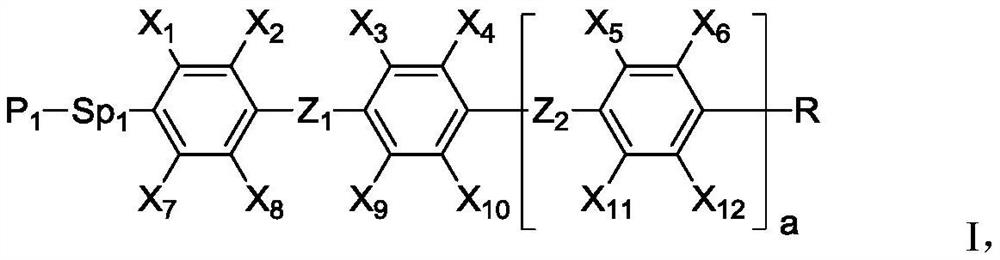

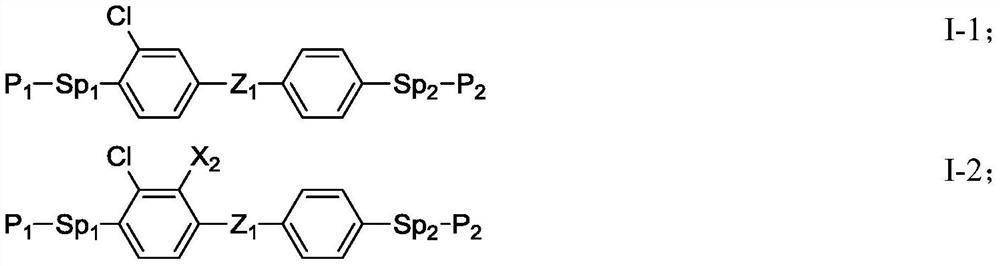

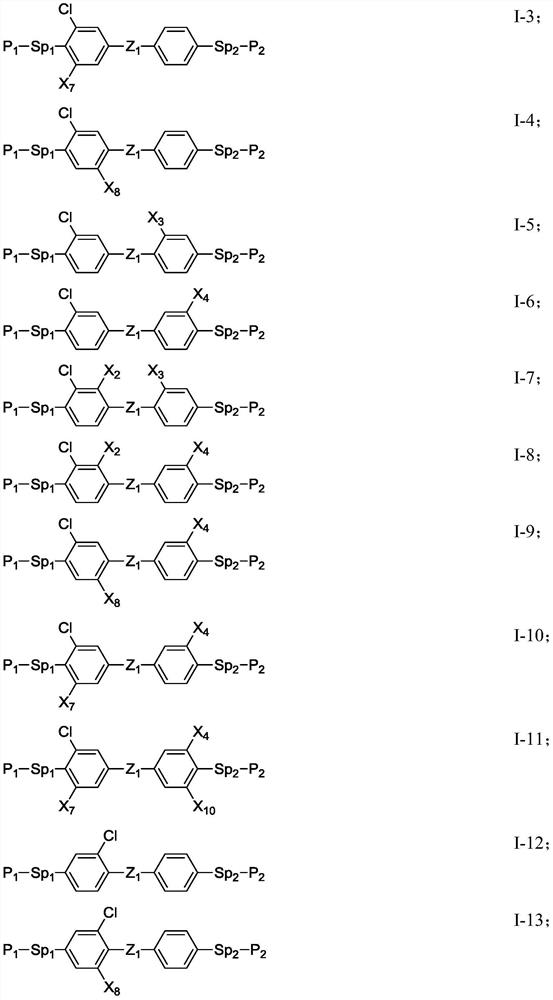

Polymerizable compound, liquid crystal composition, and liquid crystal display device

A polymer compound and liquid crystal composition technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as poor solubility and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0167] (1) Preparation of compound 1-3

[0168] Add 35g (169mmol) compound 1-1, 24.42g (177mmol) compound 1-2, 175mL toluene, 100mL ethanol, 100mL water, 29.76g (354mmol) sodium bicarbonate and 0.07g (0.1mmol) to a 500mL three-necked flask ) dichlorodi-tert-butyl-(4-dimethylaminophenyl)phosphine palladium(II). The mixture was replaced with nitrogen for 3 times, and the mixture was reacted for 2 hours under the condition that the temperature was controlled at 60° C. to 70° C.

[0169] The reaction solution was cooled to room temperature, and allowed to stand for liquid separation. The aqueous phase was extracted with 2 x 100 mL of toluene, and all organic phases were combined. The combined organic phases were sequentially washed with 3×80 mL of water, dried over anhydrous sodium sulfate, and concentrated to obtain a crude product. Then, 4 times the volume of petroleum ether was added to the crude product, and after beating at room temperature for 2 hours, it was frozen and c...

Embodiment 3-6

[0252] Table 5 Composition and performance parameters of Host 2

[0253]

[0254] To 100 parts by weight of the above-mentioned Host 2, add polymerizable compounds of the type and parts by weight shown in Table 5 below, and perform Ra, ΔPTA and t -20℃ And other performance tests, the results are as follows:

[0255] table 5

[0256]

[0257] It can be seen from the above Table 5 that the liquid crystal composition containing the polymerizable compound of the general formula I of the present invention has low roughness after the polymerization reaction occurs (that is, has a high degree of uniformity), and its pretilt angle is affected by ultraviolet light and long The change caused by time energization is small (that is, the stability is high), and it also has good low-temperature stability and a wide range of applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com