Pulse copper electroplating additive, electroplating solution and application of electroplating solution

A technology of pulse electroplating and additives, applied in jewelry and other fields, can solve problems such as crystallization of electroplated copper and reduction of mechanical properties of electroplated copper layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

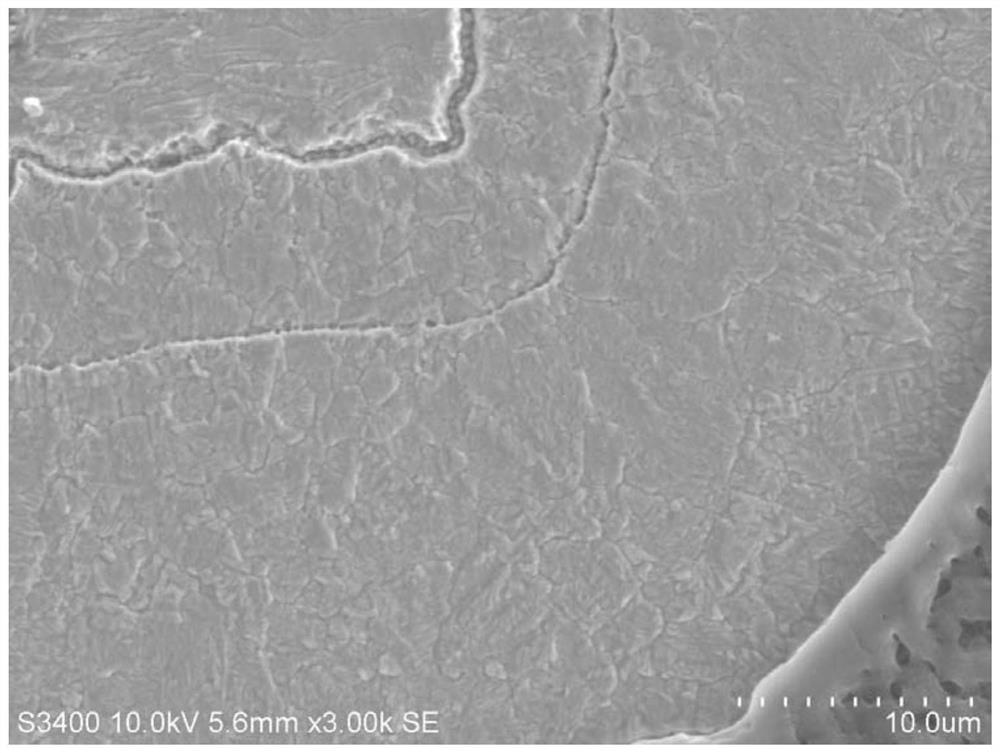

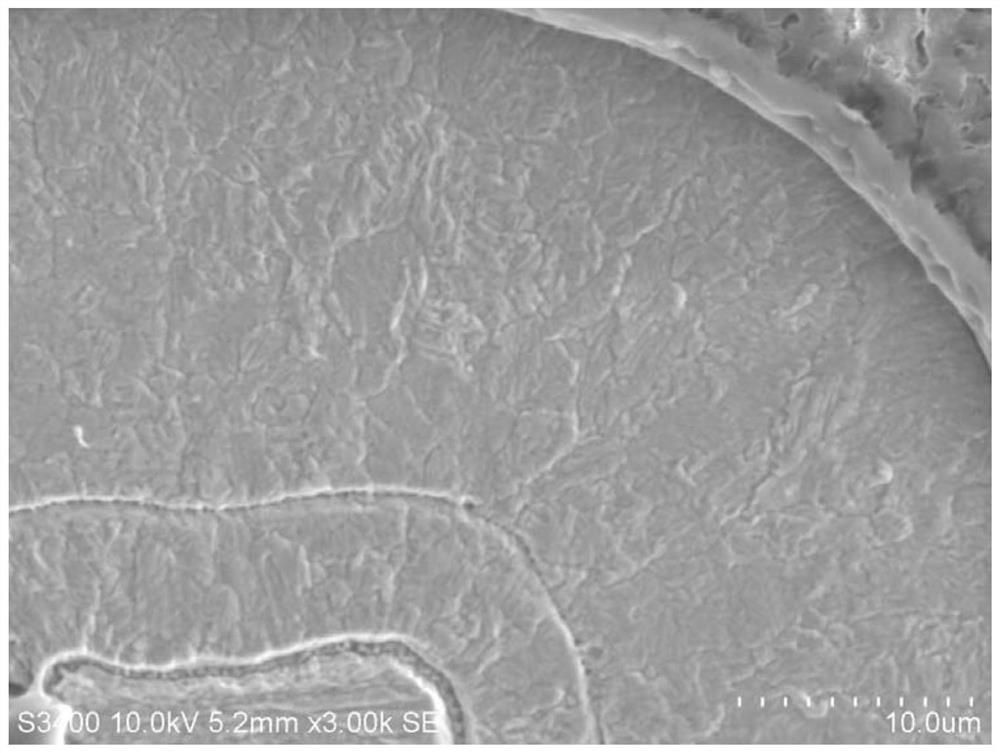

Image

Examples

Embodiment 1

[0020] This embodiment provides a kind of pulse electroplating copper additive, and this additive is the solution that is made by sulfonate, organic amine modified glycidyl ether, polyether compound and deionized water, and in solution, described sulfonate is 3- (Benzothiazole-2-mercapto)-sodium propanesulfonate and sodium mercaptoimidazole benzenesulfonate, the mass concentration of the 3-(benzothiazole-2-mercapto)-propanesulfonate sodium is 2g / L, the described The mass concentration of sodium mercaptoimidazole benzenesulfonate is 3g / L. The organic amine-modified glycidyl ether is prepared by polycondensation of an organic amine with polyethylene glycol diglycidyl ether or castor oil diglycidyl ether at a molar ratio of 2:1. Specifically, this example The described organic amine-modified glycidyl ether comprises a polycondensate made of ethylamine and polyethylene glycol diglycidyl ether with a concentration of 30g / L and a polycondensate made of ethylenediamine and polyethyle...

Embodiment 2

[0024] This embodiment provides a kind of pulse electroplating copper additive, and this additive is the solution that is made by sulfonate, organic amine modified glycidyl ether, polyether compound and deionized water, and in solution, described sulfonate is 3- (Benzothiazole-2-mercapto)-propanesulfonate sodium, 2-mercaptobenzimidazole-5-sodium sulfonate and 3-(5-mercapto-1-tetrazolyl)sodium benzenesulfonate, the 3- The mass concentration of (benzothiazole-2-mercapto)-propanesulfonate sodium is 1g / L, and the mass concentration of the 2-mercaptobenzimidazole-5-sodium sulfonate is 1g / L, and the 3-(5 -The mass concentration of sodium mercapto-1-tetrazolyl)benzenesulfonate is 2g / L. The organic amine-modified glycidyl ether is prepared by polycondensation of an organic amine with polyethylene glycol diglycidyl ether or castor oil diglycidyl ether at a molar ratio of 2:1. Specifically, this example The organic amine-modified glycidyl ether includes a polycondensate made of ethylen...

Embodiment 3

[0028] This embodiment provides a kind of pulse electroplating copper additive, and this additive is the solution that is made by sulfonate, organic amine modified glycidyl ether, polyether compound and deionized water, and in solution, described sulfonate is 3- (Benzothiazole-2-mercapto)-propanesulfonate sodium, the mass concentration of the 3-(benzothiazole-2-mercapto)-propanesulfonate sodium is 5g / L. The organic amine-modified glycidyl ether is prepared by polycondensation of an organic amine with polyethylene glycol diglycidyl ether or castor oil diglycidyl ether at a molar ratio of 2:1. Specifically, this example The organic amine-modified glycidyl ether is a condensation polymer prepared from propylenediamine and polyethylene glycol diglycidyl ether with a concentration of 10 g / L. The polyether compound is 1,2-propylene glycol polyoxypropylene polyoxyethylene ether, and the mass concentration of the 1,2-propylene glycol polyoxypropylene polyoxyethylene ether is 10 g / L. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com