Silt slope stability control method for fixing slope by using chemical improvement reagent

A technology of stability control and chemical improvement, applied in the direction of chemical instruments and methods, excavation, application, etc., can solve problems such as collapse and easy deformation of foundation pit construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

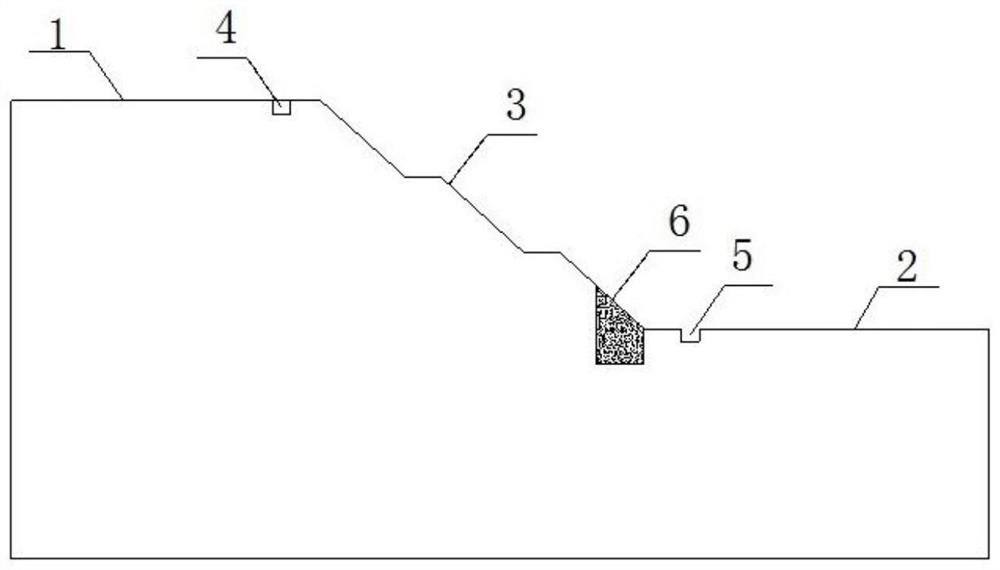

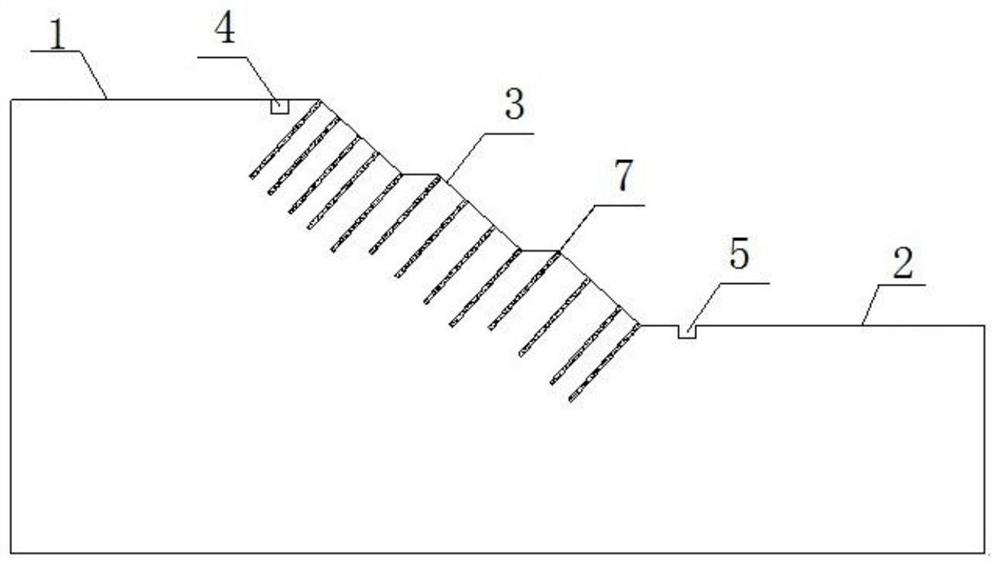

[0046] This embodiment discloses a method for controlling the stability of a silt slope using chemical improvement reagents for slope consolidation, including the following steps:

[0047] 1) Configure chemical improvement reagents. Wherein, the chemical improvement reagent is made by mixing improved materials with water, the improved materials are lime, sodium silicate, silicon micropowder or calcium lignosulfonate, and the mass ratio of lime to water is 10:90-15:85, The mass ratio of microsilica powder to water is 10:90-15:85, and the mass ratio of calcium lignosulfonate to water is 10:90-15:85. In this embodiment, sodium silicate is selected as the improved material, and sodium silicate is mixed with water in a predetermined ratio to form water glass.

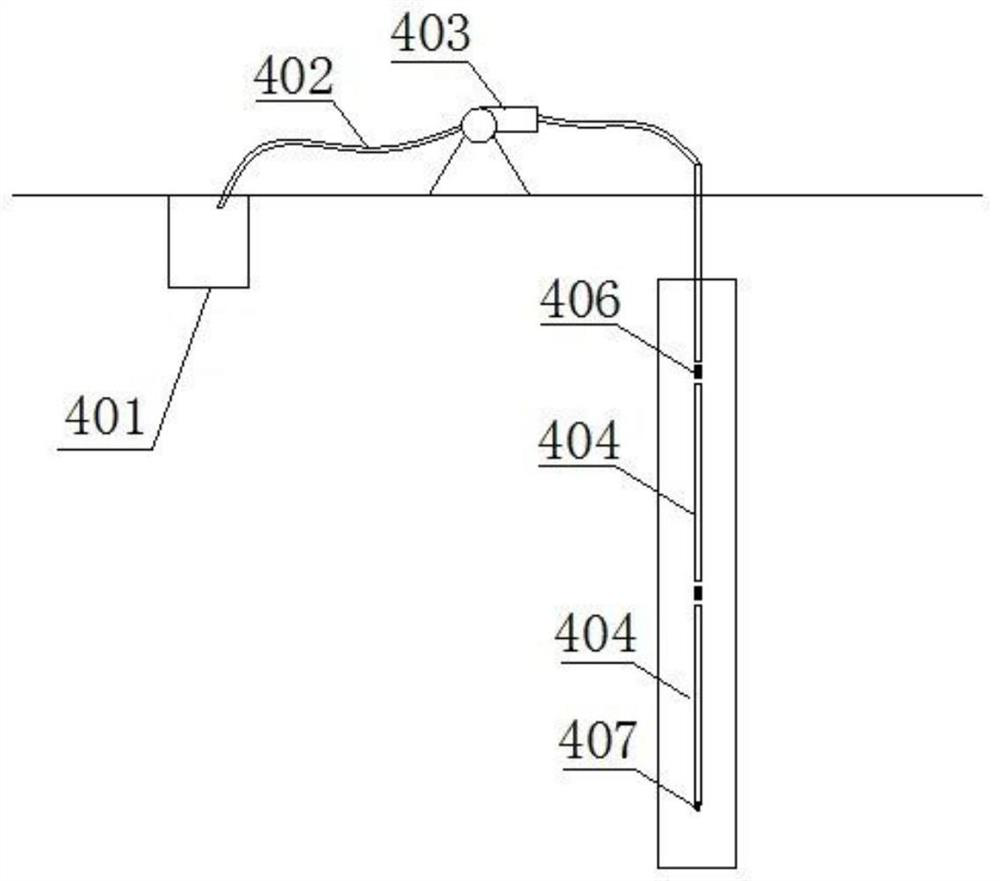

[0048] 2) Put the configured chemical modification reagent into the solution pool 401 .

[0049] 3) see figure 1 , pressing the lower end of the grouting steel pipe 404 into the silt layer of the slope until the pressing ...

Embodiment 2

[0070] This embodiment discloses a method for controlling the stability of a silt slope using chemical improvement reagents for slope consolidation, including the following steps:

[0071] 1) Configure chemical improvement reagents. Wherein, the chemical improvement reagent is made by mixing improved materials with water, the improved materials are lime, sodium silicate, silicon micropowder or calcium lignosulfonate, and the mass ratio of lime to water is 10:90-15:85, The mass ratio of microsilica powder and water is 10:90-15:85, the mass ratio of calcium lignosulfonate and water is 10:90-15:85, and sodium silicate and water are mixed according to a predetermined ratio to form water glass. In this embodiment, lime is selected as the chemical improvement agent, and lime is mixed with water to form a suspension.

[0072] 2) Put the configured chemical modification reagent into the solution pool 401 .

[0073] 3) see figure 1 , pressing the grouting steel pipe 404 into the sil...

Embodiment 3

[0083] This embodiment discloses a method for controlling the stability of a silt slope using chemical improvement reagents for slope consolidation, including the following steps:

[0084] 1) Configure chemical improvement reagents. Wherein, the chemical improvement reagent is made by mixing improved materials with water, the improved materials are lime, sodium silicate, silicon micropowder or calcium lignosulfonate, and the mass ratio of lime to water is 10:90-15:85, The mass ratio of silicon micropowder and water is 10:90-15:85, the mass ratio of calcium lignosulfonate and water is 10:90-15:85, and sodium silicate and water are mixed according to a predetermined ratio to form water glass.

[0085] 2) Put the configured chemical modification reagent into the solution pool 401 .

[0086] 3) Determine the reinforcement method of the slope 3 according to the design reinforcement depth of the slope 3. When the reinforcement depth of the slope 3 is small, spray the prepared chemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com