High-performance single-photon pixel spad structure

A single-photon, high-performance technology, applied in electrical components, diodes, electro-solid devices, etc., to solve problems such as large pixel size, limited application, and difficult SPAD compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

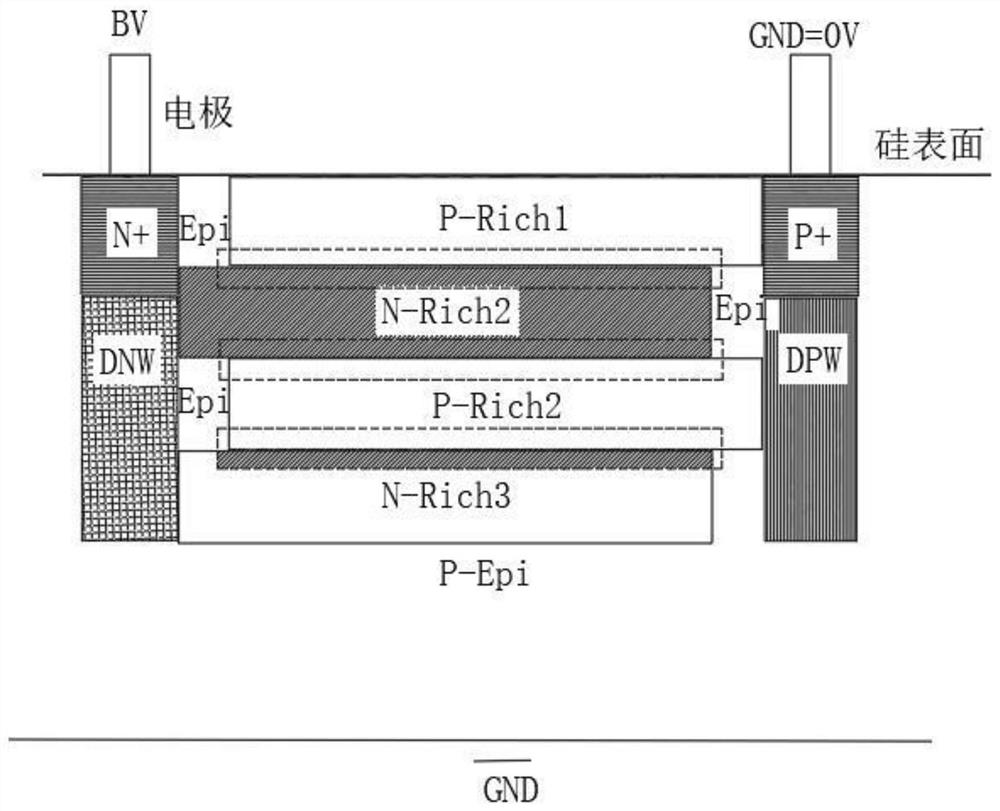

[0035] Such as figure 1 As shown, in the actual process, the silicon surface is directly in contact with silicon dioxide, which leads to the mismatch of the covalent bonds of the silicon atoms on the surface, thus generating a large amount of dark current, which makes the SPAD prone to breakdown even in the absence of light. , that is, the dark count rate is very high. This example adopts a surface P-type doped structure; this structure forms a P-N-P-N type space doping structure. Since the silicon surface is filled with P-type doping, the broken dangling bonds of silicon are replaced by P-type Impurities are trapped, thereby reducing dark current.

specific Embodiment 2

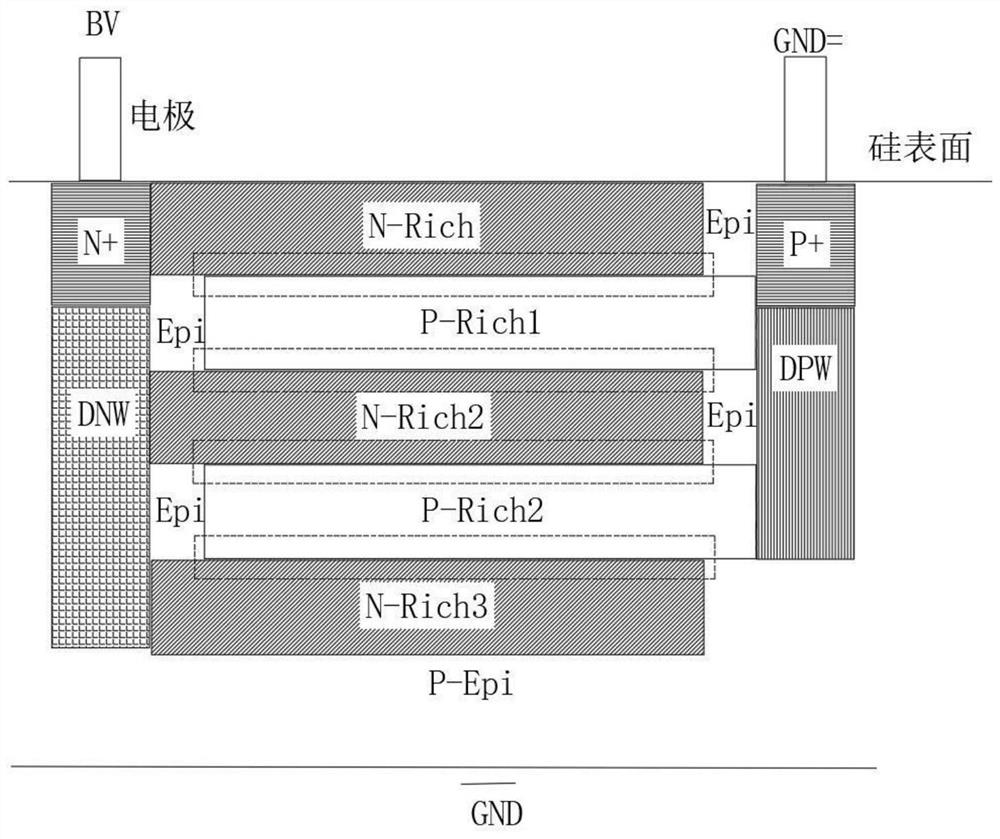

[0037] Such as figure 2 As shown, in the above application, P-EPI is used for isolation. Low-concentration doped PN structure isolation makes the width of the depletion region wider, which is not conducive to reducing the size of SPAD. In this example, N-type impurities and P-type impurities are used for isolation. Among them, the doping concentration of N-type impurities is lower than that of N-rich, and the doping of P-type impurities is lower than that of P-rich. The concentrations of N-type impurities and P-type impurities are higher than the concentration of P-type epitaxial layer p-epid At the same time, the silicon surface is separated by STI by digging grooves; wherein, in this specific embodiment, N-type adopts phosphorus, P-type adopts boron implantation, the first layer of N-type impurity implantation layer N-rich1, and the second layer of N-type impurity implantation layer The energies of N-rich2 and the third N-type impurity implanted layer N-rich3 are: 40KeV, 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com