Continuous feed of antistatic agent for gas phase polymerization process

An antistatic agent and antistatic technology, applied in the field of continuous feeding of antistatic agents used in the gas phase polymerization process, can solve problems affecting the activity of olefin polymerization catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

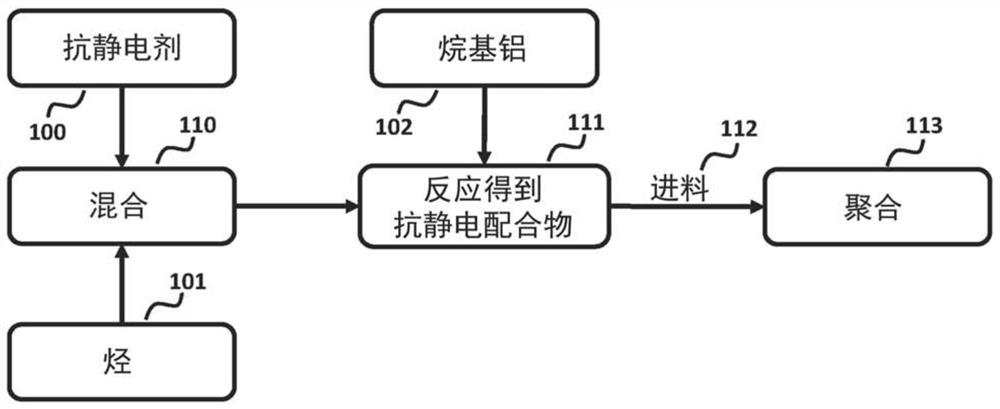

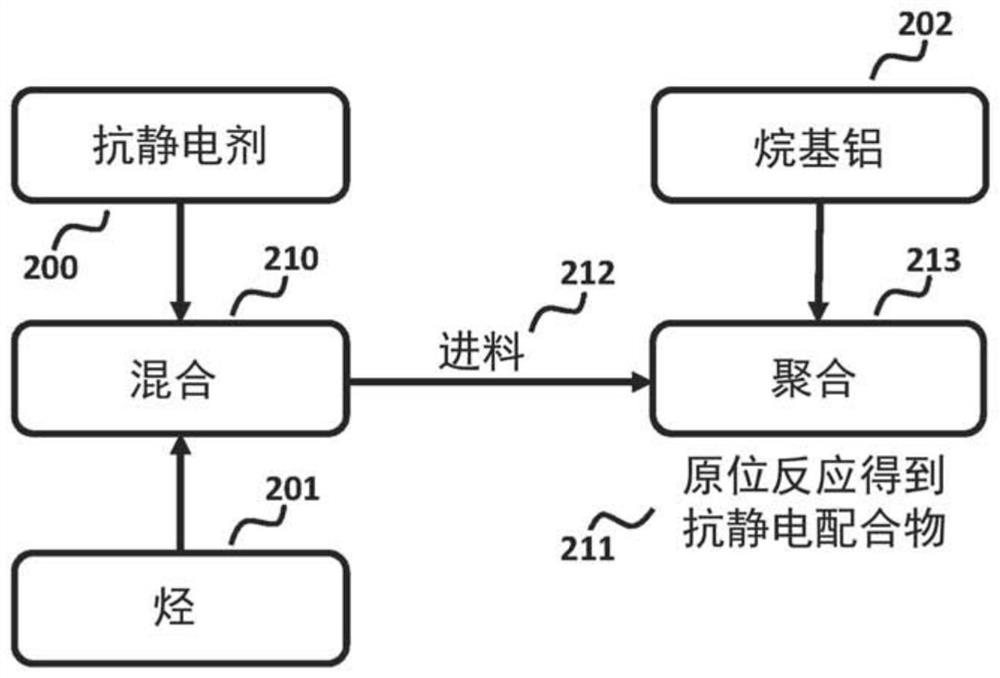

Method used

Image

Examples

Embodiment 1

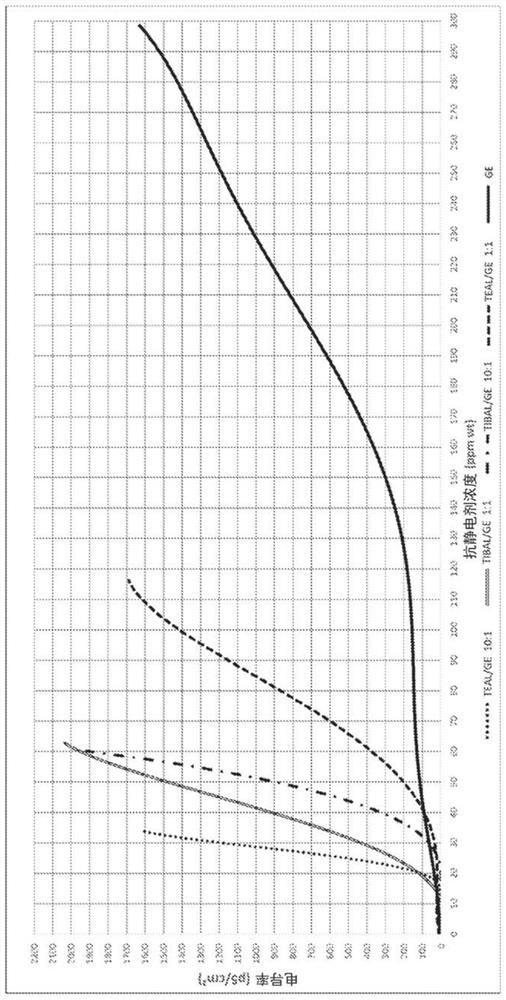

[0058] The electrical conductivity of a compound is an important property that determines whether a compound can be successfully used as an antistatic agent (or antistatic compound) during polymerization and whether it can compensate for electrostatic charges generated during polymerization. Grindsted PS 432 (Dupont) (referred to herein as "GE") and Triethylaluminum / Grindsted PS432 in ratios of both 1:1 and 10:1 mol / mol were measured using a Digital Conductivity Meter Model 1152 supplied by EMCEE Electronics (TEAL / GE) and the conductivity of mixtures of triisobutylaluminum / Grindsted PS432 (TIBAL / GE).

[0059] GE consists of two main substances: monoester of oleic acid with oxybis(propylene glycol) (CAS No. 49553-76-6); and acetate of monoglyceride (CAS No. 736150-63-3).

[0060] pass 1 H NMR (Agilent 400Mhz, with a DD2 console equipped with a OneNMR probe) studies the complexes of oleic acid monoester with oxybis(propylene glycol) / triisobutylaluminum or oxybis(propylene glyco...

Embodiment 2

[0067] In a fluidized bed gas phase reactor, by using Ziegler-Natta catalyst, triethyl-aluminum (TEAL) as a cocatalyst and cyclohexyl-methyl-dimethoxysilane as an external donor, the In the presence of hydrogen as molecular weight regulator, butene as density regulator, C3-C6 saturated hydrocarbon as inert diluent and Atmer 163 (ethoxylated amine) as antistatic agent, 36 kg / h of high-density polyethylene (HDPE). In the fluidized bed gas phase reactor, the operating conditions in Table 1 are met.

[0068] Table 1: Conditions of Example 2

[0069]

[0070] The total amount of Atmer 163 introduced in the polymerization reactor was 930 ppm by weight based on productivity.

[0071] The resulting HDPE had a melt flow index at 190°C of 12.0 (g / 10 min) and a density at 23°C of 0.952 g / cc. During this polymerization run, a continuous discharge of HDPE was observed and the formation of lumps was prevented.

Embodiment 3

[0073] The high density polyethylene was repeated according to the similar operating conditions of Example 2 to evaluate Grindsted PS432 (acetate ester of monoester / monoglyceride of oleic acid and oxybis(propylene glycol)).

[0074] In a fluidized bed gas phase reactor, by using Ziegler-Natta catalyst, triethyl-aluminum (TEAL) as a cocatalyst and cyclohexyl-methyl-dimethoxysilane as an external donor, the Hydrogen as molecular weight regulator, butene as density regulator, C3-C6 saturated hydrocarbon as inert diluent and Grindsted PS432 (monoester / monoglyceride of oleic acid and oxybis(propylene glycol)) as antistatic agent In the presence of acetate), ethylene is polymerized to produce 36 kg / h of high density polyethylene (HDPE). In the fluidized bed gas phase reactor, the operating conditions of Table 2 are satisfied:

[0075] Table 2: Conditions of Example 3

[0076]

[0077] The total amount of Grindsted PS432 introduced into the polymerization reactor was 650 ppm by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com