Method and equipment for eliminating white smoke of desulfurized flue gas

A flue gas and whitening technology, applied in the field of flue gas whitening, can solve the problems of increasing energy consumption, reducing energy utilization rate, and poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

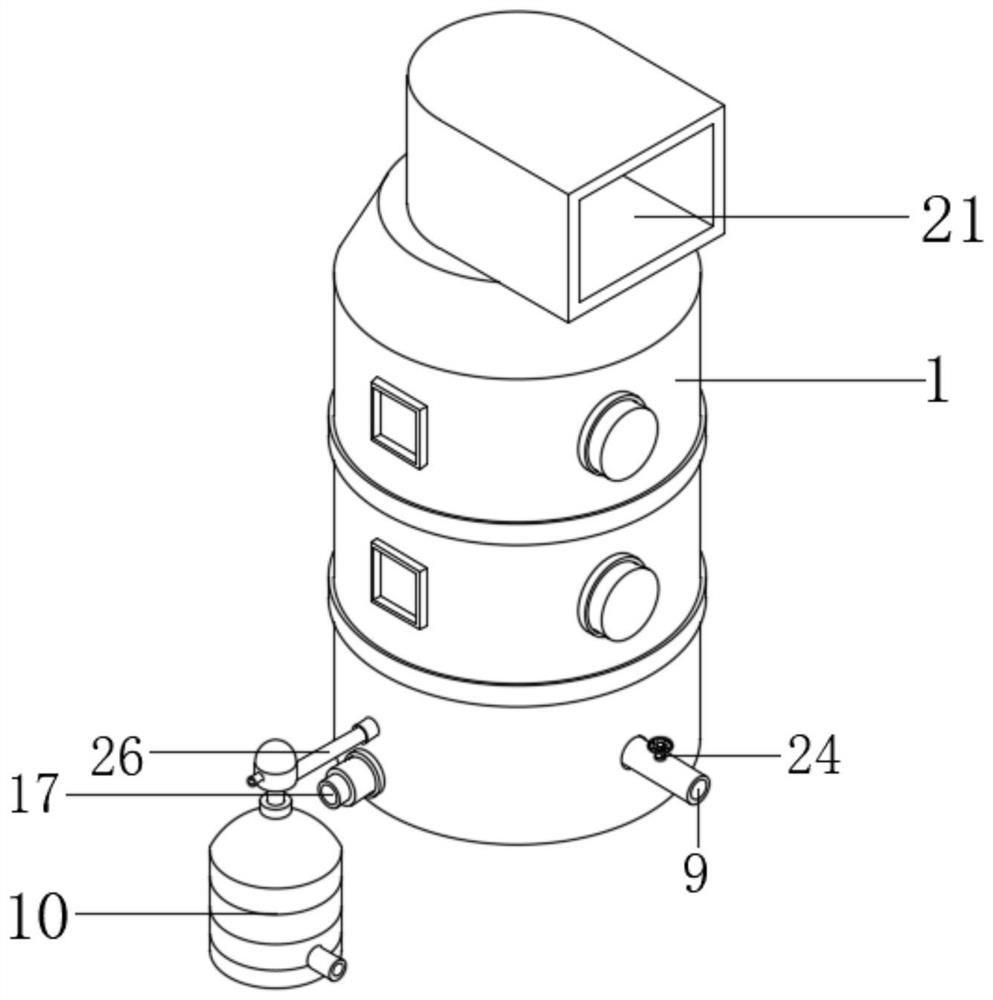

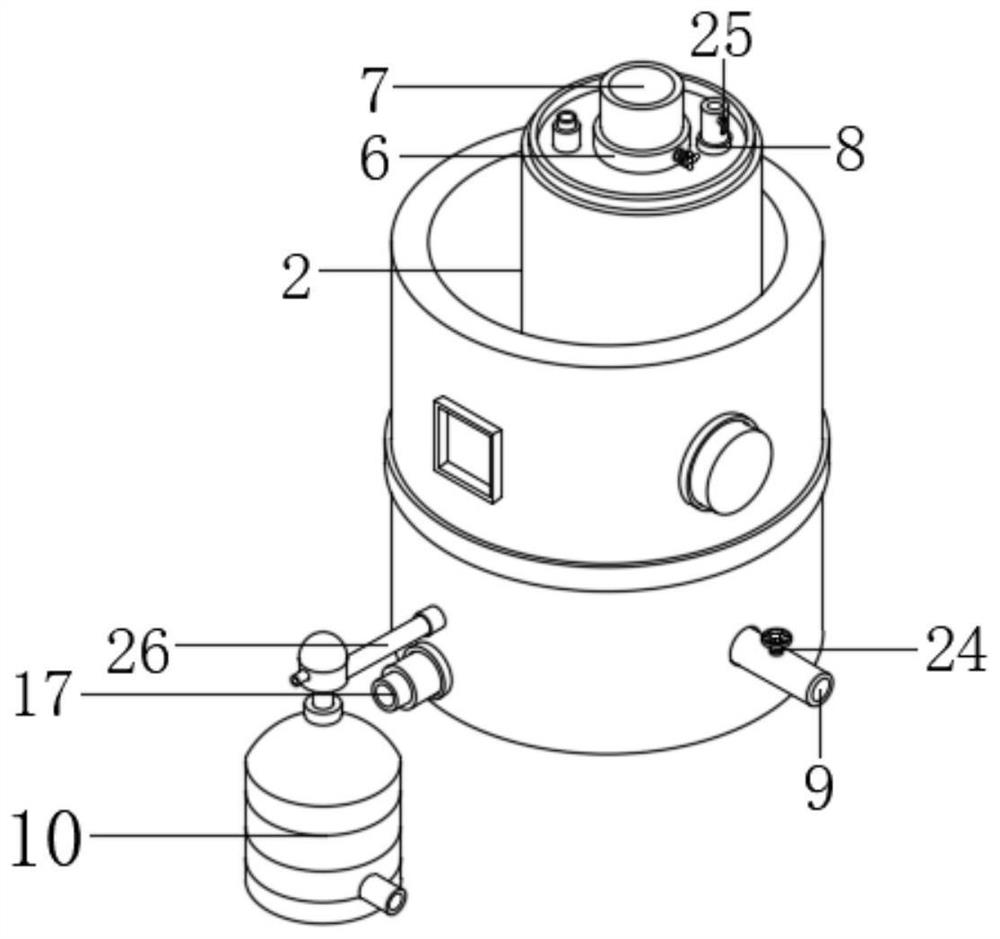

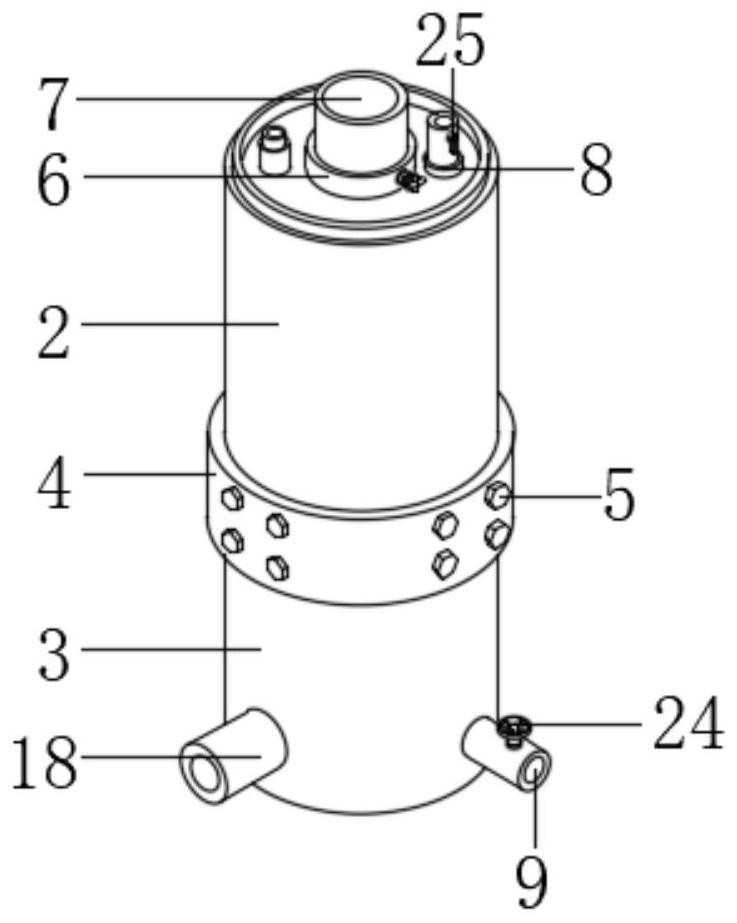

[0075] A method for desulfurization flue gas whitening, the method comprises the following steps:

[0076] S1, desulfurization treatment:

[0077] (1) Use desulfurization tower atomization desulfurization and dust removal treatment;

[0078] (2) The internal equipment of the desulfurization tower is a solid spray washing room, a condensation atomization washing room, a circulating fluidized filter room, a mass transfer washing room, and a dehydration and demisting room;

[0079] S2, whitening treatment:

[0080] (1) Use demisting facilities, spraying layers, ultra-clean facilities and heat exchange devices for whitening treatment of flue gas;

[0081] (2) Demisting facilities remove excess water mist and smoke in the flue gas;

[0082] (3) The spray layer further lowers the temperature of the flue gas;

[0083] (4) The flue gas of ultra-clean facilities is further treated for water mist and smoke removal;

[0084] (5) The heat exchange device heats the flue gas;

[0085]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com