Method for removing sludge odor through cooperation of metal salt and tannin extract, deodorized sludge and application of deodorized sludge

A metal salt and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as ignorance of tannin extract, improve dehydration and drying performance, and reduce biological Utilization, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

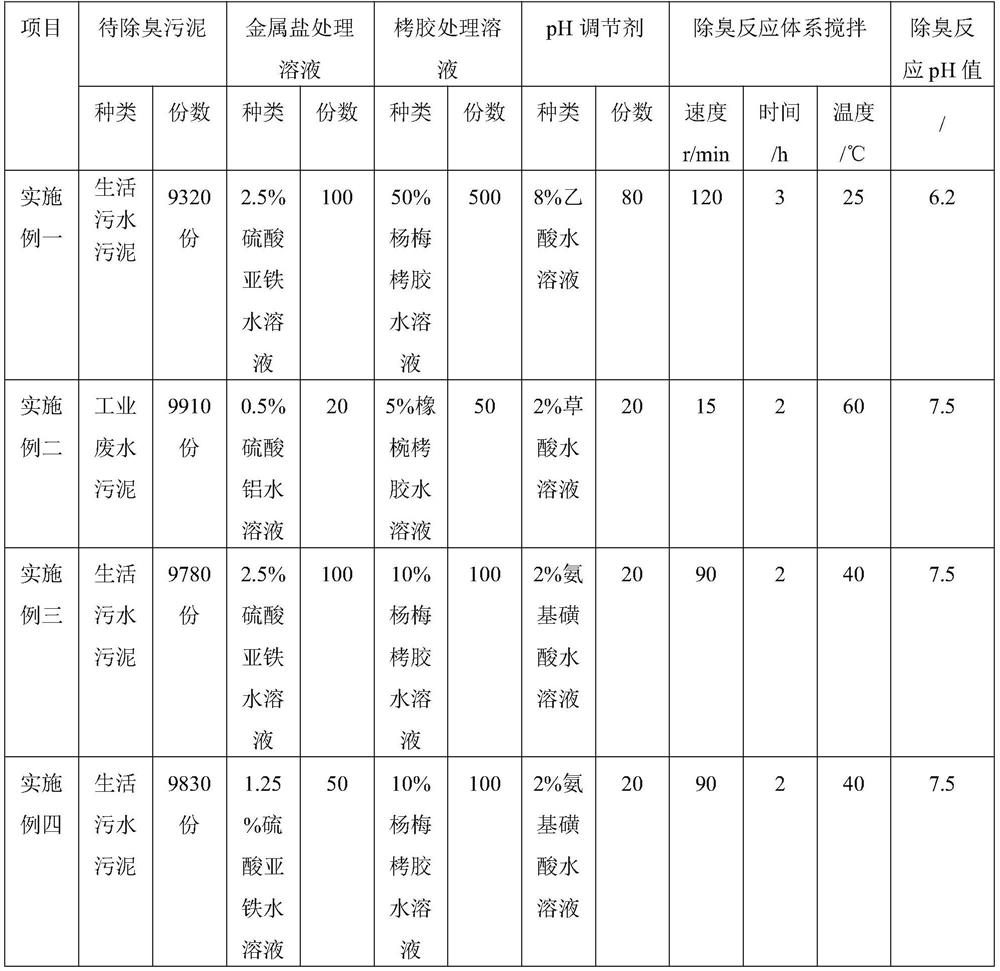

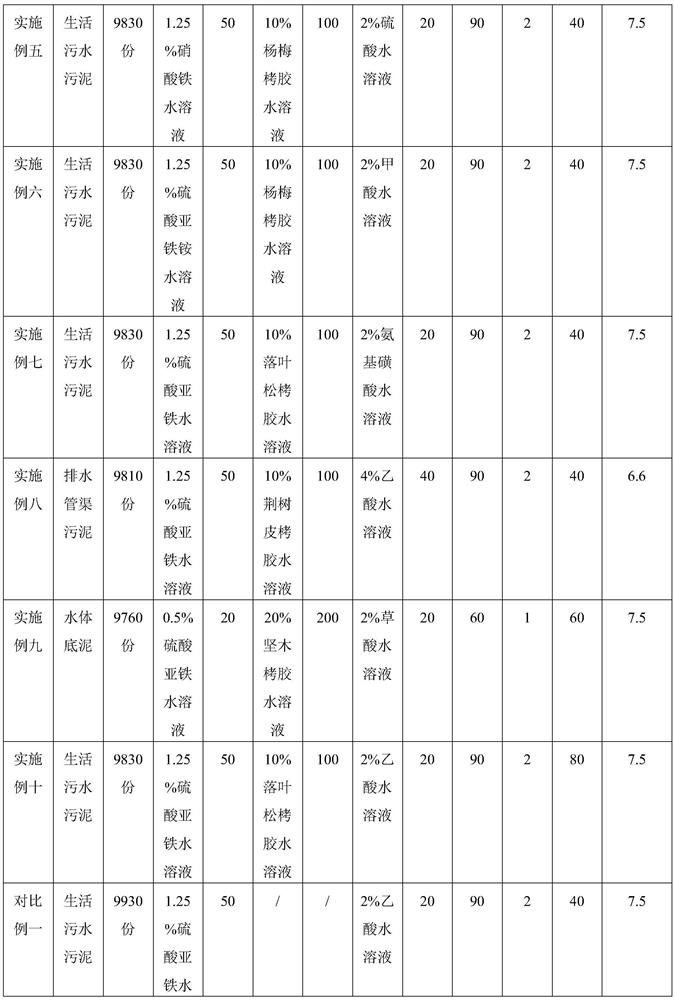

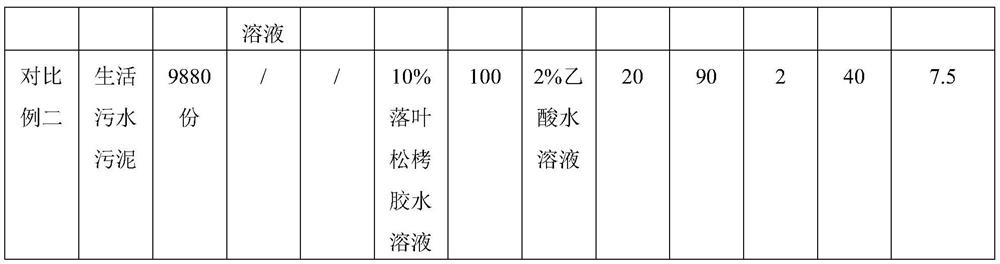

Embodiment 1

[0038] This embodiment provides a method for metal salts to cooperate with tannin extract to remove sludge odor, which includes the following specific steps:

[0039] First, put 9320 parts of deodorized sludge from domestic sewage into the stirring device, control the reaction temperature at 25°C, then add 100 parts of metal salt treatment solution, turn on the stirrer and stir for 1 hour at a speed of 120r / min to make it well mixed. Then mix 500 parts of tannin extract treatment solution with 80 parts of pH regulator and add it into the stirring device, control the pH to 6.2 and stir at a speed of 120r / min for 3 hours, and after standing for 12 hours, the odor in the sludge can be effectively removed . In this embodiment, the metal salt treatment solution is an aqueous solution of ferrous sulfate with a mass percentage of 2.5%, the tannin extract treatment solution is an aqueous solution of bayberry extract with a mass percentage of 50%, and the pH regulator is a mass percen...

Embodiment 2

[0041] This embodiment provides a method for metal salts to cooperate with tannin extract to remove sludge odor, which includes the following specific steps:

[0042] First, put 9910 parts of deodorized sludge from industrial wastewater into the stirring device, control the reaction temperature at 60°C, then add 20 parts of metal salt treatment solution, turn on the stirrer and stir at a speed of 15r / min for 1h to make it well mixed. Then mix 50 parts of tannin extract treatment solution with 20 parts of pH regulator and add it into the stirring device, control the pH to 7.5 and stir at a speed of 15r / min for 2 hours, after standing for 12 hours, the odor in the sludge can be effectively removed . In this embodiment, the metal salt treatment solution is an aqueous aluminum sulfate solution with a mass percentage of 0.5%, the tannin extract treatment solution is an aqueous solution of bayberry extract with a mass percentage of 5%, and the pH regulator is a mass percentage of ...

Embodiment 3

[0044] This embodiment provides a method for metal salts to cooperate with tannin extract to remove sludge odor, which includes the following specific steps:

[0045] First put 9780 parts of deodorized sludge from urban sewage treatment plants into the stirring device, control the reaction temperature at 40°C, then add 100 parts of metal salt treatment solution, turn on the stirrer and stir at a speed of 90r / min for 1h, Mix it well. Then mix 100 parts of tannin extract treatment solution with 20 parts of pH regulator and add it into the stirring device, control the pH to 7.5 and stir at a speed of 90r / min for 2 hours, after standing for 12 hours, the odor in the sludge can be effectively removed . In this embodiment, the metal salt treatment solution is an aqueous solution of ferrous sulfate with a mass percentage of 2.5%, the tannin extract treatment solution is an aqueous solution of bayberry extract with a mass percentage of 10%, and the pH regulator is a mass percent It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com