Full-chain cold-state preparation method of asphalt-based coating material

A coating material and asphalt-based technology, which is applied in the field of full-chain cold state preparation of asphalt-based coating materials, can solve the problems of poor environmental protection, poor wear resistance and high operating environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: Preparation of modified masterbatch.

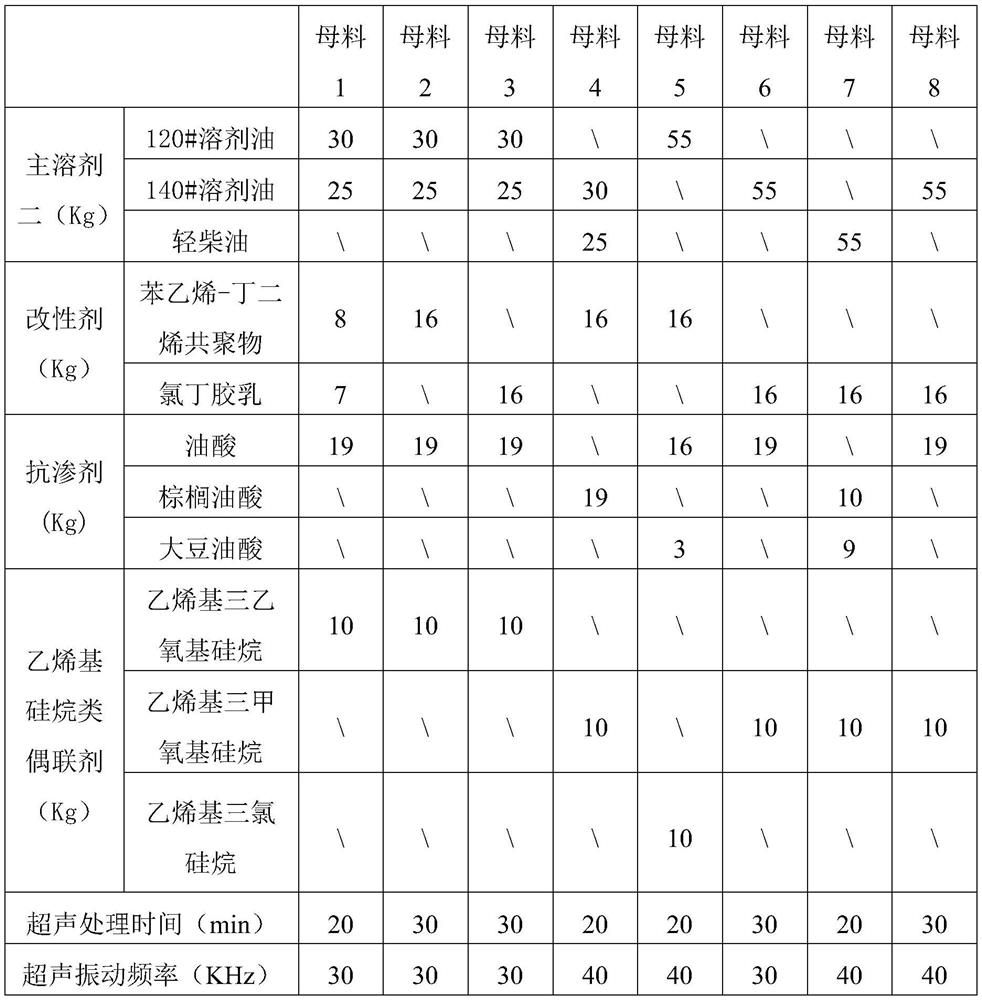

[0066] Table 2 Modified masterbatch material ratio and parameter control

[0067]

[0068] Material Description:

[0069] Oleic acid: molecular weight 282.46, melting point 13-14°C;

[0070] Palmitoleic acid: molecular weight 254.41, melting point 0.5°C;

[0071] Soybean oleic acid: 280≤molecular weight≤284, melting point 15℃.

[0072] 【Preparation】

[0073] Add the formula amount of main solvent 2 and anti-penetration agent into a small reaction kettle, stir at 30°C for 20 minutes to dissolve completely, then add silane coupling agent and modifier in turn, and shear and stir at 2500rpm for 40 minutes. After naturally cooling down to room temperature, ultrasonically treat for a certain period of time to obtain activated modified masterbatches, which are respectively recorded as masterbatch 1, masterbatch 2, masterbatch 3, masterbatch 4, masterbatch 5, masterbatch 6, masterbatch 7, masterbatch8. The whole proc...

Embodiment 2

[0074] Example 2: Preparation of anti-seepage long-acting durable asphalt pavement maintenance coating material.

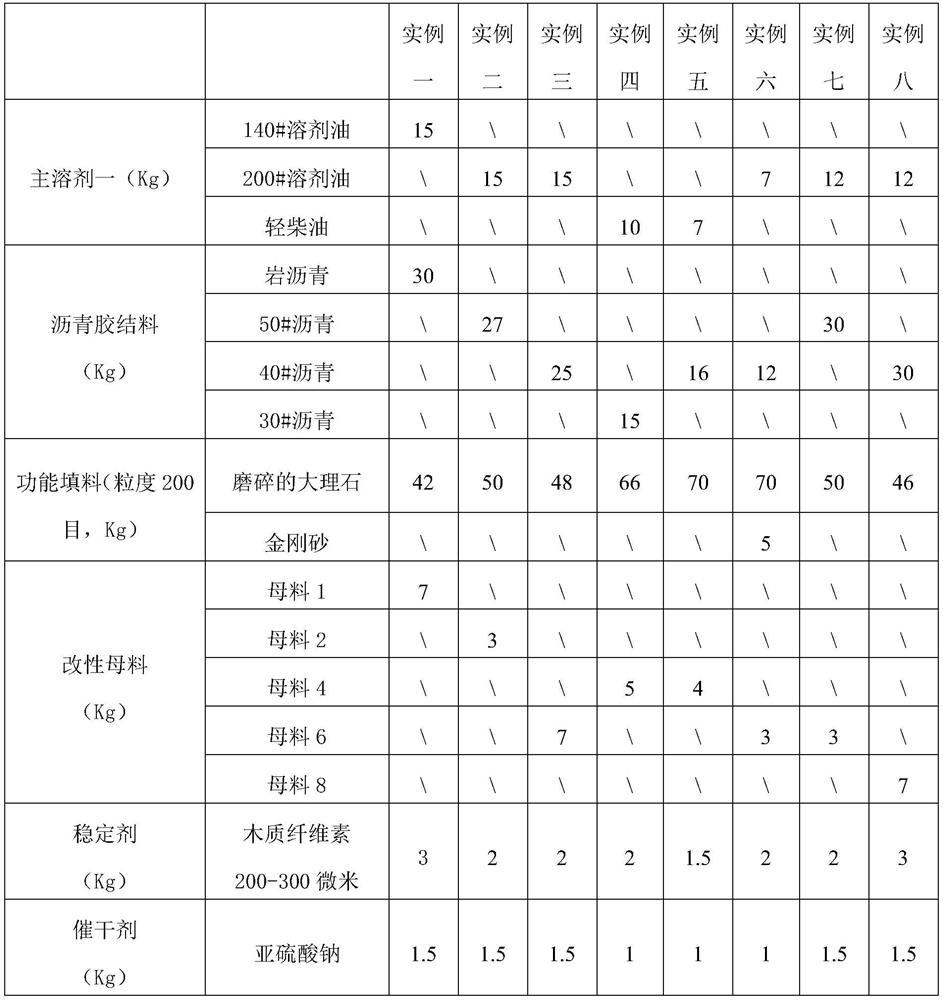

[0075] Table 3 Material ratio of coating materials

[0076]

[0077] Material Description:

[0078] Qingchuan Rock Asphalt: Penetration 3 (0.1mm) at 25°C, softening point 220°C;

[0079] 50# asphalt: at 25°C, the penetration is 45 (0.1mm), and the softening point is 67°C;

[0080] 40# asphalt: at 25°C, the penetration is 38 (0.1mm), and the softening point is 70°C;

[0081] 30# asphalt: at 25°C, the penetration is 28 (0.1mm), and the softening point is 72°C;

[0082] 【Preparation】

[0083] A1. Using the liquid nitrogen quick-freezing process, the asphalt binder is frozen and solidified at 20°C below the brittle point of the asphalt, and sent to the ball mill crushing equipment. At the same time, functional fillers are added in proportion for synchronous crushing and grinding. The crushing specification is controlled to be no less than 200 To obtain compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com