Ionization type gas sensor and preparation method thereof

A gas sensor and ionization technology, applied in instruments, scientific instruments, and material analysis through electromagnetic means, can solve the problems of high-density current oxidation and degradation of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

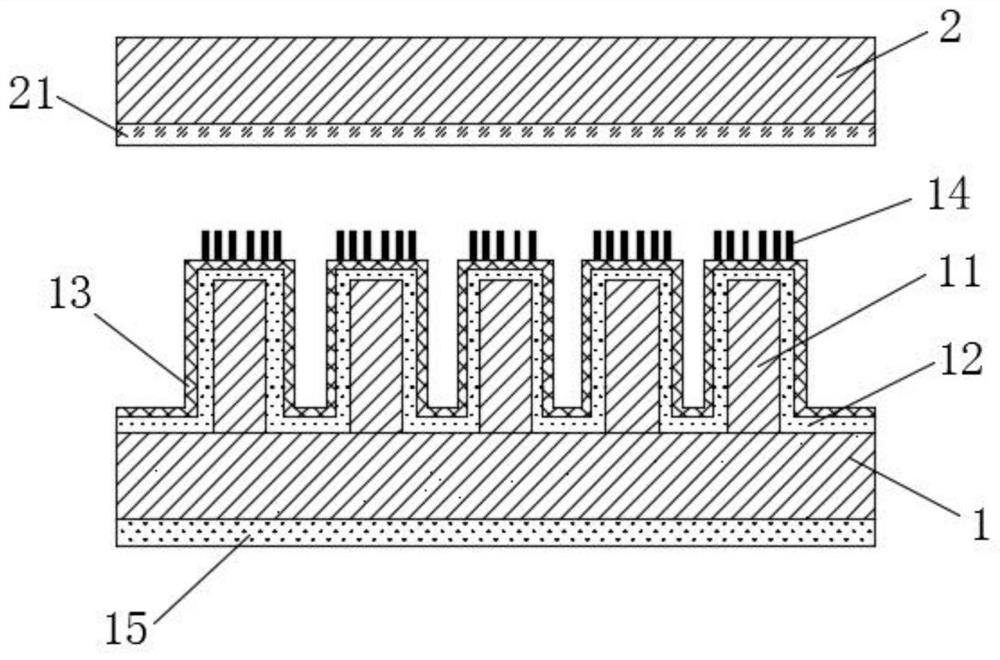

[0041] An ionization gas sensor, comprising a first electrode plate 1 and a second electrode plate 2, the material of the first electrode plate 1 is a silicon wafer, and a layer of conductive metal is sputtered on the side of the first electrode plate 1 away from the second electrode plate 2 Thin film 15, the material of conductive metal thin film 15 is gold; The second electrode plate 2 is a planar electrode;

[0042]The electrode array 11 is provided on the side of the first electrode plate 1 facing the second electrode plate 2 , and a layer of copper film 13 is provided on the upper surface of the electrode array 11 , and the thickness of the copper film 13 is 620 nm. The upper surface of the copper film 13 is provided with metal oxide nanowires 14, and the metal oxide nanowires 14 are CuO nanowires.

[0043] A preparation method of an ionized gas sensor, the method steps are as follows:

[0044] S1: Sputter a layer of uniform conductive metal film on the side of the silic...

Embodiment 2

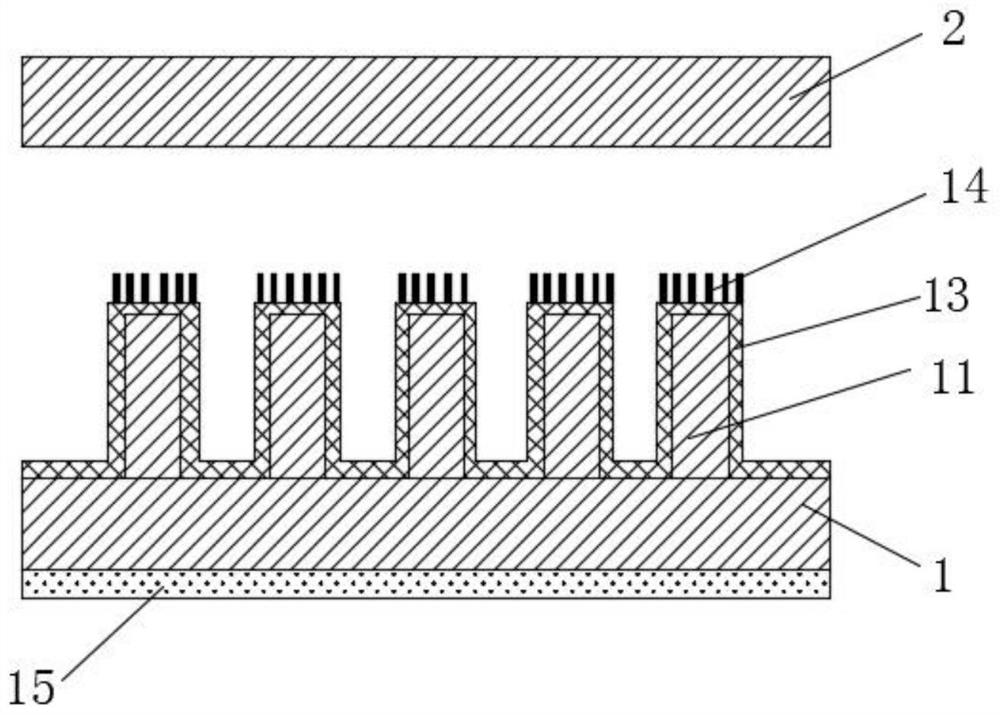

[0051] An ionization gas sensor, comprising a first electrode plate 1 and a second electrode plate 2, the material of the first electrode plate 1 is a silicon wafer, and a layer of conductive metal is sputtered on the side of the first electrode plate 1 away from the second electrode plate 2 Thin film 15, the material of conductive metal thin film 15 is gold; The second electrode plate 2 is a planar electrode;

[0052] An electrode array 11 is provided on the side of the first electrode plate 1 facing the second electrode plate 2 , and a layer of copper film 13 is provided on the upper surface of the electrode array 11 ; the thickness of the copper film 13 is 620 nm.

[0053] The upper surface of the copper film 13 is provided with metal oxide nanowires 14, and the metal oxide nanowires 14 are CuO nanowires; the second electrode plate 2 is sputtered with an electrode film 21 facing the side of the first electrode plate 1. The material is molybdenum.

[0054] A preparation met...

Embodiment 3

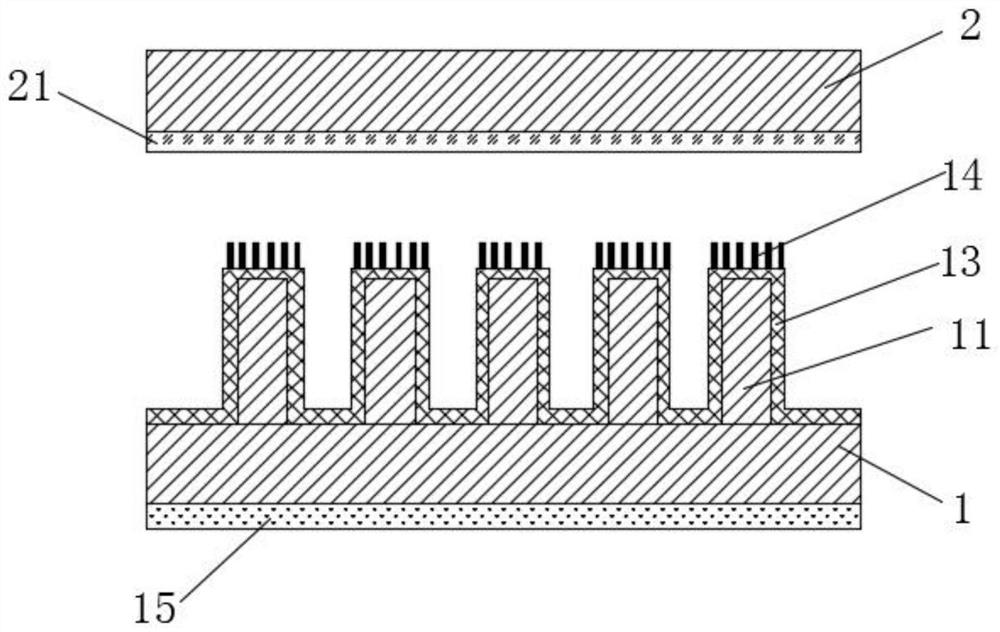

[0063] An ionization gas sensor, comprising a first electrode plate 1 and a second electrode plate 2, the material of the first electrode plate 1 is a silicon wafer, and a layer of conductive metal is sputtered on the side of the first electrode plate 1 away from the second electrode plate 2 Film 15, the material of conductive metal film 15 is silver; the second electrode plate 2 is a plane electrode;

[0064] The electrode array 11 is provided on the side of the first electrode plate 1 facing the second electrode plate 2 , and a layer of copper film 13 is provided on the upper surface of the electrode array 11 , and the thickness of the copper film 13 is 620 nm.

[0065] The upper surface of the copper film 13 is provided with metal oxide nanowires 14, and the metal oxide nanowires 14 are CuO nanowires; the second electrode plate 2 is sputtered with an electrode film 21 facing the side of the first electrode plate 1. The material is chrome.

[0066] A preparation method of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com