Preparation method of neodymium-iron-boron magnet with large-depth grain boundary diffusion

A technology of grain boundary diffusion and NdFeB, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of shallow depth of grain boundary diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a large depth grain boundary diffuse NdFeB magnet, including the following steps:

[0024] Step 1, select the NICE iron magnet of the commercial grade N52, cut N52 magnets into 10 × 10 × 5 (c-axis) mm 3 The surface oxide layer was placed with sandpaper, and clean with acetone.

[0025] Step 2, the magnet produced by steps is immersed in liquid nitrogen in -196 ° C for 20 minutes;

[0026] Step three, the magnet processed by step deeper is taken out from liquid nitrogen to increase the temperature of the magnet to room temperature;

[0027] Step 4, repeat steps 2 and step three 3 times;

[0028] Step 5. The magnet surface after step four is applied to the low melting point alloy DY. 70 Cu 30 Powder, put it in a vacuum furnace to 1 × 10 -2 PA, then elevated temperature to 800 ° C, heat insulation 1H;

[0029] Step 6. The magnet after the diffusion process in step five is lowered at 450 ° C for 2 hours, and the vacuum is set to 1 × 10 -2 PA.

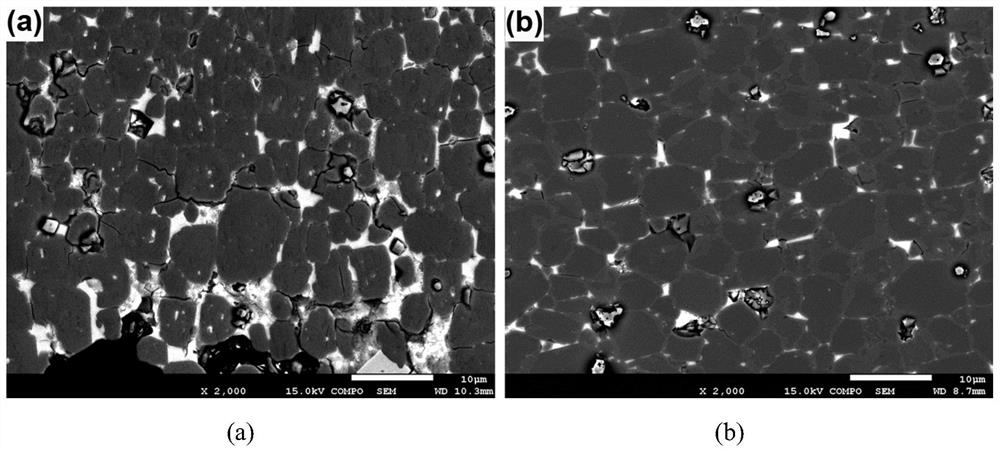

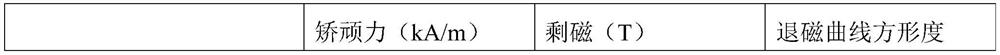

Embodiment 2

[0038] A method for preparing a large depth grain boundary diffuse NdFeB magnet, including the following steps:

[0039] Step 1, select the sintered NdFeB magnet of the commercial grade N52, cut N52 magnets into 10 × 10 × 15 (c-axis) mm 3 The surface oxide layer was placed with sandpaper, and clean with acetone.

[0040] Step 2, the magnet produced by the step is immersed in liquid nitrogen in liquid nitrogen for 40 minutes;

[0041] Step three, the magnet processed by step deeper is taken out from liquid nitrogen to increase the temperature of the magnet to room temperature;

[0042] Step four, repeat steps 2 and steps three 4 times;

[0043] Step 5, the magnet surface is applied to the surface of the magnet surface to apply low melting point alloy TB 70 Cu 30 Powder, put it in a vacuum furnace to 1 × 10 -3 PA, then elevated temperature to 900 ° C, heat insulation 10h;

[0044] Step 6. The magnet after the step five diffusion is lowered at 480 ° C for 1 h, and the vacuum is set t...

Embodiment 3

[0054] A method for preparing a large depth grain boundary diffuse NdFeB magnet, including the following steps:

[0055] Step 1, select the sintered NdFeB magnet of the commercial grade N52, cut N52 magnets into 10 × 10 × 10 (c-axis) mm 3 The surface oxide layer was placed with sandpaper, and clean with acetone.

[0056] Step 2, the magnets formed by the steps were immersed in liquid nitrogen in liquid nitrogen in liquid nitrogen for 30 minutes;

[0057] Step three, the magnet processed by step deeper is taken out from liquid nitrogen to increase the temperature of the magnet to room temperature;

[0058] Step 4, repeat steps 2 and step three 5 times;

[0059] Step 5, the magnet surface after step four is applied to the low melting point alloy DYF 3 Powder, put it in a vacuum furnace to 1 × 10 -3 PA, then elevated temperatures to 950 ° C, heat insulation 5h;

[0060] Step 6, the magnet after the diffusion process in step five is lowered at 520 ° C for 6 hours, and the vacuum is se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com