GaN-based HEMT device based on substrate conductive hole and preparation method of GaN-based HEMT device

A conductive hole and substrate technology, which is applied in the field of GaN-based HEMT devices based on substrate conductive holes and its preparation, can solve the problems of high manufacturing and equipment costs and lower yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

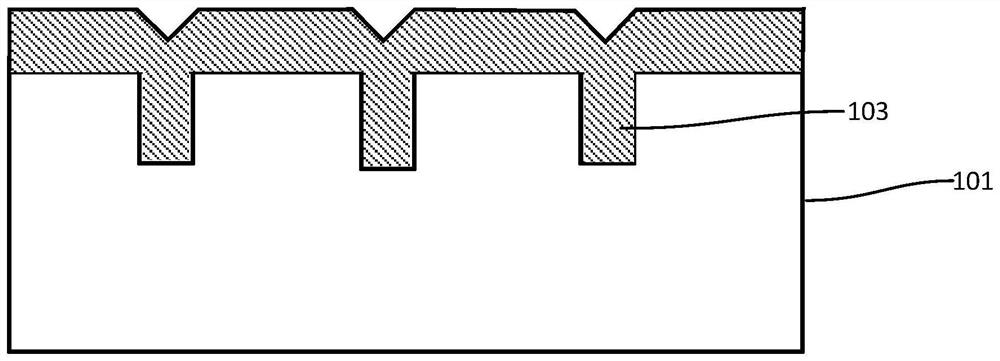

[0055] Such as Figure 1 to Figure 10 As shown, this embodiment provides a method for preparing a GaN-based HEMT device based on substrate conductive holes. The device may be a radio frequency device, for example. The preparation method includes the steps of:

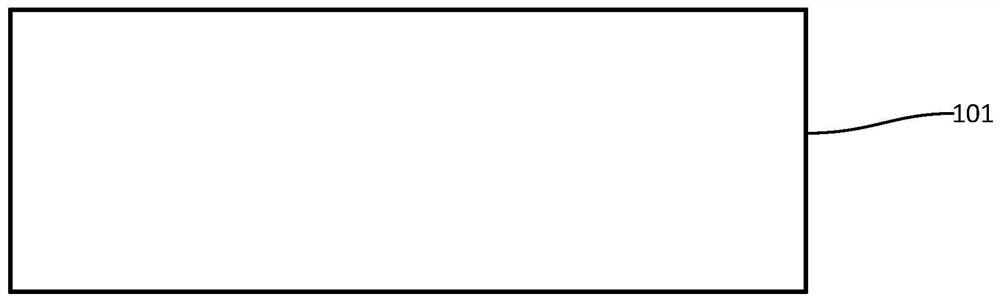

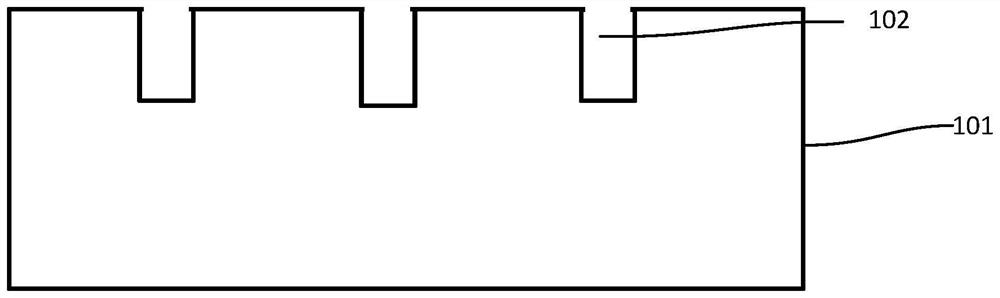

[0056] Such as Figure 1 ~ Figure 2 As shown, step 1) is first performed to provide a substrate 101, the substrate 101 includes a first main surface and a second main surface opposite, and a deep groove is etched in the first main surface of the substrate 101 Groove 102, the deep trench 102 is set corresponding to the source of the GaN-based HEMT device.

[0057] As an example, the substrate 101 includes one of a silicon-based substrate, a silicon carbide substrate, a gallium nitride substrate, a sapphire substrate, and a diamond substrate. In this embodiment, the substrate 101 is selected as a semi-insulating silicon substrate, which is used as the substrate required for the growth of the epitaxial layer structure of ...

Embodiment 2

[0078] Such as Figure 11 As shown, this embodiment provides a GaN-based HEMT device and its preparation method, the basic steps and basic structure of which are as in Embodiment 1, wherein the difference from Embodiment 1 lies in: the sidewall of the deep trench and the A diffusion barrier layer 201 is also formed between the conductive material layers, and the diffusion barrier layer 201 includes SiO 2 , SiN, Al 2 o 3 , AlN, HfO 2 A stacked structure of one or more of them is used to prevent dopant elements in the conductive silicon layer from diffusing into the substrate, so as to improve the electrical stability of the device.

Embodiment 3

[0080] Such as Figure 12 As shown, this embodiment provides a GaN-based HEMT device and its preparation method, its basic steps and basic structure are as in Embodiment 1, wherein, the difference from Embodiment 1 lies in that each source metal is connected to a corresponding source There are multiple ultra-deep holes 110 and connection layers 111 to reduce the width of the source deep holes, so that the connection layer 111, such as a conductive silicon layer, can more easily fill the source deep holes 110, improving the efficiency and process stability of the manufacturing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com