Heteropolyacid composite catalyst material H3PW12O40/PAN as well as preparation method and application thereof

A technology of H3PW12O40 and composite catalyst, which is applied in the field of environmental engineering, can solve the problems of low recycling rate and achieve the effects of fast reaction rate, reduced processing energy consumption, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

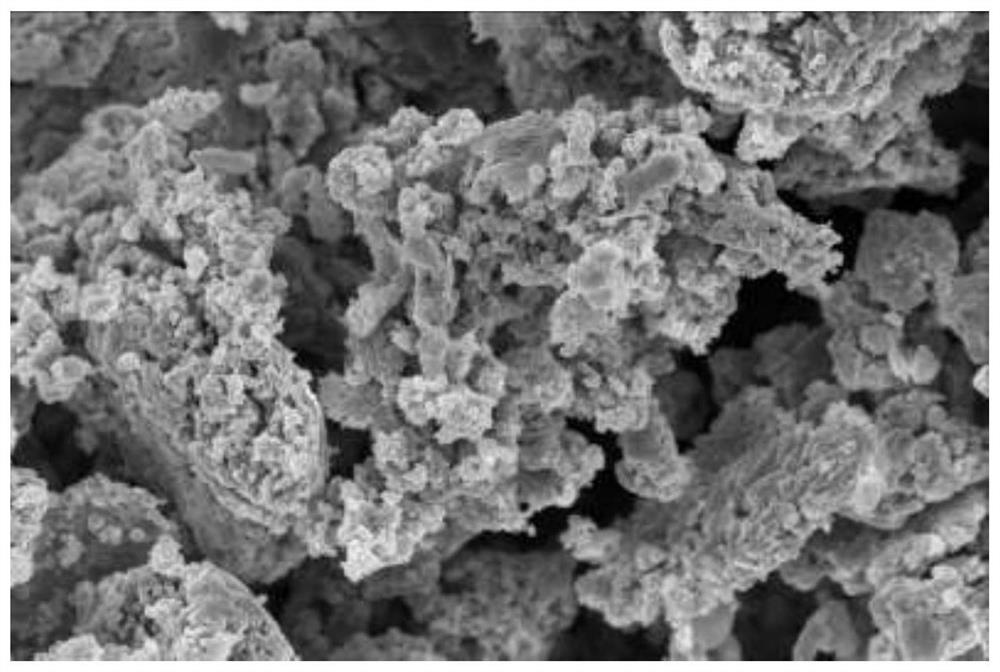

Image

Examples

Embodiment 1

[0029] 1) Synthesis of polyaniline: Take aniline solution and add it to 0.1mol / L dilute HCl, the volume ratio of aniline and hydrochloric acid is 1:600, prepare mixed solution 1, dissolve ammonium persulfate in 0.1mol / L dilute HCl , wherein the mass volume ratio of ammonium persulfate and hydrochloric acid is 1:40g / ml, prepare mixed solution 2, refrigerate at 5°C for 20min, slowly add mixed solution 2 to mixed solution 1, and the solution dropping rate is 20ml / h, Magnetic stirring in an ice bath during the dropwise addition, and magnetic stirring at room temperature for 24 hours after the dropwise addition. After the stirring, the polyaniline was washed with water and methanol alternately for 4 times until neutral, then dried in vacuum, and the polyaniline was collected for future use.

[0030] 2) Catalyst synthesis: Mix phosphotungstic acid and polyaniline at a certain mass ratio of 1:0.5, then mix the mixture with methanol at a ratio of 1:15g / ml, heat to reflux under magneti...

Embodiment 2

[0033]1) Synthesis of polyaniline: Take aniline solution and add it to 0.1mol / L dilute HCl, the volume ratio of aniline and hydrochloric acid is 1:400, prepare mixed solution 1, dissolve ammonium persulfate in 0.1mol / L dilute HCl , wherein the mass volume ratio of ammonium persulfate and hydrochloric acid is 1:30, prepare mixed solution 2, refrigerate at 5°C for 25 minutes, slowly add mixed solution 2 to mixed solution 1, the solution dropping rate is 30ml / h, drop Magnetic stirring in an ice bath during the process, and magnetic stirring at room temperature for 24 hours after the dropwise addition. After the stirring was completed, the polyaniline was washed with water and methanol alternately for 6 times until neutral, then dried in vacuum, and the polyaniline was collected for future use.

[0034] 2) Catalyst synthesis: mix phosphotungstic acid and polyaniline in a certain proportion, the mass ratio of phosphotungstic acid and polyaniline is 1:2, then mix the mixture with me...

Embodiment 3

[0037] 1) Synthesis of polyaniline: Take a certain amount of aniline solution and add it to 0.1mol / L dilute HCl, the volume ratio of aniline and hydrochloric acid is 1:800, prepare mixed solution 1, and dissolve ammonium persulfate in 0.1mol / L dilute HCl, wherein the mass volume ratio of ammonium persulfate and hydrochloric acid is 1:50g / ml, prepare mixed solution 2, refrigerate at 5°C for 45min, slowly add mixed solution 2 to mixed solution 1, and the solution dropping rate is 60ml / h, stirring magnetically in an ice bath during the dropwise addition, and magnetically stirring at room temperature for 24h after the dropwise addition. After the stirring was completed, the polyaniline was washed with water and methanol alternately for 3 times until neutral, then dried in vacuum, and the polyaniline was collected for future use.

[0038] 2) Catalyst synthesis: mix phosphotungstic acid and polyaniline in a certain proportion, the mass ratio of phosphotungstic acid to polyaniline i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com