Method for recycling iron-containing and zinc-containing solid waste

A technology for solid waste and iron powder, applied in recycling technology, mechanical material recovery, solid separation, etc., can solve the problems of low sorting efficiency, poor reference, poor product quality, etc., to improve the extraction rate and temperature. , the effect of saving development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

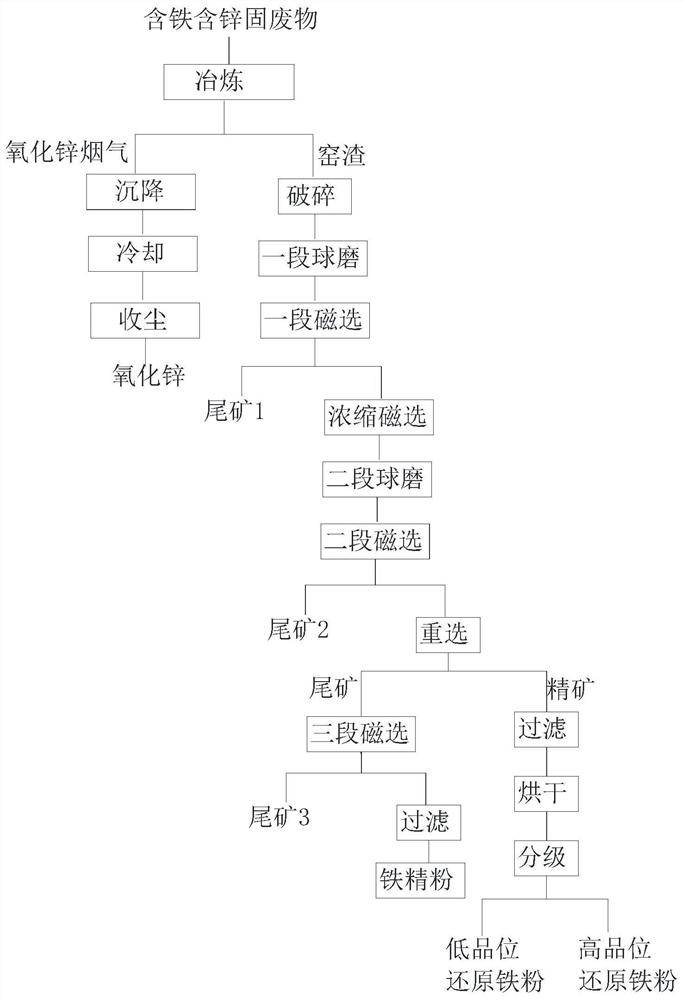

[0049] A method for recycling iron-containing and zinc-containing solid waste, its work flow is as follows figure 1 shown, including the following steps:

[0050]First, water vapor and air are sent into the rotary kiln at a volume ratio of 1:20, and the water vapor and air react with the anthracite to generate Zn steam, which can quickly increase the temperature of the rotary kiln to 1350-1500°C, and then The solid waste containing iron and zinc is sent to the rotary kiln for smelting to obtain zinc oxide flue gas and kiln slag; the zinc oxide flue gas is discharged from the rotary kiln and then settles in the settling chamber, cooled by the surface cooling equipment, and then dedusted by the bag dust removal system , to obtain zinc oxide, and the remaining flue gas enters the desulfurization system and then discharges up to the standard. The content of zinc oxide obtained in this example is 53%, which can provide zinc raw materials for electrolytic zinc plants.

[0051] Col...

Embodiment 2

[0057] A method for recycling iron-containing and zinc-containing solid waste, comprising the following steps:

[0058] First, water vapor and air are sent into the rotary kiln at a ratio of 1:15 by volume, and the water vapor and air react with the anthracite in it to generate Zn steam, which can quickly increase the temperature of the rotary kiln to 1350-1500°C, and then The solid waste containing iron and zinc is sent to the rotary kiln for smelting to obtain zinc oxide flue gas and kiln slag; the zinc oxide flue gas is discharged from the rotary kiln and then settles in the settling chamber, cooled by the surface cooling equipment, and then dedusted by the bag dust removal system , to obtain zinc oxide, and the remaining flue gas enters the desulfurization system and then discharges up to the standard. The content of zinc oxide obtained in this example is 50%, which can provide zinc raw materials for electrolytic zinc plants.

[0059] Collect the kiln slag in the rotary k...

Embodiment 3

[0065] A method for recycling iron-containing and zinc-containing solid waste, comprising the following steps:

[0066] First, water vapor and air are sent into the rotary kiln at a volume ratio of 1:25, and the water vapor and air react with the anthracite to generate Zn steam, which can quickly increase the temperature of the rotary kiln to 1350-1500°C, and then The solid waste containing iron and zinc is sent to the rotary kiln for smelting to obtain zinc oxide flue gas and kiln slag; the zinc oxide flue gas is discharged from the rotary kiln and then settles in the settling chamber, cooled by the surface cooling equipment, and then dedusted by the bag dust removal system , to obtain zinc oxide, and the remaining flue gas enters the desulfurization system and then discharges up to the standard. The content of zinc oxide obtained in this example is 54%, which can provide zinc raw materials for electrolytic zinc plants.

[0067] Collect the kiln slag in the rotary kiln, send...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com