Environment-friendly degradable kraft ink packaging bag and preparation method thereof

A technology of packaging bags and kraft paper, applied in packaging, wrapping paper, wrapping paper, etc., can solve the problems of ink residue, non-environmental protection, etc., and achieve the effects of reducing ink residue, ensuring quality and shelf life, and superior barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

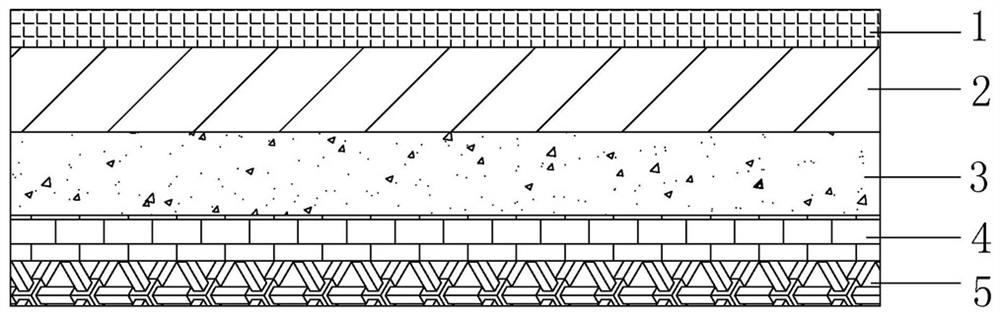

[0025] refer to figure 1 , an environmentally friendly degradable kraft paper ink packaging bag, which is composed of a transparent layer 1, a kraft paper layer 2, an adhesive layer 3, a barrier layer 4 and a hydrophobic and oleophobic layer 5 from outside to inside. Under the synergistic effect of the multi-layer structure, it has excellent barrier properties and can effectively block oxygen, water vapor, light, etc., ensuring the quality and shelf life of the ink, and reducing ink residue.

[0026] A kind of preparation method as above-mentioned packaging bag, its steps are as follows:

[0027] (1) Manufacture of composite materials: Place the film rolls of the transparent layer, kraft paper layer, adhesive layer and barrier layer on the hot roller press, so that the transparent layer, kraft paper layer, adhesive layer and barrier layer are sequentially arranged from top to bottom Lamination hot roll lamination, roll lamination to make composite materials and then winding. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com