Underfill glue for electronic packaging device, preparation method and electronic packaging device

An underfill, electronic packaging technology, used in semiconductor/solid-state device parts, electrical solid devices, electrical components, etc., can solve the problems of increased system viscosity, reduced impact resistance of underfills, uneven dispersion, etc. Thermal expansion coefficient, low thermal expansion coefficient, easy dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

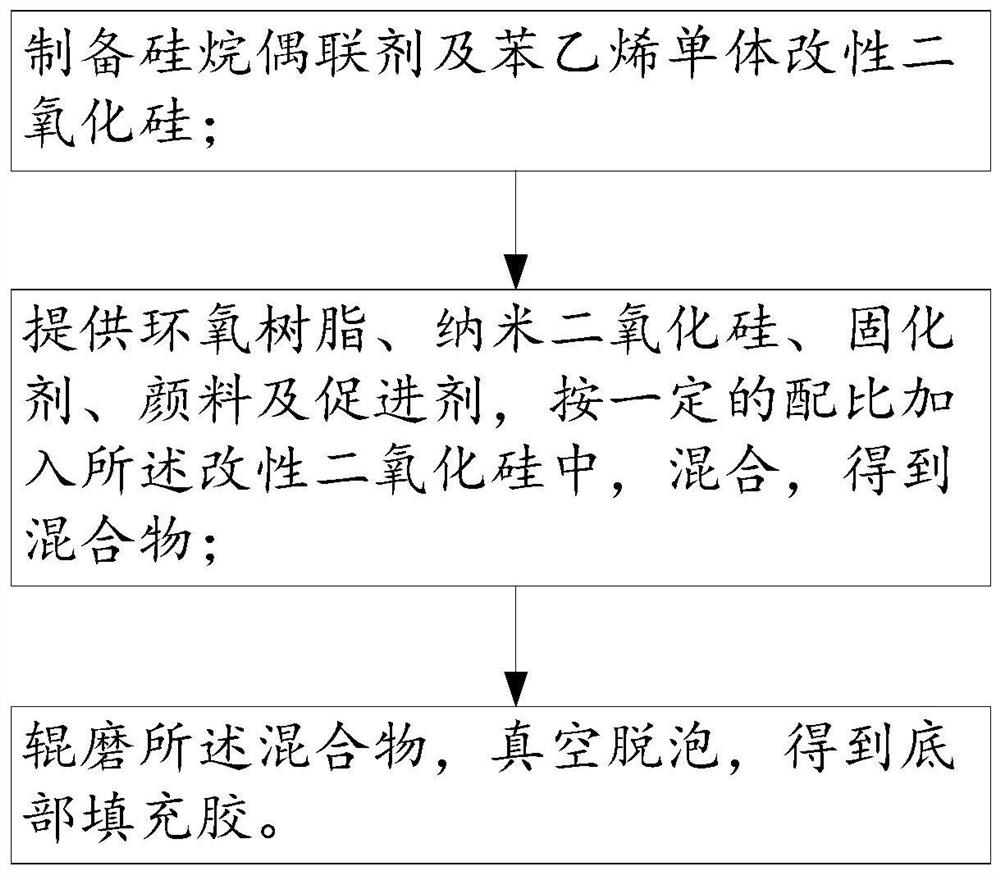

[0049] see figure 1 , the embodiment of the present application also provides a preparation method of an underfill for electronic packaging devices, comprising the following steps:

[0050] Step S1: preparing silane coupling agent and styrene monomer modified silica;

[0051] Step S2: providing epoxy resin, nano-silica, curing agent, pigment and accelerator, adding the silane coupling agent and styrene monomer modified silica in a certain proportion, and mixing to obtain a mixture; as well as

[0052] Step S3: Roll-milling the mixture and vacuum defoaming to obtain a low-expansion-coefficient underfill for electronic packaging devices.

[0053] In at least one embodiment, the step S1 is specifically:

[0054] Step S11: providing silica and adding it to the container;

[0055] Step S12: adding deionized water to the container, stirring and heating up to 70-90°C;

[0056] Step S13: add a silane coupling agent to the container, keep the temperature for a period of time T 1 ...

Embodiment 1

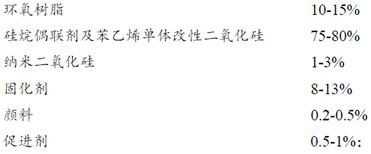

[0074] The underfill for electronic packaging devices in this embodiment is composed of the following raw materials by mass percentage:

[0075]

[0076] Wherein, the modified silica is obtained by the following method:

[0077] Weigh a certain weight of silica and add it to a four-necked flask, then add deionized water, stir and heat up to 80°C, then add γ-methacryloyloxypropyltrimethoxysilane, and keep the reaction for 12h to obtain modification Silica, wherein the mol ratio of silica to γ-methacryloyloxypropyltrimethoxysilane is 5:1;

[0078] A certain amount of styrene was slowly added dropwise at a rate of 2 drops per second. After the addition, the initiator ammonium persulfate was added dropwise, and the reaction was continued for 6 hours. The suspension was filtered and dried at a low temperature of 50 °C to obtain silane coupling agent and benzene. Ethylene monomer modified silica, wherein the molar ratio of modified silica, styrene and ammonium persulfate is 5:1:...

Embodiment 2

[0080] The underfill for electronic packaging devices in this embodiment is composed of the following raw materials by mass percentage:

[0081]

[0082] Wherein, the preparation method of the modified silica is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com