Preparation method of SOD (superoxide dismutase) white spirit

A manufacturing method and liquor technology, which are applied in the preparation of alcoholic beverages, chemical instruments and methods, pharmaceutical formulations, etc., can solve the problems of reducing the production speed of products, unable to obtain SOD liquor, affecting the production speed of liquor, etc., so as to improve the conditioning Efficacy and nutrients, the effect of promoting human metabolism and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

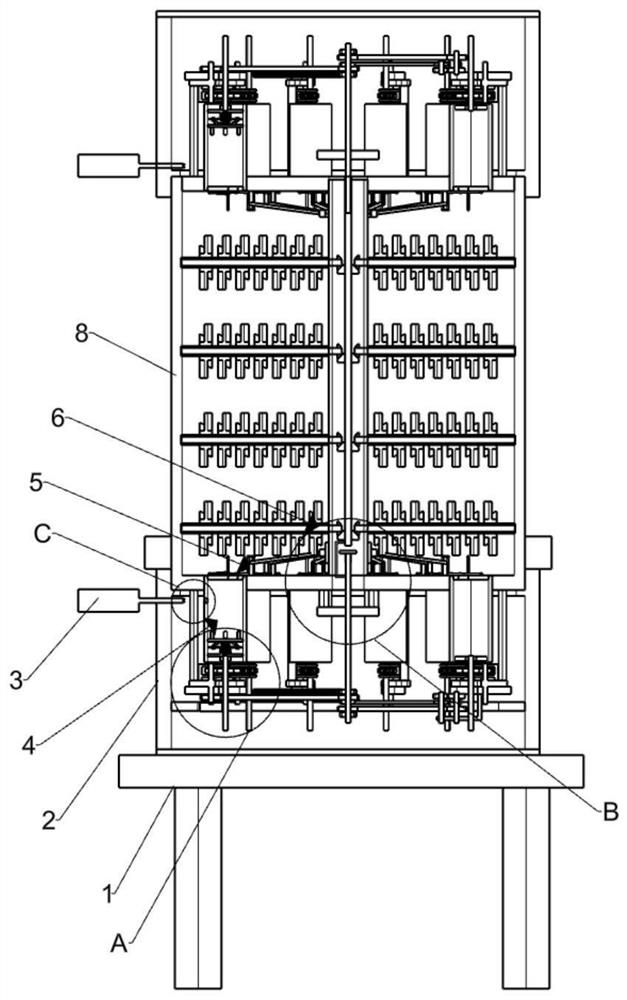

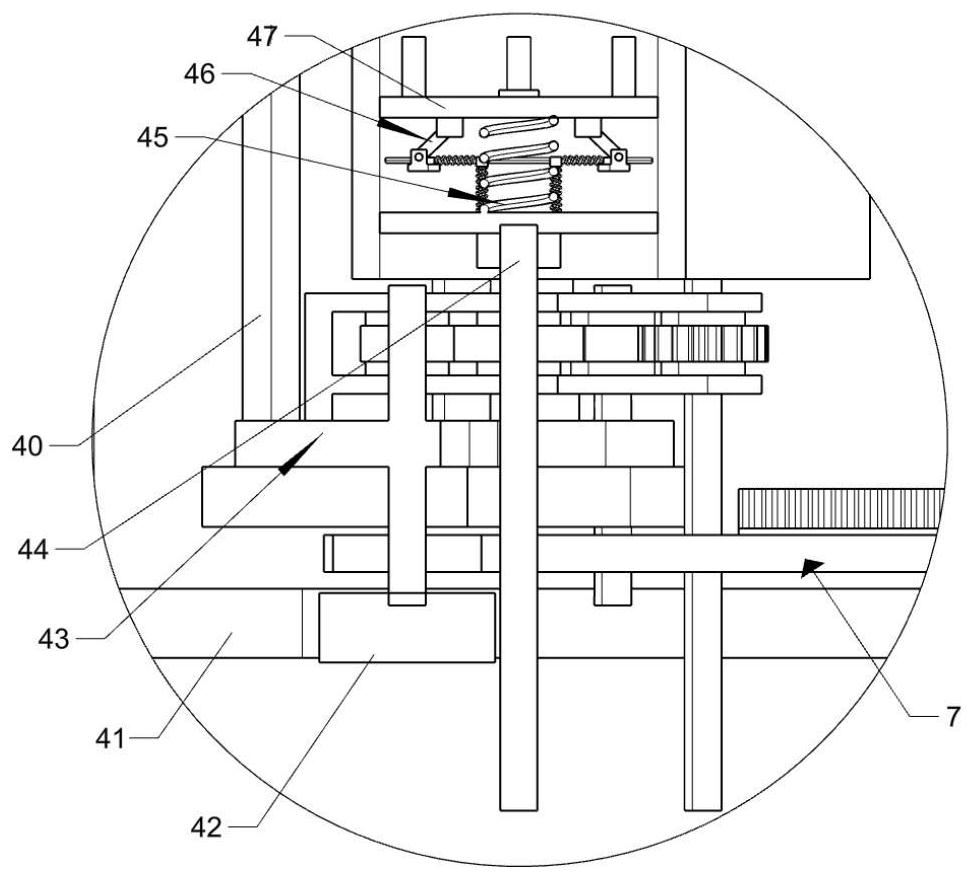

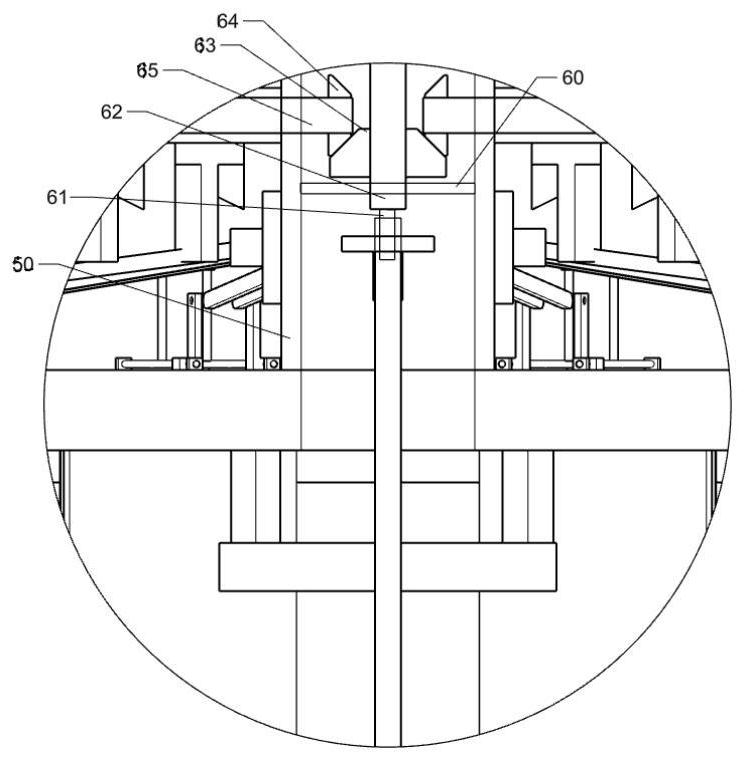

[0053] Such as Figure 1-24 Shown, a kind of SOD liquor manufacture method comprises the following steps:

[0054] Step A. Preparation: 1% ginseng, 1% Cordyceps sinensis, 0.5% American ginseng, 2% Ganoderma lucidum, 1.5% antler, 1.5% Polygonum multiflorum, 1.5% Poria cocos, 1% safflower, 1% deer whip, 3% Chinese yam, 2.5% jujube , royal jelly 70%, sea dragon 2.5%, gecko 2%, also includes 5% of liquor with a concentration of not less than 55%, and 508% of liquor with a concentration of not less than 45%;

[0055] Step B. Extraction: Wash 1kg each of ginseng, cordyceps sinensis, American ginseng, ganoderma lucidum, antler, fleece-flower root, poria cocos, safflower, deer whip, yam, wild jujube, royal jelly, sea dragon and gecko, and then add 2000ml of filtered water separately , using steam pressure cooker equipment for high temperature and high pressure extraction;

[0056] Step C, feeding: adding the extract extracted in step B to the discharge cylinder in the mixing and sti...

Embodiment 2

[0071] A kind of SOD liquor manufacture method, comprises the following steps:

[0072] Step A. Preparation: 1.5% ginseng, 1.5% Cordyceps sinensis, 0.7% American ginseng, 2.5% Ganoderma lucidum, 1.7% antler, 1.2% Polygonum multiflorum, 1.3% Poria cocos, 1.5% safflower, 1.5% deer whip, 4% Chinese yam, 3% jujube , royal jelly 8%, sea dragon 2.6%, gecko 2.5%, also including 6% of liquor with a concentration of not less than 55%, and 60% of liquor with a concentration of not less than 45%;

[0073] Step B. Extraction: Wash 1kg each of ginseng, cordyceps sinensis, American ginseng, ganoderma lucidum, antler, fleece-flower root, poria cocos, safflower, deer whip, yam, wild jujube, royal jelly, sea dragon and gecko, and then add 2000ml of filtered water separately , using steam pressure cooker equipment for high temperature and high pressure extraction;

[0074] Step C, feeding: adding the extract extracted in step B to the discharge cylinder in the mixing and stirring device;

[0...

Embodiment 3

[0079] A kind of SOD liquor manufacture method, comprises the following steps:

[0080] Step A. Preparation: Ginseng 2%, Cordyceps 2%, American Ginseng 1%, Ganoderma lucidum 3%, Antler 2%, Polygonum multiflorum 1.5%, Poria cocos 1.5%, Safflower 2%, Deer whip 2%, Chinese yam 5%, Zizyphus jujube 4% , 10% royal jelly, 3% sea dragon, 3% gecko, 8% of liquor with a concentration of not less than 55%, and 68% of liquor with a concentration of not less than 45%;

[0081] Step B. Extraction: Wash 1kg each of ginseng, cordyceps sinensis, American ginseng, ganoderma lucidum, antler, fleece-flower root, poria cocos, safflower, deer whip, yam, wild jujube, royal jelly, sea dragon and gecko, and then add 2000ml of filtered water separately , using steam pressure cooker equipment for high temperature and high pressure extraction;

[0082] Step C, feeding: adding the extract extracted in step B to the discharge cylinder in the mixing and stirring device;

[0083] Step D, mixing and stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com